A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Finger Screen for Sale

Finger Screen is a widely used solid waste screening equipment, especially suitable for coarse screening and removal of large foreign matter of materials such as domestic waste, industrial waste, and construction waste. It is named because the screen surface is composed of multiple rows of "finger-like" screen bars, which resemble fingers. Finger Screen uses the relative movement between the material and the screen bars to achieve efficient separation and screening by utilizing the differences in the size and shape of different materials.

The core structure of the equipment is a screen surface composed of several rows of high-strength steel finger bars. The spacing of the finger bars can be flexibly adjusted according to the properties of the material and the sorting requirements. After the material enters the screen surface, smaller particles will fall through the gap between the finger bars, while larger pieces or materials with special shapes will be blocked on the screen surface, achieving effective separation. The screen bars are usually made of wear-resistant and corrosion-resistant materials to ensure long-term and stable operation of the equipment.

Finger Screen has various movement forms, including fixed screen bars plus vibrating screen machine, and screen bars with vibration movement design. The vibration frequency and amplitude are adjustable to ensure that the material is fully dispersed and layered on the screen surface, thereby improving the screening efficiency and accuracy. It has a simple working principle, compact structure, easy maintenance, and low energy consumption.

In practical applications, Finger Screen is often used as the front-end equipment of garbage treatment and recycling production lines to remove large foreign objects (such as wood blocks, cloth, plastic bags, etc.) to prevent subsequent equipment from being blocked or damaged. At the same time, it is also suitable for preliminary classification of fine and large materials to provide a more uniform material flow for subsequent magnetic separation, wind separation, optical separation and other processes.

The main advantages of Finger Screen include simple structure, stable operation, strong processing capacity and wide adaptability. It can effectively deal with domestic waste with high water content and complex mixed components, and the screening effect is reliable and not easy to be blocked. In addition, the automatic lubrication system and replaceable screen bar design equipped with the equipment greatly reduce the difficulty of maintenance and operating costs.

With the development of solid waste treatment and resource recovery technology, Finger Screen has gradually developed in the direction of intelligence and modularization, equipped with automatic control system and remote monitoring function to achieve higher operating efficiency and equipment safety. At the same time, its environmental protection performance is excellent, and the noise and dust emissions during operation are low, meeting the requirements of modern environmental protection regulations.

As an important part of the garbage pretreatment and sorting system, Finger Screen plays an irreplaceable role in solid waste management, resource recovery and reuse with its efficient, stable and flexible screening capabilities. It is a key equipment in modern solid waste treatment plants and circular economy construction.

Operating principle of Finger Screen for Sale

Finger Screen is a mechanical device used for solid waste sorting and material screening. It is widely used in garbage disposal, mine dressing, construction waste and other fields. Its core structure consists of multiple "finger plates" arranged in rows. These finger plates are shaped like fingers and are usually made of wear-resistant steel materials. They rotate or reciprocate through a specific mechanical transmission method to achieve material classification and separation.

The working principle of Finger Screen is mainly based on the differences in size, shape and movement of materials when passing through the screen surface, and the materials are divided into particle sizes of different sizes. After the material enters the screen surface, the smaller particles can fall under the screen through the gaps between the finger plates, while the larger or special-shaped particles are blocked on the screen surface, move forward along the screen surface, and finally discharged from the discharge port.

Finger Screen is usually installed in a horizontal or slightly inclined screen frame. The screen plates are arranged at a certain distance, and the gap size can be adjusted according to the screening requirements. The screen plates are connected by chains or shafts, and are driven by motors to achieve uniform rotation or reciprocating motion. During the rotation process, the material is pushed and shaken by the finger plate. Smaller materials will fall under the screen because their size is smaller than the gap, while larger particles will be separated along the surface of the screen plate because they cannot pass through the gap.

Finger Screen has the advantages of simple structure, easy maintenance, large processing capacity and high separation efficiency. It is particularly suitable for screening large-sized blocks or broken materials with regular shapes, and is also suitable for separating wet and sticky materials because its movement method can effectively prevent materials from blocking the screen gap.

Finger Screen can realize automatic cleaning function. When the material blocks the gap of the screen plate, the rotation or reciprocating motion will drive the finger plates to rub against each other, help clear the blockage and maintain stable screening efficiency. Some modern finger plate screens are also equipped with speed regulating devices, which can adjust the screen plate movement speed according to the material characteristics to optimize the sorting effect.

Finger Screen, with its unique mechanical structure and movement method, can efficiently separate materials of different sizes and shapes, and widely serve many fields such as garbage classification, mine beneficiation, industrial production, etc. It is one of the indispensable key equipment for modern material screening.

Advantages and features of Finger Screen for Sale

Finger Screen is a highly efficient screening equipment widely used in waste treatment, recycling and sorting industries. With its unique screening structure and mechanical design, it excels in processing large, multi-form solid waste, and is particularly suitable for pre-screening and screening of complex mixed materials such as domestic waste, construction waste, and industrial waste.

The core feature of Finger Screen is that it consists of a screen surface composed of multiple finger-shaped steel plates (fingers), which can be fixed or movable to form widely spaced screen holes, which can effectively prevent large pieces of material from clogging and ensure smooth passage of materials. The spacing and arrangement of the finger plates can be flexibly adjusted according to the material characteristics and sorting requirements, so as to achieve accurate screening of materials of different sizes and shapes. Compared with traditional screens, Finger Screen has stronger anti-clogging ability and wear resistance.

Finger Screen is usually made of heavy steel frame and wear-resistant materials to ensure stable operation of the equipment in high-intensity working environments. The sturdiness and rigidity of the screen plate enable it to withstand the impact of large hard objects while reducing the risk of equipment damage caused by impact. In addition, Finger Screen is generally equipped with a powerful vibration or swing drive device to ensure uniform distribution and full separation of materials on the screen surface, thereby improving sorting efficiency.

The advantages of Finger Screen are mainly reflected in the following aspects:

1. Excellent anti-blocking performance: The wide-spaced finger plate design effectively prevents large pieces of material from getting stuck and blocked, and is particularly suitable for handling waste containing a large number of foreign matter and large impurities, ensuring continuous and efficient operation.

2. Strong wear resistance: The screen plate is mostly made of wear-resistant steel, which is suitable for long-term high-speed operation and reduces maintenance frequency and cost.

3. Wide adaptability: It is suitable for a variety of material forms and particle size ranges, and can stably screen both wet and sticky materials and dry and fragile materials.

4. Easy operation and maintenance: The structure is reasonable, the screen plate is easy to disassemble and replace, and the overall maintenance cycle of the equipment is long, reducing operating costs.

5. Efficient screening capacity: Through the reasonably designed vibration and swing mechanism, the dynamic and uniform distribution of materials on the screen surface is ensured, and the sorting accuracy and processing capacity are improved.

6. Flexible application: It can be used as a coarse or medium screen, and is widely used in waste incineration plants, resource recycling centers, construction waste treatment plants, etc. It is also suitable as a pre-screening link for crushers or bag breakers.

Finger Screen has become an indispensable screening tool in the solid waste treatment industry with its unique structure, strong anti-blocking, wear resistance and high-efficiency screening. It effectively improves the stability and processing efficiency of the sorting system, reduces the equipment downtime rate and maintenance costs, and is an important part of modern intelligent solid waste treatment equipment.

Technical Parameter Table of Finger Screen for Sale

| Model | Screen Width (mm) | Screen Length (mm) | Number of Decks | Finger Gap (mm) | Capacity (t/h) | Motor Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| FGS-1200 | 1200 | 3000 | 1 | 80–150 | 10–20 | 5.5 | 3200 × 1400 × 1500 |

| FGS-1600 | 1600 | 3500 | 1 | 80–150 | 20–35 | 7.5 | 3700 × 1800 × 1700 |

| FGS-2000 | 2000 | 4000 | 2 | 100–180 | 30–50 | 11 | 4200 × 2200 × 1900 |

| FGS-2400 | 2400 | 4500 | 2 | 100–180 | 40–65 | 15 | 4700 × 2600 × 2000 |

| FGS-3000 | 3000 | 5000 | 2 | 120–200 | 60–90 | 18.5 | 5200 × 3200 × 2200 |

If you have any special requirements, we will customize according to your special needs.

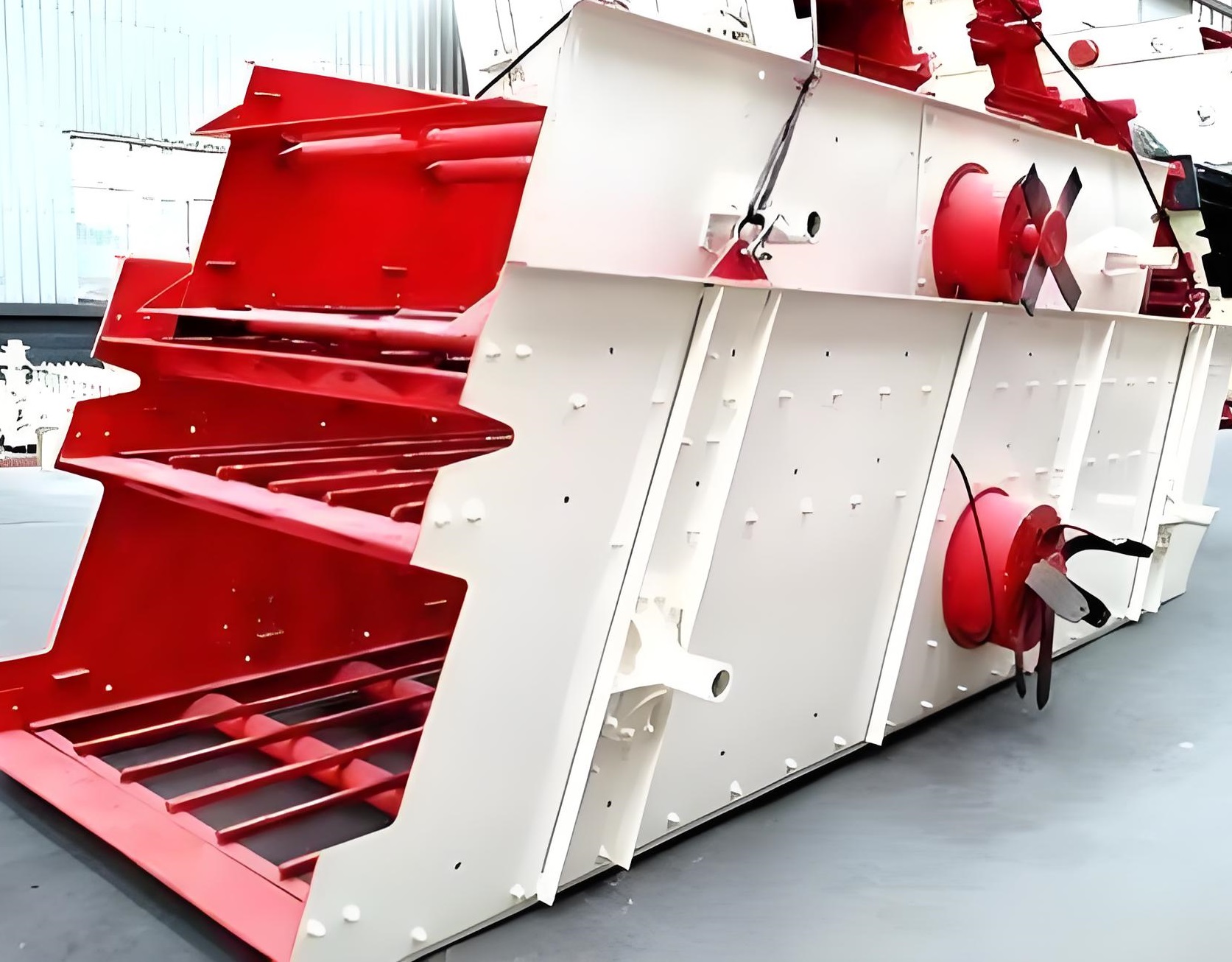

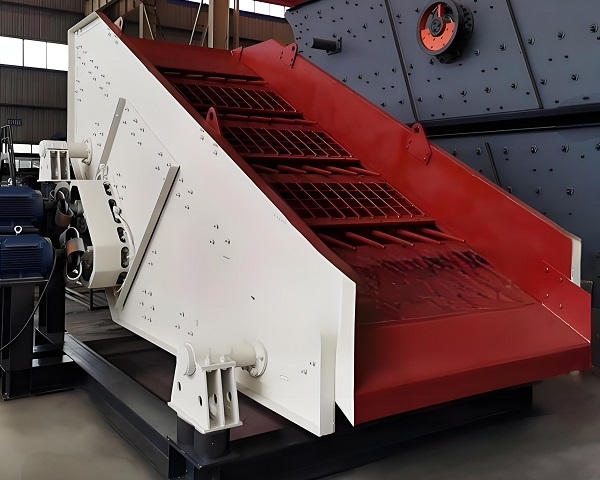

Product Picture Display of Finger Screen for Sale

FAQ about Finger Screen for Sale

>What industries are Finger Screen mainly used for?

In the treatment of construction waste, it is used to separate bricks, concrete blocks, etc.; the mining industry screens ores; the coal industry sorts coal of different particle sizes; the metallurgical industry processes raw materials and waste slag; it is also used in the environmental protection field to treat domestic waste and industrial waste, etc., and plays a key role in the material screening process of multiple industries.

>What types of materials can Finger Screen handle?

It can handle various materials with uneven particle sizes and high humidity, such as construction waste (waste concrete, bricks, wood, etc.), ores (metallic ores, non-metallic ores), coal, coke, sand and gravel, domestic waste (including kitchen waste, plastic, paper and other mixed waste), etc., and is suitable for a wide range of materials.

>What are the advantages of Finger Screen over traditional screening equipment?

Its screen surface structure is special, not easy to clog, and has higher screening efficiency, and can cope with materials with complex characteristics; the equipment runs stably and has strong processing capacity; the finger-shaped screen surface has high strength, wear resistance, long service life, and relatively simple maintenance, which can reduce the overall use cost.

>What are the characteristics of the screen surface material of Finger Screen?

The screen surface is often made of high-strength, wear-resistant metal materials, such as stainless steel. This material is strong and durable, can withstand frequent impact and friction of materials, maintain stable performance under harsh working conditions, reduce the frequency of screen surface replacement, and ensure continuous and efficient operation of the equipment.

>How to adjust the screening effect of Finger Screen?

The vibration intensity of the screen surface can be changed by adjusting the frequency and amplitude of the vibration motor; the screen surface inclination angle can be adjusted to control the length of time the material stays on the screen surface and the movement path; and the finger-shaped screen plates with different spacings can be replaced according to the characteristics of the material to achieve precise control of the screening effect.

>What are the daily maintenance tasks of Finger Screen?

Daily inspection of the vibration motor and connecting parts for looseness and wear; cleaning of materials adhering to the screen surface to ensure smooth screen holes; regular lubrication of key parts such as bearings; check whether the screen plate is deformed or damaged, and repair or replace damaged parts in time to maintain the good operation of the equipment.

>How to measure the processing capacity of Finger Screen?

It is usually measured by the weight or volume of materials processed per unit time. The processing capacity is affected by factors such as equipment model, screen surface specifications, material characteristics, and vibration parameters. Large equipment can process tens or even hundreds of tons per hour to meet the needs of large-scale production.

>What role does Finger Screen play in the field of environmental protection?

In the treatment of domestic waste, it can initially screen the garbage to separate recyclables from non-recyclables; when treating industrial waste, it helps to separate resource recycling from hazardous substances, reduce waste emissions, reduce environmental pollution, and promote resource recycling in the environmental protection industry.

>Is Finger Screen complicated to install? Does it require a special foundation?

The installation is not complicated, but a stable foundation is required to support the vibration of the equipment. Generally, a concrete foundation needs to be built to ensure that the foundation is level and the load-bearing capacity meets the standards. During installation, the components are accurately connected according to the process, and the manufacturer usually provides installation guidance and technical support.

>What faults may occur when using Finger Screen?

There may be problems such as vibration motor failure (failure to start, abnormal speed, etc.), screen plate wear and breakage, loose connection parts, and material blocking the screen surface, resulting in reduced screening efficiency. Regular inspections are required to promptly investigate and solve potential faults.

>What is the particle size range of materials that Finger Screen can handle?

By selecting finger-shaped screen plates with different spacings, it can handle materials ranging from fine particles (millimeter level) to larger blocks (several centimeters or even larger). It can flexibly adapt to different material particle size requirements and realize diversified screening operations.

>What is the energy consumption level of Finger Screen?

Energy consumption is related to equipment power, operating time, and material processing volume. The equipment design focuses on energy saving. By optimizing the vibration system, it can reasonably control energy consumption while ensuring efficient screening and reduce enterprise operating costs.

>What factors will affect the service life of Finger Screen?

Material properties (such as hardness, corrosiveness), frequency of use, maintenance status, equipment quality, etc. High hardness and corrosive materials accelerate equipment wear; frequent use increases losses; regular maintenance can extend life; high-quality equipment itself is more durable.