In the industrial screening equipment market, vibrating screens are key equipment for efficient material separation. Their performance and quality directly impact a company's production efficiency and cost control. ZC Eco's vibrating screens, with their multi-faceted competitive advantages, have become the preferred choice for many customers. The following analyzes the underlying reasons why customers choose ZC Eco vibrating screens, based on six key factors.

A. Precision screening ensures consistent product quality

1. High-frequency vibration technology enables fine grading

The ZC Eco vibrating screen is equipped with a proprietary high-frequency vibration motor, whose vibration frequency can be precisely adjusted based on material characteristics. For materials with minute particle size variations (such as API granules in the pharmaceutical industry and powdered raw materials in the food industry), stable amplitude and frequency control enables precise screening within the 0.075mm-10mm range. Classification accuracy is ≤2%, far below the industry average of 5%. This high precision ensures that the particle size uniformity of customers' finished products meets stringent quality standards, reducing rework losses due to unqualified screening.

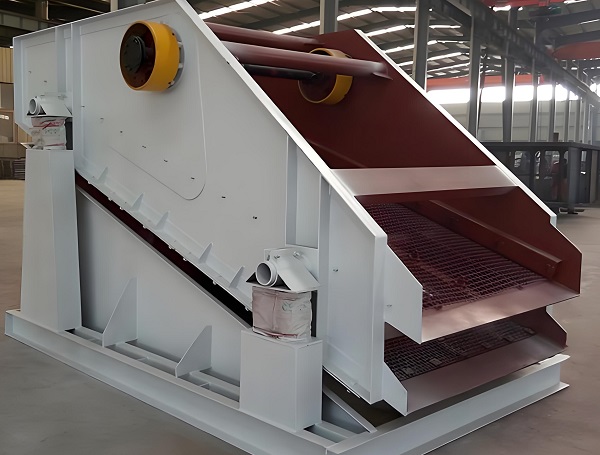

2. Multi-layer screen design improves sorting efficiency

The equipment utilizes a stacked screen structure of 2-5 layers, each layer of which can be configured with a different aperture, allowing for the separation of multiple material grades in a single operation. For example, in the mining industry, traditional single-screen equipment requires batch screening of three particle sizes. The ZC Eco vibrating screen, however, uses three layers of screens operating simultaneously, reducing processing time by 60% while also reducing energy consumption during equipment startup and shutdown. Furthermore, the screens are secured with quick-release clips, reducing replacement time from 40 minutes with traditional equipment to 10 minutes, further minimizing production interruptions.

B. Efficient operation and reduced unit production costs

1. High throughput for large-scale production

For large-scale industrial applications, the ZC Eco vibrating screen offers a processing capacity of 1-100 tons/hour (depending on the model). In construction aggregate production lines, a single 1860 vibrating screen can process over 2,000 tons of sand and gravel per day, meeting the continuous feeding needs of large-scale mixing plants. Compared to conventional equipment of the same specification, unit energy consumption is reduced by 15%-20%.

2. Anti-clogging design reduces downtime for cleaning.

A self-cleaning bouncing ball device is installed on the bottom of the equipment. During vibration, it impacts the screen mesh at high frequencies, effectively removing sticky materials (such as clay and fertilizer particles) adhering to the mesh. Furthermore, the screen mesh is tilted at an adjustable angle of 15°-25°, which, combined with gravity, accelerates material flow and prevents accumulation and blockage. In municipal sludge treatment projects, this design has extended the equipment's continuous operation time to over 8 hours, increasing operating efficiency by 300% compared to the 2-hour cleaning cycle of conventional equipment.

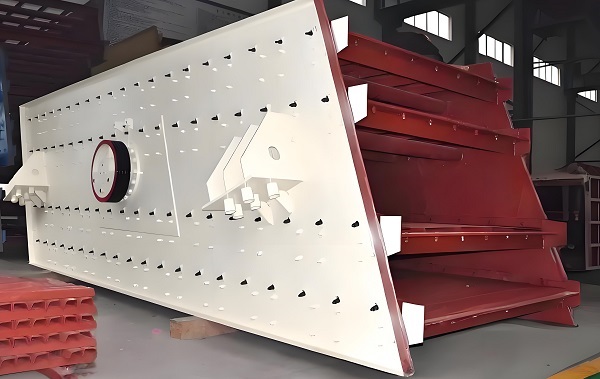

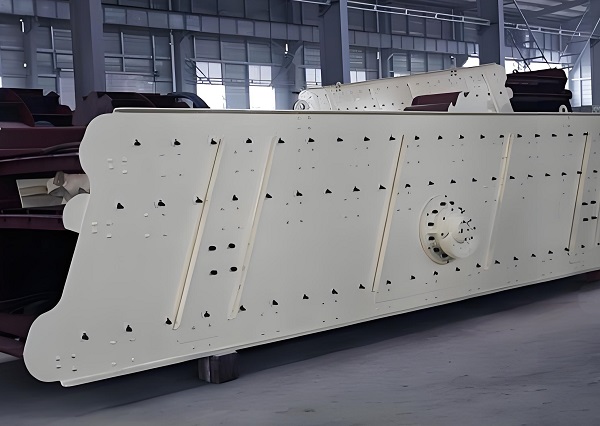

C. Durable and reliable, extending equipment life.

1. High-strength material withstands harsh operating conditions.

The vibrating screen frame is welded from low-alloy, high-strength steel with a compressive strength of 345 MPa, capable of withstanding long-term material impact. The screen mesh is made of high-manganese steel or polyurethane, offering wear resistance 3-5 times that of ordinary carbon steel mesh. In the crushing and screening process of metal mines, the ZC eco vibrating screen boasts an average service life of over five years, 2-3 years longer than similar equipment, reducing equipment replacement frequency and initial investment.

2. Shock-absorbing structure reduces component wear

Highly elastic rubber shock absorbers installed at the ground contact points absorb over 60% of vibration energy, reducing impact on the frame and foundation. Furthermore, a flexible coupling is used to connect the motor and screen body, eliminating component wear caused by rigid transmission. This design reduces the failure rate of key components (such as bearings and motors) by 40%, significantly reducing maintenance frequency and spare part replacement costs.

D. Flexible Adaptability to Meet Diverse Industry Needs

1. Customized Solutions to Adapt to Special Materials

ZC eco offers customized designs based on customer material characteristics (such as moisture, corrosiveness, and temperature). For example, for corrosive materials in the chemical industry, the screen body and mesh are made of 304 stainless steel. For high-temperature materials (such as cement clinker), high-temperature seals and cooling systems are included to ensure stable operation in environments up to 150°C. In the grain processing industry, dust covers and negative pressure exhaust devices can also be installed to prevent dust contamination and comply with food hygiene standards.

2. Modular Combination Adapts to Capacity Changes

The equipment supports multiple units connected in series or parallel, allowing customers to flexibly increase or decrease the number of units based on capacity expansion needs. For example, a small mineral processing plant can initially be equipped with one 1540 vibrating screen. As production capacity increases, two units of the same model can be connected in parallel to double the processing capacity, eliminating the need to replace large equipment and reducing expansion costs. Furthermore, the screen aperture can be adjusted according to production standards to meet the screening requirements of different product batches, enhancing the flexibility of the production line.

E. Intelligent and Convenient, Reducing Operation and Maintenance Management

1. Intelligent Monitoring System Enables Remote Operation and Maintenance

The new vibrating screen features built-in IoT sensors that monitor 12 key parameters, including vibration frequency, motor temperature, and bearing speed, in real time. These parameters are synchronized to the customer's mobile phone or computer via a cloud platform. When parameters exceed safe ranges, the system automatically issues audible and visual alarms and provides notifications with the cause of the problem and recommended solutions. In remote mining projects, customers can promptly detect equipment anomalies through remote monitoring, reducing on-site inspection costs and shortening fault response time to less than 30 minutes.

2. User-friendly Design Simplifies Operation

The touchscreen control panel features five common screening modes (such as fine screening and rapid impurity removal), which operators can activate with a single click without specialized training. The feed inlet is equipped with a flow control valve, which allows real-time control of the feed rate based on material characteristics to prevent overload. Furthermore, the equipment features a maintenance access and observation window for convenient daily inspection and maintenance, further reducing labor costs.

F. Service Guarantee, Relieving Customer Worries

1. Full-Life Cycle Service Covering the Life of the Equipment

zc eco provides a full service lifecycle, from initial selection consultation, mid-term installation and commissioning, to ongoing maintenance. The equipment undergoes 72 hours of continuous operation testing before shipment to ensure performance meets specifications. During the installation phase, technicians are dispatched for on-site guidance to ensure precise integration with the production line. Free spare parts replacement and technical support are provided during the warranty period, and lifetime maintenance services are provided after the warranty period. 2. Rapid Response Mechanism Resolves Unexpected Issues

A 24-hour online customer service hotline and spare parts warehouse ensure next-day delivery of frequently used spare parts, minimizing equipment downtime. This efficient service system ensures worry-free operation for customers.

The ZC Eco vibrating screen, with its guaranteed precision screening, cost-effective operation, durable and reliable performance, flexible adaptability, intelligent and convenient operation, and comprehensive, attentive service support, is an ideal choice for customers across various industries looking to improve production efficiency and reduce operating costs. Whether it's a fine chemical company focused on product quality or a large-scale mine focused on production capacity, the ZC Eco vibrating screen solution will provide the right value for your needs.