Zhongcheng magnetic separator products have been widely used and highly recognized in various industries such as mineral sorting, coal purification, non-metallic ore iron removal, and environmental resource recovery, thanks to their excellent performance, stable quality, and innovative design. The core advantages and significant features of the Zhongcheng magnetic separator will be elaborated in detail from five aspects: technological innovation, performance indicators, structural design, operating costs, and application fields.

1. Magnetic field design and optimization

High gradient and strong magnetic field: The medium range magnetic separator performs particularly well in the field of high gradient magnetic separation. Its equipment usually adopts a special magnetic circuit design, which can generate extremely strong magnetic field strength and steep magnetic field gradient. This is crucial for sorting weak magnetic minerals (such as hematite, pseudo hematite, manganese ore, etc.) and ultrafine particles, which can effectively capture fine magnetic impurities that are difficult to separate with traditional magnetic separators.

Multipole package angle design: By optimizing the number of magnetic poles and package angle design, the action time of magnetic particles in the magnetic field is significantly extended, the number of rolling and adsorption is increased, thereby greatly improving the selection rate and recovery rate of sorting, and reducing the magnetic carrying capacity of tailings.

Magnetic stability and attenuation rate: The high-performance permanent magnet materials (such as neodymium iron boron) selected for the Zhongcheng equipment have been specially treated to ensure the long-term stability of the magnetic system and extremely low magnetic field attenuation rate. This means that even after years of use, the sorting performance of the device can still maintain its design standards, reducing maintenance and replacement costs.

2. Variable frequency speed regulation and intelligent control

Intelligent frequency conversion control system: Most medium range magnetic separators are equipped with advanced frequency conversion speed regulation technology, which can adjust the cylinder speed and feeding speed in real time according to the properties of the selected materials (particle size, concentration, grade fluctuations). This flexible control avoids equipment operating under non optimal conditions and achieves precise control of the sorting process.

Remote monitoring and fault diagnosis: Combined with Industrial Internet of Things (IIoT) technology, equipment can achieve remote monitoring, data collection and analysis, and has automatic fault diagnosis and alarm functions, greatly improving operational convenience and reliability, and reducing reliance on manual experience.

Excellent performance indicators and processing capabilities

Performance indicators are the hard standards for measuring the value of magnetic separators, and mid-range magnetic separators perform excellently in multiple key performance aspects.

1. Extremely high sorting efficiency

Due to optimized magnetic field design and hydraulic conditions, the medium range magnetic separator can achieve:

High selection grade: It can remove harmful impurities (especially iron) from minerals to extremely low levels, such as in the purification of non-metallic minerals (such as quartz sand, potassium feldspar, kaolin), which can effectively reduce the iron content to the level of tens of thousands or even hundreds of thousands, meeting the demand for high-end industrial raw materials.

High metal recovery rate: especially suitable for the enrichment of lean and fine-grained minerals. Through precise magnetic field water flow coupling, valuable magnetic minerals are maximally captured, reducing the loss of useful components with tailings.

2. Strong material adaptability

Zhongcheng magnetic separator has formed a multi series product matrix, which can adapt to materials with different properties:

Wide particle size range: From coarse particles (mm level) to ultrafine particles (μ m level), there are corresponding dry, wet, and high-frequency vibration magnetic separators that can cover the entire beneficiation process from crushing to grinding.

Strong adaptability to concentration: Wet magnetic separators can maintain stable separation effects even when there are significant changes in slurry concentration.

Wide coverage of mineral types: can be used for strong magnetic minerals (such as magnetite), weak magnetic minerals (such as hematite and limonite), non-metallic mineral iron removal, and waste steel slag recycling.

3. Large processing capacity

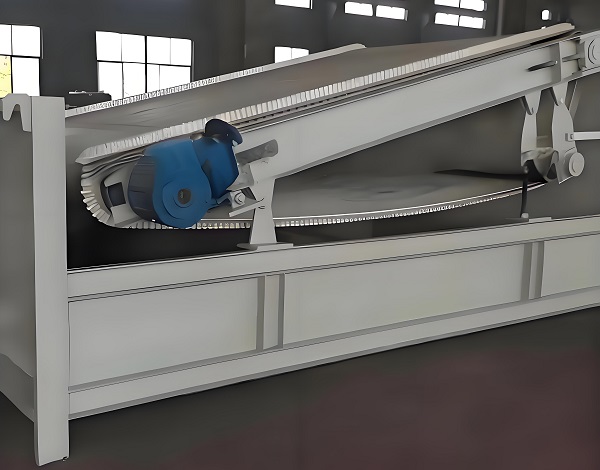

By adopting a large-diameter, large angle drum or cylinder design, as well as optimized fluid dynamics design, the medium range magnetic separator achieves high material processing capacity per unit time, effectively reducing the processing cost per ton of material and meeting the production needs of modern large-scale beneficiation plants.

Structural Design and Reliability Characteristics

The structural design of equipment is directly related to its service life, maintenance frequency, and operational safety.

1. Durable and sturdy structural materials

High wear resistance: The lining plate, scraper and other key components of the cylinder and groove are made of special wear-resistant materials, such as polyurethane, polymer composite materials or special rubber, which greatly extends the service life of the equipment, especially when dealing with highly abrasive minerals, the effect is significant.

Anti corrosion design: In response to the complex chemical environment of wet beneficiation, the equipment surface undergoes professional anti-corrosion treatment to ensure long-term stable operation in humid and acidic environments.

2. Flexible and diverse configuration forms

Zhongcheng magnetic separator provides multiple working modes and structural forms to meet different process requirements:

Wet permanent magnet drum magnetic separator: can be configured as co current, counter current, and semi counter current, suitable for different particle sizes and selection requirements.

Parallel flow: suitable for processes with high requirements for coarse selection and recovery rate.

Counter current type: suitable for the selection of fine-grained materials, with high selection grade.

Semi counter current: Combining the advantages of the first two, it is the most widely used.

Dry magnetic separator: adopting a unique vibration or flipping mechanism, effectively avoiding the adhesion and agglomeration of fine particle materials, and the sorting effect is not limited by water sources.

3. Simplify maintenance and operation

Modular design: The key components adopt modular design, making on-site installation, disassembly, and replacement simple and fast, and shortening maintenance time.

Self cleaning ability: Some models of magnetic separators are designed with automatic flushing or scraper mechanisms, which have a certain self-cleaning function, reducing the frequency and labor intensity of manual cleaning.

Economic benefits and environmental advantages

In today's increasingly focused on economic benefits and environmental protection, the advantages of Zhongcheng magnetic separators are also reflected in their operating costs and environmental characteristics.

1. Low energy consumption operation

Permanent magnet technology: Using high-performance permanent magnets as the magnetic source, there is no need to consume electrical energy to generate a magnetic field, which significantly saves electricity costs compared to electromagnetic magnetic separators.

Optimize the transmission system: Adopt an efficient and low-noise transmission system to minimize the power demand of the driving motor and reduce the total power consumption.

2. Water conservation and environmental protection

Optimization of hydraulic conditions: Accurate water flow control and sorting tank design can achieve optimal sorting results with minimal water volume, effectively saving water resources and meeting the requirements of green mineral processing.

Dry beneficiation technology: Zhongcheng's dry magnetic separation technology is suitable for water scarce areas and does not use water at all, making it an important environmentally friendly beneficiation method.

3. Reduce overall operating costs

The high reliability and low failure rate of the equipment, coupled with simplified maintenance, result in a significantly lower total operating cost (TCO) throughout its lifecycle compared to similar products, bringing users a higher return on investment.

Widely applicable fields

Zhongcheng magnetic separator, with its multi series and customized features, covers almost all industrial fields that require magnetic separation.

Black metal ore beneficiation: purification and enrichment of iron ores such as magnetite, hematite, and limonite.

Purification of non-metallic minerals: removal of iron and magnetic impurities from raw materials such as quartz sand, potassium feldspar, fluorite, kaolin, nepheline, and calcite to improve product whiteness and purity.

Coal industry: recovery of magnetic substances from coal slurry water, as well as desulfurization and ash removal of coal to improve coal quality.

Environmental Protection and Resource Recycling: Metal Recycling from Municipal Solid Waste Incineration Bottom Residue, Iron Recycling from Scrap Steel Slag, and Magnetic Particle Recycling from Sewage Treatment Plant Sludge.

The reason why Zhongcheng magnetic separator has strong market competitiveness lies in its four major characteristics of "high efficiency, stability, energy saving, and intelligence". It is not only a separation device, but also a comprehensive mineral processing solution that integrates high gradient magnetic field technology, frequency conversion intelligent control, and wear-resistant structure design. Whether pursuing the ultimate grade of non-metallic purification or high recovery rate of lean ore enrichment, Zhongcheng magnetic separators can provide stable and reliable technical support to help customers achieve high-efficiency and sustainable mineral processing.