In the screening process of construction waste resource utilization, trommel screens and vibrating screens are the two most widely used core equipment. Although both aim to achieve material grading as their core goal, there are significant differences in functional characteristics, applicable scenarios, screening effects, and other aspects based on different working principles and structural designs. The composition of construction waste is complex and diverse, including hard concrete blocks, crushed stones, sticky soil, dust, as well as lightweight plastics and sawdust. Choosing the appropriate screening equipment directly determines the processing efficiency and quality of recycled products in the project. Thoroughly clarifying the functional differences between trommel screens and vibrating screens, and scientifically selecting based on actual working conditions, is a key prerequisite for improving the economic and practical efficiency of construction waste screening operations. This article will comprehensively analyze the functional boundaries and application value of two types of devices from dimensions such as working principles, structural features, core functional differences, applicable scenarios, and comprehensive performance comparison.

The essential difference in working principle is the core source of the functional difference between trommel screens and vibrating screens, which directly determines their screening logic and performance characteristics. The trommel screen is based on the core principle of "rotating classification", and its key working component is the tilted cylindrical screen cylinder. The motor drives the screen cylinder to rotate uniformly around the axis through the transmission system. When construction waste enters the sieve tube, it undergoes a spiral rolling and movement along the axis of the sieve tube under the combined action of gravity, centrifugal force, and frictional force on the inner wall of the sieve tube. During this process, material particles with a particle size smaller than the sieve aperture continuously fall through the sieve aperture to form undersized products, while materials with a particle size larger than the sieve aperture are transported to the end of the sieve cylinder for discharge, completing the classification process. This combination of "dynamic conveying+static screening" ensures that the material remains in a continuous flow state inside the screening cylinder, and the screening process is gentle and stable.

The vibrating screen is based on the core principle of "vibration excitation", and its screening body is a fixed screen box with a sieve mesh. High frequency and high-intensity vibration energy is generated through the exciter. The exciter is usually composed of eccentric shaft, eccentric block and other components, which drive the sieve box to perform periodic reciprocating vibration during operation, causing the construction waste particles inside the box to produce violent jumping and rolling on the sieve surface. The material continuously changes its motion trajectory under the action of vibration, and comes into high-frequency contact with the sieve. Particles with a particle size smaller than the sieve hole quickly pass through the sieve, while particles larger than the sieve hole move along the sieve surface to the discharge end under the action of vibration thrust. This "forced vibration+high-frequency screening" mode enhances the relative motion between the material and the sieve through external excitation, resulting in higher screening efficiency but more intense process. Two completely different working principles fundamentally determine a series of differences in functional performance between the two types of devices.

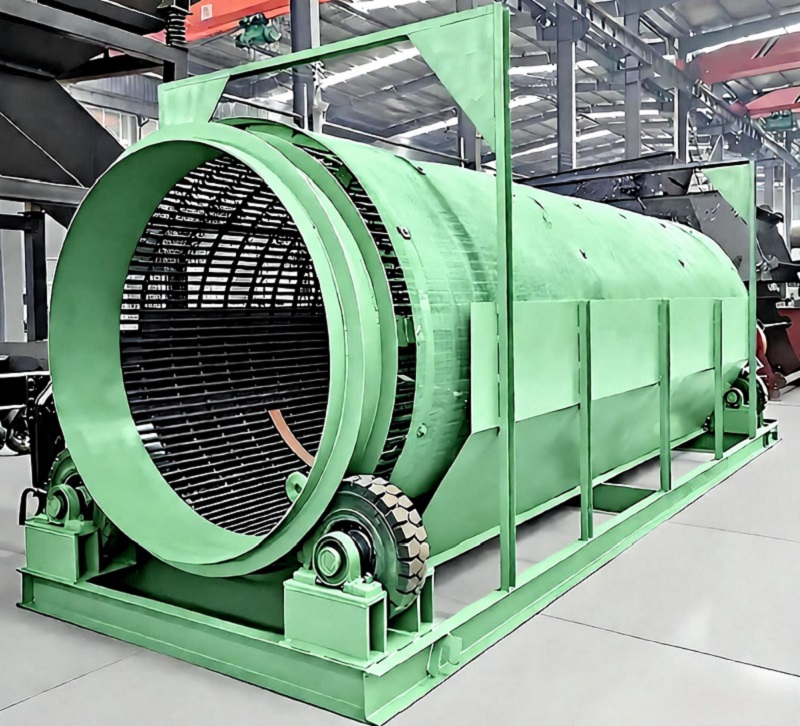

The difference in structural design further amplifies the functional differences between the two, and the configuration and functional logic of each core component form a sharp contrast. The core structure of the trommel screen revolves around the "rotating screen cylinder", mainly composed of the screen cylinder, transmission system, support system, and feeding and discharging devices. The sieve cylinder is a key functional component, which adopts a cylindrical structure and is equipped with a lifting plate on the inner wall to enhance the rolling effect of materials and avoid local accumulation; Screens are often made of materials such as high manganese steel and wear-resistant alloys, and can be designed as single-layer or multi-layer structures according to screening requirements to achieve multi-level grading. The transmission system often adopts belt or chain transmission to ensure the uniform rotation of the screen cylinder; The support system consists of supporting wheels, blocking wheels, and shock-absorbing bases, ensuring stable operation of the screen cylinder while reducing vibration transmission.

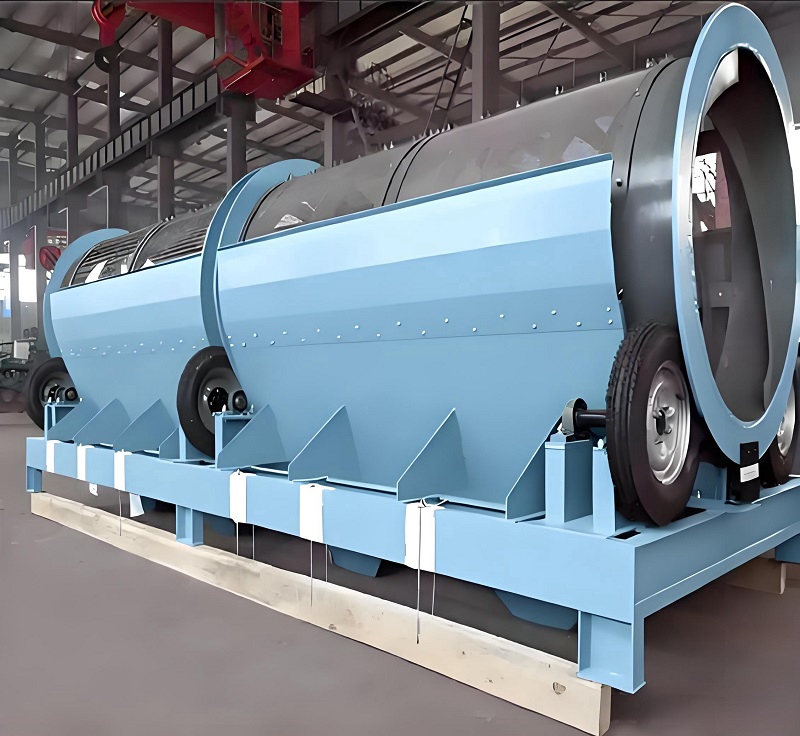

The core structure of the vibrating screen focuses on the "vibrating screen box", which mainly includes the screen box, exciter, damping system, support device, and screening system. The screening box is a rigid frame structure with multiple layers of screens fixed inside, forming screening areas with different aperture sizes; The exciter is the power core, which can be divided into eccentric block type, electromagnetic type, etc. Among them, the eccentric block type exciter is the most widely used in construction waste treatment due to its high vibration intensity and flexible adjustment. The shock absorption system is composed of spring components, which can effectively absorb the impact of screen box vibration on the equipment base and site; In the screening system, the mesh installation adopts a tensioned structure, which is easy to replace quickly and can improve the service life of the mesh. The difference in structural design makes the trommel screen more focused on "grading in stable conveying", while the vibrating screen emphasizes "efficient separation under forced vibration", and the functional orientation is clear at a glance.

In terms of core screening function, the differences between the two are mainly reflected in four dimensions: classification accuracy, processing efficiency, anti blocking performance, and material adaptability. In terms of grading accuracy, vibrating screens perform better with the advantage of high-frequency vibration. The high-frequency vibration of the vibrating screen causes the material to bounce violently on the screen surface, and the collision and separation between particles are stronger, which can effectively break the agglomeration phenomenon between fine particles and ensure the precise separation of particles with a diameter close to the sieve hole. For example, when dealing with construction waste with high mud content, the vibration effect of the vibrating screen can shake off the fine mud adhering to the surface of the coarse aggregate, making the particle size distribution of the screened products more uniform, and the purity of the recycled aggregate can reach over 90%. The screening process of the trommel screen is relatively mild, and the rolling strength of the material inside the screen cylinder is limited. The separation accuracy of particles near the critical particle size is low, and a small amount of fine aggregate is easily mixed into the screened product, with a purity usually around 85%.

The comparison of processing efficiency requires distinguishing scenarios based on material characteristics. For large and high hardness construction waste (such as concrete blocks with a particle size of 50mm or more), the advantages of trommel screens are more obvious. The rotating screening cylinder can accommodate a large amount of materials, which are screened during the conveying process. The processing capacity per unit time can reach hundreds of tons, and it is not easy to cause equipment failure due to the impact of large materials. The bearing capacity of the vibrating screen surface is relatively limited, and large pieces of material are prone to accumulate on the screen surface, causing blockage. It is necessary to control the feeding amount, and the efficiency of processing large particle materials is usually about 30% lower than that of a trommel screen. But when dealing with fine particulate materials (such as sand and gravel mixtures with a particle size of less than 20mm), the high-frequency vibration of the vibrating screen enables the fine particles to pass through quickly, and the processing efficiency surpasses that of the trommel screen, especially in scenarios where rapid separation of fine aggregates is required.

The anti blocking performance is a key indicator of the difference in performance between two types of equipment in construction waste treatment, which directly affects the continuous operation capability of the equipment. The trommel screen has a natural anti blocking advantage due to its unique rotating structure. During the rotation of the sieve cylinder, the material is always in a dynamic rolling state, and the lifting and scattering actions of the plate can effectively prevent the material from accumulating on the surface of the sieve; For materials with strong viscosity (such as soil with high moisture content), centrifugal force can promote their sliding on the inner wall of the sieve cylinder, reducing the probability of adhesive blockage of the sieve holes. When dealing with construction waste with a mud content of over 20%, the trommel screen can run continuously for several hours without cleaning the screen mesh, while the vibrating screen needs to be shut down frequently to deal with blockage problems.

The anti blocking performance of vibrating screens is relatively weak, with the screen surface fixed and relying solely on vibration to achieve material separation. When dealing with viscous materials or construction waste containing fibers, plastics, and other impurities, fine particles are prone to adhere to the edges of the sieve holes, forming a "bridging" phenomenon, while fiber impurities are prone to wrap around the surface of the sieve, causing blockage of the sieve holes. Although some vibrating screens are equipped with auxiliary anti blocking devices such as ultrasonic cleaning and rubber ball striking, it is still difficult to completely solve the problem of blockage in the handling of high viscosity and high impurity materials. Regular manual cleaning is required, which increases operation and maintenance costs and downtime. The difference in anti blocking performance makes the trommel screen more stable in the treatment of complex construction waste.

The differences in material adaptability determine the application boundaries of trommel screens and vibrating screens in different construction waste treatment scenarios. The material adaptability of the trommel screen is more inclined towards the scenario of "rough processing and large impurities", especially suitable for processing construction waste with complex components and large impurities. Its sieve cylinder has a large capacity and can accommodate materials with significant size differences, making it less likely to shut down due to the mixing of a small amount of oversized materials (such as unseparated brick masonry); The gentle characteristics of rotary screening make the equipment more resistant to high hardness materials, and the screen wear rate is slower. When processing hard materials such as concrete blocks and crushed stones, the service life of the screen can reach 3-6 months. In addition, the trommel screen has a wider adaptability to material moisture content, and viscous materials with moisture content below 30% can be stably processed without additional drying or pretreatment.

The material adaptability of vibrating screens focuses on the demand for "refinement and high purity", and is more suitable for processing construction waste that has undergone preliminary pretreatment and has relatively single components. Its high-frequency vibration characteristics have obvious advantages in fine particle grading, which can accurately separate soil impurities in sand and gravel, and produce high-quality aggregates that meet the standards of recycled concrete; For materials with significant density differences, such as metal and sand gravel mixtures in construction waste, vibrating screens can enhance separation efficiency by adjusting vibration parameters to assist in improving resource recovery rates. However, vibrating screens are sensitive to material hardness and size, and when handling large pieces of material with a particle size exceeding 50mm, it can easily cause damage to the screen mesh or malfunction of the exciter; For viscous materials with a moisture content exceeding 20%, the screening efficiency will significantly decrease, and dehydration equipment needs to be used in conjunction.

In terms of operational performance and maintenance costs, the functional differences between the two types of equipment are equally significant, directly affecting the long-term economy of the project. In terms of energy consumption and noise performance, trommel screens have significant advantages. The rotation speed of the sieve cylinder is gentle (usually 5-15r/min), and the motor power requirement is low. When processing the same amount of construction waste, the energy consumption is only 60% -70% of that of the vibrating screen; During operation, mechanical transmission noise is mainly generated, with decibel levels controlled below 75dB. Simple sound insulation measures can meet urban environmental standards. Due to high-frequency vibration (usually 15-30Hz), the power consumption of the motor and exciter of the vibrating screen is relatively high, resulting in high energy consumption; During the vibration process, the impact between the screening box and the supporting structure will produce strong noise, with decibel values generally exceeding 85dB. Professional shock absorption and sound insulation systems are required to meet urban operation requirements.

In terms of operation and maintenance costs and equipment lifespan, each has its own advantages and disadvantages. The core vulnerable component of the trommel screen is the sieve mesh. Due to the mild screening process, the sieve mesh wears out slowly, the replacement cycle is long, and the replacement cost is relatively low; The transmission system has a simple structure and low maintenance difficulty. It only requires regular replenishment of lubricating oil on a daily basis, and the annual operation and maintenance cost is about 5% -8% of the equipment purchase cost. The vulnerable parts of vibrating screens are more diverse. In addition to the screen mesh, the bearings, shock-absorbing springs, and other components of the exciter need to be replaced regularly, especially when dealing with hard materials. The wear rate of the screen mesh is fast, and the replacement frequency is 2-3 times that of the trommel screen; The maintenance technology requirements for vibration exciters are high and require professional personnel to operate. The annual operation and maintenance cost can reach 10% -15% of the equipment purchase cost. However, the response speed of the vibrating screen equipment is faster, and it can quickly reach a stable operating state after starting, while the trommel screen needs to go through 3-5 minutes of idle preheating before entering the normal screening state, which is slightly less flexible in intermittent operation scenarios.

In actual construction waste treatment projects, the functional differences between trommel screens and vibrating screens directly determine the selection logic of the two, and in some scenarios, a combination application mode of "complementary advantages" may also be formed. In large-scale demolition waste treatment projects, the process flow of "trommel screen pretreatment+vibrating screen fine screening" is usually adopted: first, large blocks of concrete, brick masonry and other screened products are separated by trommel screen and sent to the crushing system; The screened product enters the vibrating screen for fine classification, separating different specifications of recycled aggregates to meet the production needs of different recycled products. This combination mode not only utilizes the advantages of trommel screens in handling large impurities and preventing blockages, but also leverages the high classification accuracy of vibrating screens to achieve efficient resource utilization of construction waste.

In a single device application scenario, the selection should closely follow the core requirements: if the project focuses on processing untreated raw construction waste and pursues continuous and stable operation with low maintenance costs, a trommel screen is the optimal choice; If the project focuses on the fine processing of recycled aggregates, with high requirements for screening purity and fine particle separation efficiency, and the materials have undergone preliminary impurity removal treatment, then vibrating screens have more advantages. For example, in decoration waste disposal projects, due to the high content of fine sand and cohesive soil in the materials, as well as the low impurities, vibrating screens can achieve efficient classification; In the treatment of construction waste generated during road construction, the stable operation characteristics of the trommel screen are more important due to the presence of a large amount of large crushed stones and mixed impurities.

From the perspective of technological development trends, the functional differences between the two types of devices are further highlighted in the intelligent upgrade. The intelligent improvement of trommel screens focuses on speed adaptation and remote monitoring. Real time monitoring of material flow and composition changes through sensors, automatic adjustment of screen drum speed, and optimization of screening efficiency; The intelligence of vibrating screens focuses on precise control of vibration parameters, combined with AI algorithms to dynamically adjust vibration frequency and amplitude based on material characteristics, while improving grading accuracy and reducing screen wear and energy consumption. In the future, as the resource utilization of construction waste develops towards "refinement and efficiency", the functional positioning of trommel screens and vibrating screens will become clearer. The former focuses on "front-end coarse separation and stable guarantee", while the latter focuses on "back-end fine screening and quality improvement". The collaborative application of the two will become the mainstream mode.

Overall, the functional difference between trommel screens and vibrating screens is not a matter of "superiority or inferiority", but rather a matter of "adaptation". The two are based on different working principles and structural designs, forming complementary functional characteristics: the trommel screen has the core advantages of stability, anti blocking, and low consumption, and is suitable for the coarse classification requirements of complex construction waste; The vibrating screen is characterized by high efficiency, precision, and refinement, meeting the requirements for fine processing of recycled aggregates. In the construction waste resource utilization project, it is necessary to abandon the misconception of "single equipment adapting to all scenarios", and scientifically choose a single equipment or combination application mode based on multidimensional factors such as material characteristics, screening goals, and operating costs, in order to maximize the value of equipment functions and improve the economic and ecological benefits of the project.

In addition, under special operating conditions, the functional differences between the two further amplify the application boundaries. For example, in the scenario of mobile construction waste treatment, the trommel screen is more suitable for integration with the mobile chassis due to its stable structure and low vibration, achieving rapid on-site screening; However, due to the high vibration intensity, vibrating screens require higher stability for mobile devices and require more complex shock absorption systems, which increases the manufacturing cost of the equipment. In harsh environments such as low temperature and high humidity, the rotating structure of the trommel screen is less susceptible to environmental influences and has stronger operational stability; The exciter and electrical system of the vibrating screen are susceptible to low temperatures and require additional insulation devices, which increases the difficulty of maintenance.

Clarifying the functional differences between trommel screens and vibrating screens is not only a technical prerequisite for equipment selection, but also the foundation for improving the scientific nature of construction waste screening operations. With the deepening of the construction of "waste free cities", the functional requirements for screening equipment in the resource utilization of construction waste will continue to increase, and the technological innovation of the two types of equipment in their respective advantageous fields will also continue to deepen. Both the stable and efficient performance of trommel screens and the precise and fine performance of vibrating screens will play an irreplaceable role in the industrial chain of construction waste resource utilization. Scientifically grasping the functional differences between the two and achieving equipment configuration that maximizes the use of resources will become an important support for promoting high-quality development of the industry.

The trommel screen for garbage screening is an efficient classification process based on physical principles, relying on precision structures, and achieved through standardized processes. The core lies in utilizing the mechanical effect generated by the rotation of the sieve cylinder, combined with different aperture screens, to separate garbage materials according to particle size. Reasonable structural design, scientific parameter regulation, standardized operating procedures, and a sound maintenance system are the key to ensuring the screening effect. In the context of the resource utilization of construction waste, the trommel screen, with its stable and reliable screening performance, has become an important link between waste collection and recycling. The continuous upgrading of its screening technology will also provide solid equipment guarantee and technical support for promoting the construction of "waste free cities" and realizing the development of circular economy. From both technical principles and practical applications, trommel screens play an irreplaceable role in the field of waste treatment. The scientific and practical nature of their screening mechanism makes them one of the core equipment in construction waste resource utilization projects.