A Trommel Screen is a rotary drum screening machine widely used in waste processing, mining, and construction industries. It efficiently separates materials by ......

What is the Trommel Screen for Sale

The Trommel Screen is a widely used mechanical device in the field of material screening. With its unique structural design and efficient screening performance, it plays an important role in industries such as mining, construction, and environmental protection.

The trommel screen mainly consists of a motor, reducer, drum unit, frame, sealing cover, feed inlet, and discharge outlet. Its core component, the drum unit, is typically fitted with screens of various specifications, with mesh sizes customized according to specific screening requirements. During operation, the motor drives the drum unit to rotate slowly through the reducer. Materials enter the interior of the drum from the feed inlet. As the drum rotates, materials smaller than the mesh size fall through the screen under the combined effects of gravity and drum rotation, becoming undersized material. Materials larger than the mesh size continue to move forward along the inner wall of the drum and are eventually discharged from the outlet as oversized material, thereby achieving material classification and separation.

Compared with traditional screening equipment, the trommel screen offers several notable advantages. First, it uses a rolling transport mechanism, which has a low friction coefficient and allows for smooth material transport, effectively preventing material clogging and significantly improving screening efficiency. Second, the trommel screen features good sealing performance, which reduces dust dispersion during screening, improves the working environment, and minimizes health risks for operators—meeting environmental protection standards. Third, the equipment operates with low noise, and its simple structure makes installation, commissioning, and maintenance more convenient, thereby reducing operational costs. Fourth, the trommel screen has strong adaptability; by adjusting the drum speed or replacing screens with different mesh sizes, it can screen various materials such as ores, sand and gravel, municipal solid waste, and construction debris, meeting the needs of different industries and working conditions.

In practical applications, the mining industry uses trommel screens for the preliminary screening of extracted ores, separating them by particle size in preparation for further processing. In the field of construction waste treatment, the trommel screen can separate bricks, concrete blocks, metals, and soil, enabling the resourceful reuse of construction waste. In municipal waste management, trommel screens help sort mixed waste, providing convenience for subsequent classification and recycling processes.

Operating principle of Trommel Screen for Sale

The Trommel Screen is a highly efficient screening device that classifies and separates materials using a rotating cylindrical drum. It is widely used in various industries, including mining, construction materials, metallurgy, chemical engineering, and environmental protection. Its core working principle relies on the rotary motion of the drum and the differences in screen aperture sizes to achieve automatic separation and classification of materials.

The trommel screen primarily consists of a motor, reducer, drum unit, frame, sealing cover, feed inlet, and discharge outlet. During operation, the motor drives the drum—mounted on the frame—through the reducer to rotate at a slow and uniform speed. The material to be screened enters the drum through the feed inlet. As the drum rotates, under the combined effects of gravity and centrifugal force, the material inside is continuously lifted, tumbled, and slid, which helps distribute it evenly across the screen surface.

The outer surface of the drum is usually fitted with screens of varying apertures. During the rotation, particles smaller than the screen openings fall through the mesh and are discharged as undersized material via a designated outlet. Particles larger than the screen openings cannot pass through the mesh and continue to move forward along the inner wall of the drum, eventually exiting through the discharge outlet as oversized material. In this way, the trommel screen effectively accomplishes the grading and separation of materials.

The high screening efficiency of the trommel screen is mainly attributed to its “rolling screening” mechanism. Compared to traditional vibrating screens, the trommel screen is less prone to clogging, especially when handling sticky or high-moisture materials, making it more stable during operation. Moreover, by adjusting the drum’s inclination, rotation speed, and replacing screens with different mesh sizes, the equipment can flexibly accommodate a wide range of materials and screening requirements.

Advantages and features of Trommel Screen for Sale

The Trommel Screen is a widely utilized screening device known for its unique structure and operational efficiency. It offers numerous features and advantages that make it highly suitable for a range of applications, including mining, construction, waste management, and environmental protection. Below is a detailed overview of the main characteristics and benefits of the Trommel Screen.

1. Efficient Screening Performance

One of the most significant advantages of the trommel screen is its high screening efficiency. The rotating cylindrical drum allows materials to be continuously turned, tumbled, and exposed to the screen surface, ensuring thorough separation of different particle sizes. Unlike traditional vibrating screens, the trommel screen performs particularly well with wet, sticky, or clay-rich materials, reducing the likelihood of screen clogging and maintaining steady operation.

2. Low Operating Noise and Stable Operation

The trommel screen operates at a relatively low rotational speed, which minimizes noise and mechanical vibrations. This contributes to a more stable working environment and extends the lifespan of both the equipment and its surrounding infrastructure. The rolling motion also places less stress on the machine, resulting in lower wear and maintenance requirements.

3. Flexible and Customizable Design

Trommel screens are highly versatile and can be customized based on specific project requirements. The screen mesh size, drum length, drum diameter, and rotation speed can all be adjusted to meet different material characteristics and desired output sizes. This makes the equipment suitable for a wide range of screening tasks, from fine particle separation to large-scale waste processing.

4. Good Sealing and Environmental Protection

The trommel screen typically features an enclosed drum structure, which significantly reduces dust generation during the screening process. This is particularly beneficial in environments where air quality control is essential, such as recycling plants or construction waste processing sites. By minimizing dust and particulate emissions, the trommel screen helps create a cleaner and safer working environment, aligning with environmental regulations and standards.

5. Ease of Maintenance and Operation

Thanks to its simple structure and modular components, the trommel screen is easy to install, operate, and maintain. Screen replacements, motor servicing, and other routine maintenance tasks can be carried out with minimal downtime. The machine’s robust design ensures durability, reducing the frequency of breakdowns and associated repair costs.

6. Wide Range of Applications

Trommel screens are capable of handling a diverse range of materials, including but not limited to ores, sand, gravel, coal, compost, municipal solid waste, and construction debris. This broad applicability makes the trommel screen an indispensable tool in various industries. In mining, it helps with the preliminary classification of ore; in construction, it separates reusable materials from waste; in environmental sectors, it aids in the recycling and sorting of household and industrial waste.

The Trommel Screen stands out due to its efficient screening capability, low noise, high adaptability, and environmental friendliness. Its rolling screening mechanism not only improves performance but also ensures consistent output quality across different types of materials. With its user-friendly design and strong operational flexibility, the trommel screen proves to be a reliable, cost-effective solution for modern screening needs across a wide spectrum of industries.

Technical Parameter Table of Trommel Screen for Sale

| Model | Production Capacity (t/h) | Power (kw) | Drum Diameter (mm) | Drum Length (mm) | Feed Particle Size (mm) | Under-Sieve Particle Size (mm) | Overall Dimensions (Length x Width x Height, mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| GTS1015 | 50 | 3.0 | 1000 | 1500 | ≤300 | 0 - 100 | 2600x1400x1700 | 2200 |

| GTS1020 | 100 | 4.0 | 1000 | 2000 | ≤300 | 0 - 100 | 3390x1400x2140 | 2800 |

| GTS1225 | 160 | 5.5 | 1200 | 2500 | ≤300 | 0 - 100 | 4146x1600x2680 | 4200 |

| GTS1530 | 250 | 7.5 | 1500 | 3000 | ≤400 | 0 - 100 | 4460x1900x2820 | 5100 |

| TW1545 | 350 | 11 | 1500 | 4500 | ≤400 | 0 - 100 | 5960x1900x3080 | 6000 |

| GTS1848 | 450 | 15 | 1800 | 4800 | ≤400 | 0 - 100 | 6500x2350x4000 | 7500 |

| GTS2055 | 600 | 22 | 2000 | 5500 | ≤400 | 0 - 100 | 7500x2550x4800 | 9600 |

| GTS2265 | 800 | 30 | 2200 | 6500 | ≤400 | 0 - 100 | 8500x2750x5000 | 12800 |

If you have any special requirements, we will customize according to your special needs.

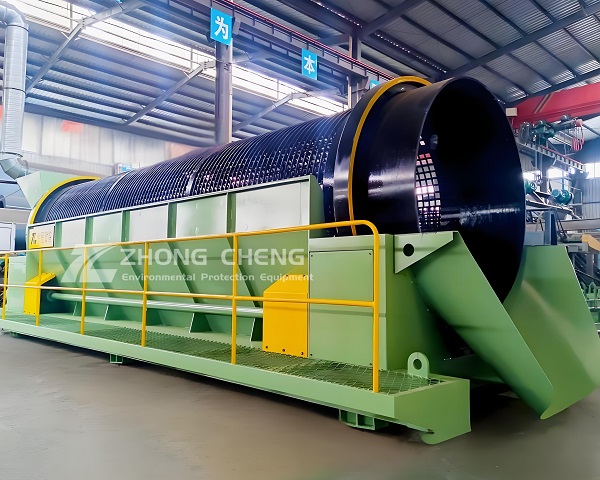

Product Picture Display of Trommel Screen for Sale

FAQ about Trommel Screen for Sale

>What types of Trommel Screen are there?

Mainly divided into two categories: fixed and mobile. Fixed type is suitable for places with fixed sites and large processing capacity; mobile type is equipped with tires or crawler chassis, which can be flexibly transferred and is often used in mobile operation scenes such as on-site treatment of construction waste and mining.

>What materials are suitable for Trommel Screen?

It can handle a variety of materials such as construction waste, domestic waste, soil, sand and gravel aggregates, ores, waste plastics, etc. It is especially suitable for screening loose materials with irregular shapes and moderate humidity to achieve material classification and impurity separation.

>How to choose the right Trommel Screen model?

It is necessary to comprehensively consider the processing capacity, material characteristics (particle size, humidity, hardness, etc.), screening accuracy requirements, site conditions and budget. For large processing capacity, choose large diameter and long drum equipment; for materials with high humidity, choose anti-clogging screens; mobile type is suitable for multi-site operation needs.

>How to choose the Trommel Screen screen?

The screen aperture is selected according to the screening particle size. The commonly used aperture ranges from a few millimeters to tens of millimeters. The screen materials include stainless steel, manganese steel, polyurethane, etc. Stainless steel screens are corrosion-resistant, manganese steel screens are wear-resistant, and polyurethane screens are elastic and anti-clogging.

>What are the installation requirements for Trommel Screen?

Fixed equipment needs to be installed on a flat and solid concrete foundation to ensure levelness; mobile equipment needs to check the stability of the chassis, tires or tracks; after installation, the drum level should be calibrated, and the transmission parts should be checked for firm connection to avoid vibration during operation.

>What are the daily maintenance points of Trommel Screen?

Clean the materials adhering to the screen regularly to prevent blockage; check the wear of the screen and replace the damaged screen in time; lubricate the transmission bearings, chains and other parts; check the operating temperature and noise of the motor and reducer to ensure the normal operation of the equipment.

>What is the reason for the low screening efficiency of Trommel Screen?

It may be that the screen is blocked, the drum speed is improper, the feed is uneven, the screen aperture is inappropriate, or the material humidity is too high. It is necessary to clean the screen, adjust the speed, control the feed amount, replace the appropriate screen, or pre-treat the material to reduce humidity.

>How does Trommel Screen prevent clogging?

Use a screen design with a self-cleaning function, such as a wavy screen and a roller screen; add a screen vibration device; reasonably control the feed speed and material humidity to prevent the material from accumulating and caking on the screen.

>Is the energy consumption of Trommel Screen high?

Its energy consumption mainly depends on the equipment model, processing capacity and running time. Large equipment has a large processing capacity and relatively high energy consumption, but the energy consumption per unit processing capacity is low; energy consumption can be reduced by optimizing motor selection and reducing idling time.

>How long is the service life of Trommel Screen?

Under normal use and maintenance, the overall service life of the equipment can reach 5-10 years. The replacement cycle of key components such as screens, bearings, transmission chains and other wearing parts varies according to the frequency of use and working conditions. The general screen replacement cycle is 6-12 months.

>Can Trommel Screen handle wet materials?

It can handle materials with a certain humidity, but the humidity should not be too high, otherwise it will easily cause the screen to clog. For materials with high humidity, they can be dried or mixed with dry materials first, or screen materials and structures with good anti-clogging effects can be selected.

>What are the safety precautions for Trommel Screen operation?

It is strictly forbidden to open the protective device when the equipment is running, and it is forbidden to put hands or tools into the drum; check the grounding of the equipment regularly; operators need to wear protective equipment; the power must be turned off and a warning sign must be posted before the equipment is repaired.

>What is the future development trend of Trommel Screen?

In the future, Trommel Screen will develop in the direction of intelligence (equipped with automatic monitoring and fault diagnosis system), energy saving and environmental protection (using high-efficiency motors and energy-saving technology), and multi-functional integration (combined with other equipment to form a screening and processing production line) to improve processing efficiency and applicability.