With the continuous upgrading of modern industry and the sustained improvement of resource utilization efficiency, vibrating screens, as key equipment for screening and grading solid materials, are undergoing a profound transformation from traditional mechanization to intelligent, energy-saving, and environmentally friendly processes. Whether in mining, coal, building materials, solid waste treatment, chemical, or new materials fields, the technological level of vibrating screens directly affects the efficiency of production lines and product quality. Studying its development trends not only helps to grasp the direction of industry technological evolution but also has significant implications for achieving green manufacturing and the construction of smart factories.

Overview and Current Status of Vibrating Screens

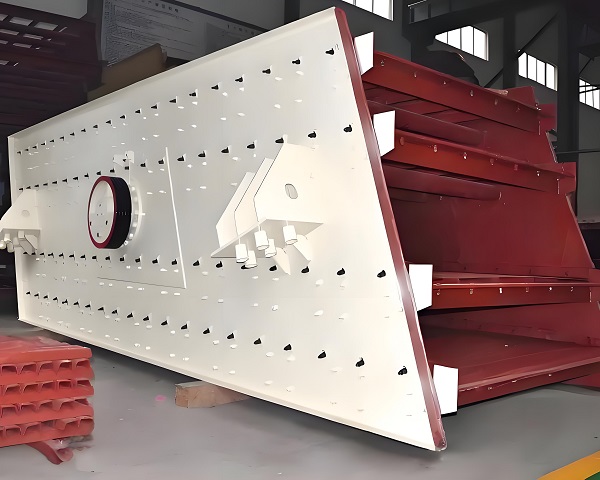

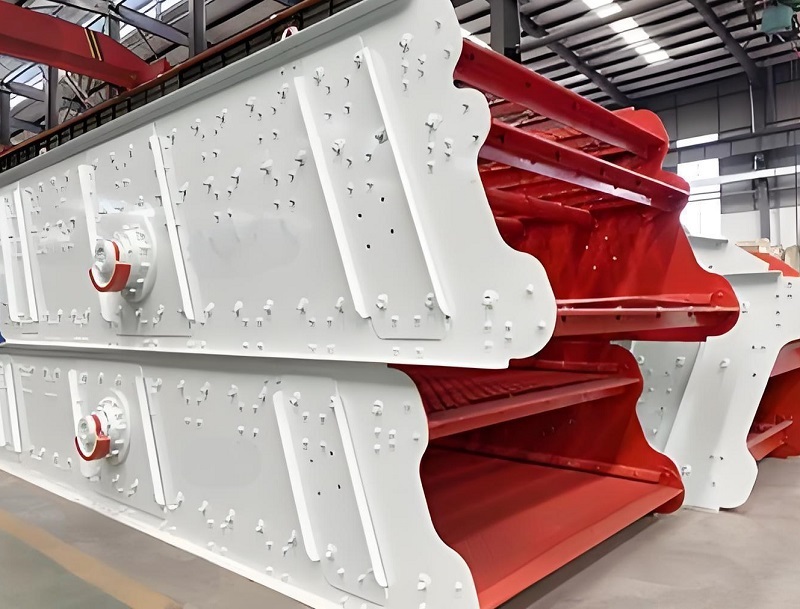

A vibrating screen is a screening device that uses vibration principles to grade, remove impurities, dewater, and deslim materials. It is widely used in mining, coal, metallurgy, building materials, chemical, environmental protection, and food industries. Its basic principle is to generate vibration through a vibrator or vibrating motor, causing the material to move in different forms on the screen surface, thereby achieving particle stratification and separation.

Over the past few decades, vibrating screens have evolved from traditional single-layer, mechanical screening machines to multi-layer, high-frequency, automated, and intelligently controlled modern screening equipment. Significant improvements have been made in screening accuracy, processing capacity, energy consumption, structural reliability, and operational stability. Vibrating screens have become an indispensable core piece of equipment, especially in fields such as new materials, new energy, solid waste treatment, and green mining.

However, with the deepening of industrial automation, intelligent manufacturing, and carbon neutrality strategies, traditional vibrating screens also face new challenges: high energy consumption, high noise levels, short screen life, frequent maintenance, low automation, and insufficient information technology. Therefore, researching and developing more efficient, energy-saving, intelligent, and environmentally friendly vibrating screens has become the mainstream direction of industry development.

Main Development Directions of Vibrating Screens

1. High-Efficiency and Refined Screening Technology

With increasing material processing requirements, the screening accuracy and efficiency of vibrating screens have become key indicators. Future vibrating screens will focus more on the following aspects:

High-Frequency Screening Technology: High-frequency vibration can effectively reduce the "retention effect" between particles and improve the screening rate of fine particles, especially suitable for fine screening scenarios such as micro powder, fine sand, and quartz sand.

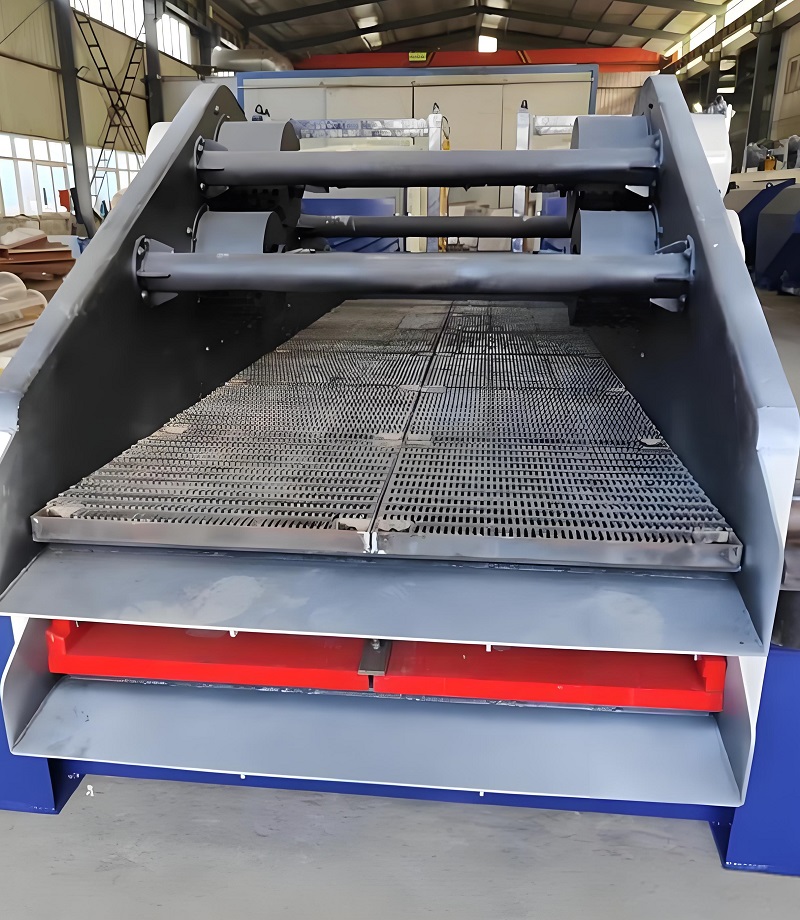

Multi-layer, multi-frequency combined screening: Through a multi-layer structure and multi-vibration source control, synchronous classification of materials with different particle sizes is achieved, improving classification accuracy and production capacity.

Adaptive vibration system: Utilizing variable frequency speed control technology, vibration intensity, frequency, and amplitude can be automatically adjusted according to material characteristics, thus achieving "intelligent screening."

High aperture ratio and anti-clogging screen: Developing new elastic screens, polyurethane screen plates, stainless steel wedge mesh, composite woven screens, and other materials to improve screening throughput and reduce clogging.

The core goal of this trend is to achieve higher processing capacity and screening accuracy without increasing or even reducing energy consumption.

2. Intelligent and information-based control

Intelligentization is one of the important directions for the development of vibrating screen technology. With the widespread application of industrial internet and IoT technologies, vibrating screens are shifting from "passive operation" to "active sensing and intelligent decision-making."

Sensing and monitoring system: Installing sensors for acceleration, displacement, temperature, current, noise, etc., to achieve real-time monitoring of equipment amplitude, frequency, bearing temperature, and screen condition.

Intelligent Diagnosis and Early Warning: Algorithm models detect equipment anomalies such as unbalanced vibration, screen damage, and loose bearings, providing early warnings and automatic shutdown protection.

Data Acquisition and Cloud Management: Vibrating screen operating data can be uploaded to a cloud platform for remote monitoring, data analysis, and maintenance decision optimization.

Production Line Linkage Control: Linkage with upstream crushers and downstream conveyors via PLC or DCS systems forms an intelligent production system.

This trend will significantly reduce the frequency of manual inspections, improve equipment maintenance efficiency, and achieve "unmanned" or "minimal" intelligent screening workshops.

3. Energy-Saving and Environmentally Friendly Design

Energy saving and environmental protection are core concepts in the current equipment manufacturing industry. The energy-saving design of vibrating screens is mainly reflected in the following aspects:

Lightweight Structural Design: Utilizing high-strength alloy steel, composite materials, and optimized welding structures reduces overall machine weight and drive energy consumption.

Low-Energy Vibration System: Optimizing parameters such as vibration direction angle, excitation force distribution, and transmission efficiency reduces energy consumption by 10%–30%. Noise and Dust Control: Developing low-noise motors, vibration-damping springs, fully enclosed dust covers, and sound-absorbing devices ensures equipment noise levels are below 80 dB, meeting environmental protection requirements.

Green Manufacturing and Renewable Materials: Utilizing environmentally friendly coatings and recyclable screen materials reduces harmful emissions.

The market demand for energy-saving and environmentally friendly vibrating screens will continue to expand in fields such as solid waste treatment, construction waste recycling, and mine ecological restoration.

4. Modularization and Improved Maintainability

To adapt to complex working conditions, facilitate rapid installation, and reduce maintenance costs, vibrating screens are developing towards modularization and standardization.

Modular Design: Standardizing the design of components such as vibrators, screen boxes, support structures, and screen plates facilitates replacement, upgrades, and maintenance.

Quick Screen Replacement System: Screen replacement can be completed in minutes using snap-on or sliding rail structures.

Lubrication-Free and Maintenance-Free Components: Employing long-life bearings, automatic lubrication systems, and sealed dustproof designs extends equipment lifespan.

Intelligent Maintenance Platform: Records equipment maintenance cycles and runtime through an IoT system, reminding operators to perform scheduled maintenance.

This trend makes the operation and maintenance of vibrating screens more convenient, especially suitable for mines, coal preparation plants, and large sand and gravel production lines requiring continuous operation.

5. Multifunctionality and System Integration

Modern industrial production increasingly favors integrated and unified designs. Vibrating screens are no longer merely "screening equipment" but have become integral components of the entire material handling system.

Integrated Screening + Conveying: Combining vibrating screens with conveyors and feeders enables continuous operation and reduces intermediate steps.

Screening + Washing/Dewatering Combination Equipment: In the sand, gravel, coal, and mineral processing fields, integrated equipment has emerged that combines vibrating screens with washing tanks, dewatering devices, and recovery systems.

Multi-Process Coupling: Multifunctional equipment such as "screening + air separation," "screening + magnetic separation," and "screening + photoelectric separation" can improve separation purity and efficiency.

Systematic Intelligent Control: Equipment operating parameters can be linked with production planning, energy consumption monitoring, and material analysis systems to form a closed-loop control system.

This trend reflects the "systematization" and "intelligent collaboration" of modern equipment, and provides new paths for enterprises to save investment and improve the automation level of production lines.

Future Technology Outlook

From the perspective of global screening technology development trends, the core competitiveness of future vibrating screens will focus on four dimensions: "intelligence, efficiency, energy saving, and reliability."

1. Artificial Intelligence and Big Data Analysis

Using AI algorithms to identify and analyze vibration signals enables equipment status prediction and adaptive control. For example, AI can automatically adjust amplitude and frequency based on historical operating data to maintain optimal screening results.

2. Digital Twin Technology

By establishing a digital model of the vibrating screen, its operating status can be simulated in real time, predicting vibration modes, load distribution, and fault points, achieving virtual debugging and remote optimization.

3. New Material Applications

Future screens will increasingly utilize wear-resistant composite materials, ceramic liners, and carbon fiber structures to improve lifespan and screening efficiency; vibrating components may incorporate new technologies such as magnetic levitation drives and flexible vibration mechanisms.

4. Parallel Development of Ultra-Large and Ultra-Fine Screening Machines

With the development of large-scale mining and fine chemical industries, vibrating screens will simultaneously extend in two directions: "large-scale" and "ultra-fine." Large-scale screening machines will have higher capacity and reliability, while fine screening machines will pursue micron-level separation accuracy.

5. Green and Low-Carbon Manufacturing

The future manufacturing process of vibrating screens will place greater emphasis on carbon emission control and lifecycle management, implementing green manufacturing concepts throughout the entire process from material procurement, production, transportation to recycling.

The vibrating screen industry is at a critical stage of transformation from traditional mechanical equipment to intelligent, energy-saving, and environmentally friendly equipment. With the advancement of Industry 4.0 and the dual-carbon strategy, future vibrating screens will not only be screening equipment but also important nodes in information collection, data decision-making, and intelligent manufacturing systems.

Continuous innovation in areas such as high-efficiency screening, energy conservation and environmental protection, intelligent control, modular maintenance, and system integration will become the main driving force for the high-quality development of the vibrating screen industry. It is foreseeable that in the next 5-10 years, vibrating screens will rapidly develop towards "high precision, low energy consumption, long lifespan, intelligence, and green technology," becoming a key piece of equipment for more intelligent and sustainable modern industrial production.

The bouncing screen, with its parallel four-bar linkage and dual-axis synchronous design, achieves a light material sorting rate of over 90%, solving the precision and stability problems of traditional equipment. Its modular screen body, fully enclosed structure, and durable configuration ensure a processing capacity of 100-150 tons/hour while controlling dust, reducing noise, and minimizing malfunctions. In application, it improves resource recovery rates, adapts to multiple scenarios, and reduces carbon emissions, offering both economic and environmental benefits. This equipment promotes the transformation of solid waste treatment towards high efficiency and low carbon emissions, providing strong support for the construction of "zero-waste cities" and serving as an important benchmark for technological upgrading in the industry.