The mud-stone separator, a core piece of equipment specifically designed to separate mud and sand, achieves efficient separation of mud and sand by precisely differentiating the physical properties of materials such as particle size and density. This lays the foundation for the recycling and reuse of sand and gravel resources and the harmless treatment of mud. Its performance directly affects the ...

Clarifying the functional differences between trommel screens and vibrating screens is not only a technical prerequisite for equipment selection, but also the foundation for improving the scientific nature of construction waste screening operations

The trommel screen for garbage screening is an efficient classification process based on physical principles, relying on precision structures, and achieved through standardized processes.

The precautions for using a drum screen run through the entire process of equipment start-up, operation, shutdown, and long-term maintenance, and standardized operation at every step is crucial.

The efficiency and accuracy of landfill waste sorting equipment are crucial. Efficient sorting equipment can process large amounts of garbage in a short period of time, reducing labor and time costs.

This article focuses on the current development status of drum screen technology, analyzes core innovation points, and predicts future trends, providing reference for industry development.

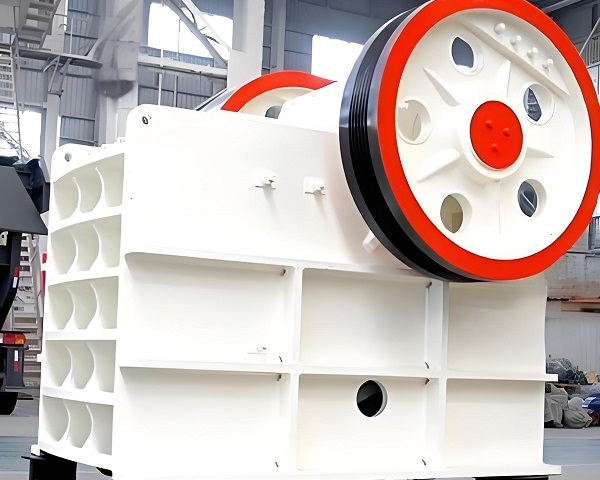

A thorough analysis of the characteristics and advantages of the European-style jaw crusher, clarifying its application advantages compared to traditional models, has important guiding significance for enterprises' equipment selection and production upgrades.

The structural features of the bar screen are closely related to its core advantages. The scientific bar arrangement, stable vibration system, and robust frame structure together create its advantages of anti-clogging, high wear resistance, and large throughput.

Improving the crushing efficiency of jaw crushers is a systematic project that requires coordinated efforts from multiple dimensions, including equipment selection, feed control, parameter optimization, maintenance, and technological upgrades.

As a key pretreatment device in industrial production, the bar screen's screening effect directly affects the efficiency and cost of subsequent production processes.