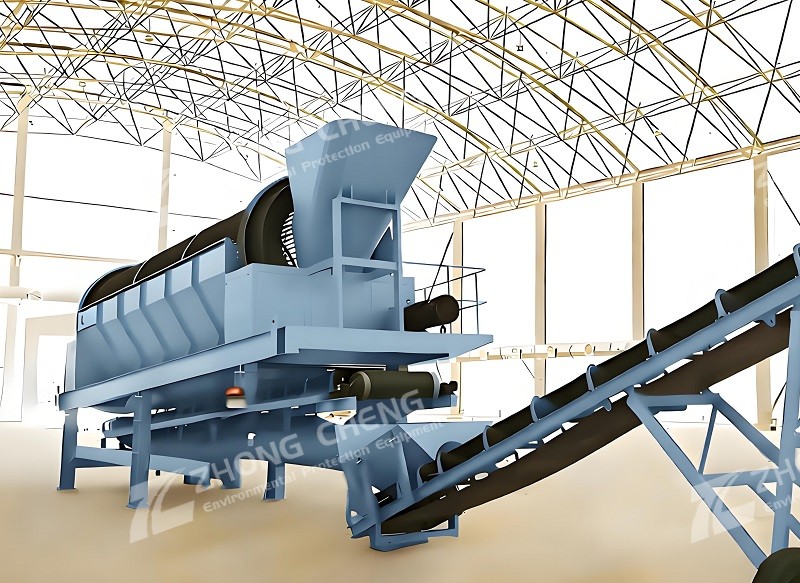

As a core screening equipment in mining, sand and gravel processing, waste treatment, and coal sorting, the performance of the trommel screen directly determines the efficiency, accuracy, and overall cost of material processing. Zhengzhou Zhongcheng Environmental Protection Equipment Co., Ltd. has been deeply involved in the screening equipment field for many years. With its rich industry experience and technological accumulation, the company has launched custom trommel screen that overcome the shortcomings of general-purpose equipment, such as poor adaptability and insufficient efficiency, providing precise screening solutions for customers in different industries. Zhongcheng's custom trommel screen are positioned around the core principles of "on-demand design, superior performance, stable reliability, and controllable costs." Their features and advantages span the entire lifecycle of design, manufacturing, operation, and service, making them the preferred equipment for large-scale production in various industries.

A. Ultimate Customized Design, Precisely Matching Diverse Needs

The core advantage of Zhongcheng's custom trommel screen lies in "customization." The design philosophy is not simply adjusting equipment dimensions, but rather a comprehensive optimization based on the customer's specific working conditions, ensuring a perfect match between the equipment and material characteristics, process requirements, and site conditions.

In terms of material adaptation, Zhongcheng's engineering team first thoroughly analyzes the core parameters of the customer's materials, including particle size distribution, moisture content, viscosity, hardness, and corrosiveness, and then designs the core structure accordingly. For high-humidity and high-viscosity materials (such as river silt, aged waste, and wet coal), the screen structure and anti-clogging device are specifically optimized, using a plate-type automatic screen cleaning mechanism and anti-stick coating to fundamentally solve the problem of screen clogging; for high-hardness and high-abrasion materials (such as granite and iron ore), high-strength wear-resistant steel is used to manufacture the screen drum and key components, providing wear resistance far superior to ordinary steel and significantly extending service life; for fine-grained screening needs, the screen hole shape and arrangement are precisely designed, and high-precision punching technology is used to ensure sufficient screening accuracy to meet fine screening requirements.

In terms of process adaptation, Zhongcheng can provide diverse customization options based on the customer's screening objectives. For multi-stage sorting, a multi-section screening drum can be designed, with different mesh sizes arranged in sections to separate materials into various particle size grades in a single pass, eliminating the need for subsequent secondary screening and significantly improving process efficiency. For scenarios requiring bag breaking and screening, such as waste treatment, specialized bag-breaking tools are added inside the screening drum to achieve integrated "screening + bag breaking" operation, preventing plastic films and other materials from tangling the equipment. For continuous production needs, the inlet and outlet structures of the equipment are optimized for seamless connection with upstream conveying equipment and downstream crushing/sorting equipment, ensuring a smooth workflow for the entire production line.

In terms of site and capacity adaptation, Zhongcheng can flexibly design equipment types and installation methods. For large-scale production scenarios such as large mines and waste treatment plants, large fixed-type trommel screens are customized, featuring an optimized length-to-diameter ratio design for ultra-high processing capacity, meeting the demands of high-intensity continuous operation. For mobile working conditions such as river dredging and on-site construction waste treatment, mobile trommel screens are customized, equipped with wheeled or tracked chassis for flexible relocation without complex installation and commissioning. For customers with limited site space, a compact structure is designed, optimizing the layout of the frame and transmission system to minimize the footprint while ensuring performance, and reserving maintenance space, balancing practicality and convenience.

B. Core Performance Upgrades, Breakthroughs in Screening Efficiency and Accuracy

Based on customization, Zhongcheng trommel screens achieve comprehensive improvements in screening efficiency, accuracy, and stability through structural optimization and technological innovation, with core performance far exceeding general-purpose equipment.

High screening efficiency is a significant feature of Zhongcheng custom trommel screen. They utilize an optimized drum inclination angle design, which can be flexibly adjusted according to actual needs. Combined with precise speed control, this ensures that materials fully tumble and roll inside the drum while maintaining a reasonable forward speed, preventing material stagnation or excessively fast passage. With the internal lifting plate structure, materials are evenly lifted and scattered, ensuring sufficient contact with the screen mesh and effectively improving the fine material screening rate. The automatic screen cleaning mechanism, designed for sticky materials, continuously "combs" the screen mesh through the relative movement of the cleaning components and the screen body during the screening process. Even when processing high-moisture, sticky materials, the screening efficiency remains exceptionally high, far exceeding that of general-purpose equipment.

The screening accuracy is precise and controllable, meeting high-quality production requirements. Zhongcheng's custom trommel screen utilize high-precision screen mesh processing technology, resulting in minimal screen hole size errors. Combined with a reasonable screen tensioning structure, this avoids screening deviations caused by screen deformation. Simultaneously, by optimizing the material's trajectory within the drum, the phenomenon of fine particles being carried away and coarse particles leaking through the screen is reduced, resulting in extremely high grading accuracy. In the sand and gravel processing industry, the sand and gravel processed by Zhongcheng's custom trommel screen have extremely low mud content, fully meeting the industry standards for construction sand; in the coal sorting field, it can accurately separate lump coal from coal powder, improving the calorific value and utilization value of the coal.

High processing capacity and wide applicability meet the needs of different production scales. The processing capacity of Zhongcheng's custom trommel screen can be flexibly adjusted according to customer needs. Small-scale equipment can meet the daily production needs of small and medium-sized workshops, while large-scale equipment can be adapted to the large-scale production of large mines and waste treatment plants. It is suitable for a wide range of material particle sizes; whether fine particles or large lumps, precise screening can be achieved. Whether it's sand and gravel, coal, waste, chemical raw materials, or organic fertilizers, efficient screening can be achieved.

C. Optimized Structural Design, Stable, Reliable, and Easy to Maintain

Zhongcheng's custom trommel screen prioritize both stability and convenience in their structural design. Through detailed optimization, the equipment failure rate and maintenance costs are reduced, ensuring long-term stable operation.

The structure is robust and durable, ensuring stable and trouble-free operation. The equipment frame is made of welded structural steel, and the entire structure undergoes annealing treatment to eliminate stress, ensuring sufficient frame strength and minimal deformation; the drum body adopts an integral through-shaft or shaftless design, and the support structure is optimized according to the material weight and rotation speed. During operation, vibration is low and noise is minimal, allowing for 24-hour continuous operation. The transmission system utilizes top international brands (such as SKF bearings and Siemens reducers) and features a sealed design to effectively prevent dirt, dust, and moisture from entering the interior, reducing the incidence of transmission failures. It is also equipped with an overload protection device; when large foreign objects (such as rebar or large rocks) are mixed in with the material, the equipment can automatically shut down or trigger an alarm, preventing damage to core components.

Maintenance is highly convenient, significantly reducing downtime costs. Zhongcheng's customized trommel screen adopts a split screen design, with the screen fixed by bolts or buckles. Replacement does not require complete disassembly of the equipment and can be completed by a single person, taking significantly less time than with general-purpose equipment. The sealed dust cover has observation windows on both sides, allowing operators to monitor the operating status in real time. Quick-opening access doors are provided at the ends and sides for maintenance, eliminating the need to disassemble the main structure during regular inspections, making it convenient and efficient. Furthermore, the core components of the equipment are highly wear-resistant, and key components such as the screen and drum have a very long service life. Routine maintenance only requires periodic checks of fastening, lubrication, and cleaning of surface debris, resulting in significantly lower maintenance costs compared to general-purpose equipment.

The fully sealed design ensures both environmental protection and operational safety. To address dust pollution, Zhongcheng's customized trommel screen uses a fully sealed dust cover design, completely enclosing the screening drum, effectively preventing dust from flying during the screening process and significantly reducing dust emissions compared to traditional dry screening equipment. Combined with environmental protection equipment such as pulse dust collectors, it can achieve zero dust pollution emissions, fully complying with current environmental policies. The sealed cover also acts as a noise barrier, significantly reducing equipment operating noise and improving the operating environment. In addition, the sealed structure prevents rainwater and debris from entering the equipment, extending the service life of electrical components and the transmission system.

D. Full-cycle service guarantee, controllable costs, and extremely low risk

The advantages of Zhongcheng's customized trommel screen are not only reflected in the equipment itself, but also throughout the entire service cycle, from pre-sales to after-sales, providing customers with a "worry-free, effortless, and cost-effective" cooperation experience.

In the pre-sales stage, Zhongcheng provides professional solution consulting and on-site inspection services. The engineering team goes deep into the customer's production site to gain a detailed understanding of material characteristics, process flow, site conditions, and capacity requirements. They provide free customized screening solutions, including equipment models, structural design, and installation layout, and offer equipment operating cost calculations to help customers optimize their investment plans. They provide one-on-one technical support to address customer questions and can even arrange material testing to allow customers to intuitively understand equipment performance.

During the sales process, standardized manufacturing and precise installation are implemented. Zhongcheng strictly adheres to ISO9001 quality system standards for production, and all core components undergo rigorous testing to ensure equipment quality. Based on customer needs, on-site installation and commissioning services are available, with a professional installation team responsible for equipment positioning, fixing, wiring, and trial operation, ensuring installation accuracy and operational stability. Simultaneously, systematic training is provided to customer operators, covering equipment operation, parameter adjustment, daily maintenance, and troubleshooting, ensuring that customers can quickly get started.

In the after-sales stage, efficient response and comprehensive support are provided. Zhongcheng promises free replacement of faulty parts during the equipment warranty period, provides a 24-hour technical support hotline, and responds quickly to fault reports. They can quickly arrive on-site in nearby areas and within a short time in remote areas, minimizing downtime. Regular customer visits are conducted to understand equipment operation and provide preventive maintenance suggestions. Original factory spare parts are supplied long-term, with transparent pricing and timely delivery, preventing production disruptions due to spare parts shortages. In addition, Zhongcheng can provide equipment upgrade and modification services based on customers' subsequent capacity increase or process adjustment needs, extending equipment lifespan and increasing its added value.

E. Widely Applicable to Multiple Industries, Outstanding Comprehensive Benefits

Zhongcheng's custom trommel screen, with their diverse adaptability, have been widely used in mining, sand and gravel processing, river dredging, construction waste treatment, coal sorting, chemical industry, agriculture, and many other fields, creating significant economic and environmental benefits for customers. In the mining and aggregate industries, its high-efficiency screening capabilities significantly improve the quality of sand and gravel, dramatically increasing the yield of qualified aggregates and greatly enhancing product market competitiveness; in the waste treatment industry, the multi-stage customized trommel screen achieves precise waste classification, laying the foundation for subsequent resource utilization and significantly increasing the waste recycling rate; in the coal industry, it precisely separates lump coal from coal powder, improving the calorific value of coal and reducing transportation and processing costs; in river dredging projects, the mobile customized trommel screen can complete mud and stone separation on-site, allowing the separated sand and gravel to be directly recycled, and the treated soil to be used for riverbank reinforcement, achieving a win-win situation for resource recycling and ecological protection.

Zhongcheng's custom trommel screen, with "ultimate customization, superior performance, stability and reliability, and full-cycle guarantee" as its core advantages, not only solve the pain points of poor adaptability and insufficient efficiency of general-purpose equipment, but also achieve multiple goals of "improved efficiency, reduced costs, and environmental compliance" through structural optimization and service upgrades. Whether it's large-scale production enterprises or small and medium-sized customers, they can obtain the most suitable screening equipment through Zhongcheng's customized solutions. As various industries continue to raise their requirements for screening accuracy and environmental protection, Zhongcheng's custom trommel screen will become the preferred equipment for more customers, providing strong support for the high-quality development of various industries, thanks to its technological advantages and service guarantees.