A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Wind Sifter for Sale

Wind Sifter as an air separator or air classifier, is a vital piece of equipment used in various industries such as waste management, recycling, mining, and agriculture. Its primary function is to separate materials based on their density, size, and aerodynamic properties using a controlled stream of air. This process is especially effective for separating light materials (like plastic films, paper, and foils) from heavier substances (such as stones, glass, and metals).

Working Principle

The wind sifting process begins by feeding a mixed stream of materials into the machine. This mixture can include construction and demolition waste, municipal solid waste (MSW), biomass, or compost oversize fractions. As the material enters the sifter, a powerful air stream is generated by a blower or fan system. This air flow lifts the lighter components, allowing them to be carried upward or sideways into a separate discharge area. Meanwhile, the heavier materials fall due to gravity and are collected separately.

Wind sifters can be designed in various configurations, including zigzag separators, cross-flow classifiers, or ballistic separators, depending on the desired application and efficiency. Some systems allow for adjustable air speeds and flow direction to optimize separation for specific material types and moisture levels.

Key Advantages

1. Efficient Separation: Wind sifters can achieve high separation efficiency, removing light contaminants from heavier materials, which improves the quality of recyclable fractions.

2. Versatility: They can handle a wide range of input materials including plastics, paper, glass, wood, organic matter, and more.

3. Non-Contact Sorting: Since wind sifters rely on air currents, there is minimal wear on mechanical parts, reducing maintenance costs and downtime.

4. Energy Efficient: Modern wind sifting systems are designed to be energy-efficient while maintaining high throughput and reliability.

5. Improves Downstream Processes: By removing undesired light fractions early in the process, wind sifters enhance the performance of shredders, optical sorters, and other downstream equipment.

Applications

1. Recycling Facilities: To separate lightweight contaminants from heavy recyclables in plastic, paper, and metal recovery lines.

2.Waste-to-Energy Plants: To clean the feedstock by removing non-combustible or inert materials.

3.Compost Production: To remove plastic films and other light pollutants from organic matter before or after composting.

4.Construction & Demolition Waste: To separate wood and insulation materials from bricks, concrete, and stone.

The Wind Sifter is an essential technology in modern material recovery and waste processing systems. By utilizing air as a separation medium, it offers a low-maintenance, energy-efficient, and highly effective solution for removing lightweight contaminants from heavier valuable materials. Its adaptability to various waste streams and robust design make it a key component in achieving high recycling rates and cleaner material outputs. As environmental regulations become stricter and the demand for resource recovery grows, wind sifters will continue to play a crucial role in sustainable waste management strategies.

Operating principle of Wind Sifter for Sale

A Wind Sifte as an air separator, is a device commonly used in the waste recycling and processing industries to separate materials based on their aerodynamic properties, primarily density and particle size. Its working principle relies on the controlled use of an air stream to sort light and heavy fractions of mixed material streams.

1. Feeding and Pre-Sorting

The material is first fed into the wind sifter through a conveyor or a feeder. Often, the input consists of mixed waste such as construction and demolition debris, municipal solid waste, plastics, paper, and biomass. To enhance efficiency, bulky or oversized items are usually removed in a pre-sorting stage before the material enters the air separator.

2. Air Flow Generation

Inside the wind sifter, a powerful fan or blower generates a high-speed, upward or diagonal airflow. This air stream is carefully calibrated in terms of velocity and direction, and its purpose is to lift lighter materials while allowing heavier ones to fall due to gravity.

3. Separation Process

The mixture of materials is introduced into the separation chamber where the air stream acts upon them:

Lightweight materials (e.g., plastic film, paper, leaves) are caught in the airflow and carried upward or horizontally into a light fraction outlet.

Heavy materials (e.g., stones, wood, glass, metal) are unaffected by the airflow or are only slightly deflected. They fall through the chamber into a heavy fraction discharge area.

In more advanced wind sifters, the airflow is adjustable, and the system may include rotating drums, vibrating feeders, or air ducts that further refine the material trajectory for more accurate separation.

4. Collection and Output

The separated fractions are collected via different output conveyors or chutes. Some systems may have a third “medium fraction” outlet for partially lifted items like small pieces of wood or rigid plastic.

5. Dust and Air Control

Modern wind sifters are equipped with dust collection systems and air recirculation to minimize environmental impact. Air filters or cyclones may be used to clean and reuse air, ensuring the system operates with reduced emissions.

The Wind Sifter works by exploiting the differences in material behavior under the influence of air. By adjusting air velocity and feed parameters, it can achieve efficient separation of light and heavy components, improving recycling rates and reducing landfill loads.

Advantages and features of Wind Sifter for Sale

The wind sifteris a device that uses the differences in material particle size, density and aerodynamic characteristics to separate materials through airflow. It is widely used in many industries and has many significant features and advantages.

Efficient sorting and improved processing capacity: The wind siftercan quickly separate materials of different properties by precisely controlling the airflow speed and direction. In the field of garbage disposal, lightweight plastics and paper can be quickly separated from heavy metals and masonry; in the grain processing industry, it can efficiently remove impurities such as straw and dust from grains. It has strong continuous operation capacity and can achieve a processing capacity of several tons or even tens of tons per hour, greatly improving the material sorting efficiency.

Energy saving and environmental protection, in line with green development: Compared with other sorting methods that rely on complex mechanical or chemical treatment, the wind siftermainly relies on wind power to work and has low energy consumption. At the same time, it does not produce pollutants such as wastewater and waste residue, and does not require the use of chemical agents, which is environmentally friendly. At the moment of advocating green development, the wind siftercan not only meet production needs, but also conform to the concept of environmental protection, helping enterprises achieve sustainable development.

Strong adaptability and wide range of applications: The wind siftercan handle a variety of materials, such as domestic waste, industrial waste, crop straw, Chinese medicinal materials, etc. By adjusting equipment parameters such as wind speed, air volume, sorting angle, etc., it can adapt to the sorting requirements of different materials. Whether it is dealing with fine dust particles or large waste, it can achieve the ideal sorting effect through reasonable settings, and play an important role in different industries.

Simple structure and low maintenance cost: The structure of the wind sifteris relatively simple, mainly composed of fans, sorting chambers, conveying devices and other parts, with fewer parts. This simple structural design makes the equipment failure rate low and convenient for daily maintenance. Operators only need to regularly check the operation of the fan, clean up the residual materials in the sorting chamber, and lubricate key components to ensure the stable operation of the equipment, greatly reducing maintenance costs and downtime.

High degree of intelligence and convenient operation: Modern wind sifter are mostly equipped with intelligent control systems. Operators can easily set sorting parameters through touch screens or computer interfaces and monitor the operation status of the equipment in real time. The system also has a fault diagnosis function. Once an abnormality occurs, it can promptly alarm and prompt the cause of the fault, which is convenient for quick maintenance. Even personnel without professional technical background can operate the equipment skillfully after simple training, which greatly improves the convenience of using the equipment.

Technical Parameter Table of Wind Sifter for Sale

| Model | Airflow Capacity (m³/h) | Material Throughput (t/h) | Power Consumption (kW) | Separation Efficiency (%) | Machine Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WS-500 | 12,000 | 5–10 | 15 | 85 | 3500 × 1800 × 2200 | 1800 |

| WS-800 | 20,000 | 10–20 | 22 | 90 | 4200 × 2000 × 2500 | 2500 |

| WS-1200 | 30,000 | 15–30 | 30 | 92 | 5000 × 2300 × 2800 | 3200 |

| WS-1600 Pro | 45,000 | 25–40 | 45 | 95 | 6000 × 2600 × 3000 | 4500 |

| WS-2000 Max | 60,000 | 35–50 | 55 | ≥96 | 7000 × 3000 × 3200 | 5800 |

If you have any special requirements, we will customize according to your special needs.

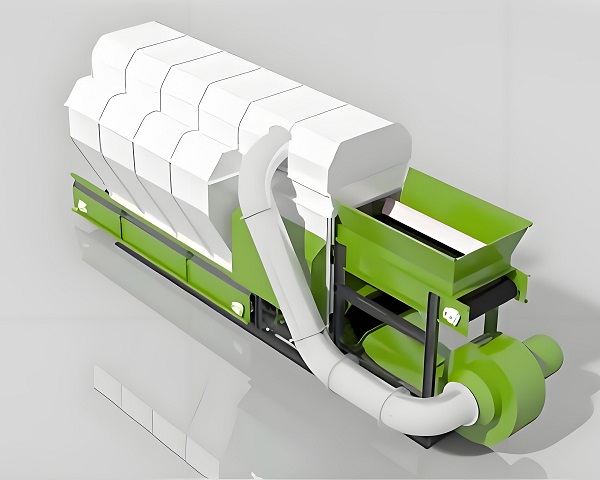

Product Picture Display of Wind Sifter for Sale

FAQ about Wind Sifter for Sale

>Which industries are wind sifters mainly used in?

Widely used in agriculture (such as grain cleaning, seed selection), waste treatment (sorting plastics, paper, metals), food processing (screening nuts, grain impurities), ore primary selection and other fields, used to separate materials of different densities or shapes.

>How to choose a suitable wind sifters model?

The processing capacity, material characteristics (density, humidity, particle size), sorting accuracy requirements and budget need to be considered. For large processing capacity, large models are selected, materials with high humidity require special designs, and high-precision sorting requires models with multi-stage sorting structures.

>What is the difference between a wind sifters and a screening machine?

The wind sifters relies on wind power to separate materials of different densities and is suitable for processing light and easy-to-fly mixtures; the screening machine uses a screen to screen by particle size and is suitable for materials with regular shapes, similar densities but different particle sizes.

>What are the installation steps of the wind sifters?

First fix the main machine, connect the fan, air duct and electronic control system; calibrate the equipment level; debug the fan speed and air volume, check the sealing; run the machine without load to ensure that the equipment runs smoothly and without abnormalities before putting it into use.

>How to maintain wind sifters in daily use?

Regularly clean the residual materials inside the equipment to prevent blockage of the air duct; check the tightness and wear of the fan belt; lubricate the transmission parts; monitor the motor temperature and current to ensure that the fan impeller is free of dust and deformation.

>What should I do if wind sifters has poor sorting effect?

It may be caused by insufficient air volume, blockage of the air duct, excessive material humidity or uneven feeding. It is necessary to adjust the fan speed, clean the air duct, control the material humidity, and adjust the feeding speed and uniformity at the same time.

>What are the safety precautions for operating wind sifters?

It is forbidden to open the equipment protection device during operation; avoid fingers or foreign objects entering the feed port; check the grounding protection regularly; stop the equipment immediately for inspection when abnormal vibration or noise occurs; operators need to wear protective equipment.

>Is the energy consumption of wind sifters high?

The main energy consumption comes from the fan, and its power is related to the processing volume and wind pressure requirements. High-efficiency and energy-saving air separators reduce energy consumption by optimizing air duct design and using variable frequency motors. Large equipment can be equipped with energy-saving control systems.

>Can wind sifters handle wet materials?

Wet materials are easy to agglomerate and block the air duct, affecting the sorting effect, and are generally not recommended for processing. If processing is required, it is necessary to dry it first or choose a special air separator with anti-blocking design and large channel structure.

>What is the service life of wind sifters?

Under normal maintenance, the service life of wind sifters is about 8-12 years. The durability of key components such as fan impellers and transmission bearings, as well as daily cleaning, lubrication and maintenance, directly affect the life of the equipment.

>Can wind sifters sort multiple materials?

Yes, by adjusting the air volume, wind speed and sorting structure, it can sort multiple combinations of materials with obvious density differences, such as plastics and kitchen waste in domestic garbage, lightweight plastics and metals in waste electrical appliances, etc.

>How to control the noise generated by wind sifters?

Noise can be reduced by installing silencers, optimizing fan blade design, adding equipment shock pads, sealing air ducts, etc. At the same time, the equipment should be installed in a soundproof machine room to reduce the impact on the surrounding environment.

>What is the sorting accuracy of wind sifters?

The sorting accuracy of conventional air separators is about 80% - 90%. High-end models equipped with multi-stage sorting and intelligent identification systems can achieve a sorting accuracy of more than 95%, depending on the material characteristics and equipment configuration.

>What are the common causes of wind sifters failure?

Common failures include fan failure (belt breakage, impeller wear), air duct blockage, electronic control system failure, and reduced sorting effect, which are mostly caused by improper operation, insufficient maintenance, and materials that do not meet requirements.