In the entire chain of construction waste resource utilization, the trommel screen, with its unique structural design and stable grading performance, has become the core equipment in the waste screening process. Whether it is demolition waste mixed with concrete blocks, brick and tile fragments, or decoration waste containing sand, gravel, and plastic, the trommel screen can accurately separate waste components with different particle sizes and properties through a scientific screening mechanism, providing a foundation for subsequent recycling or harmless disposal. To understand how the trommel screen achieves efficient screening of garbage, it is necessary to analyze from multiple dimensions such as its core working principle, structural composition, workflow, performance regulation, and practical application adaptation, and comprehensively grasp the screening logic and practical value of this equipment.

The core principle of using a trommel screen to screen garbage is to achieve physical separation of materials through the dual action of "rotational motion+aperture classification". Its essence is a mechanical sorting process based on differences in material particle size. Unlike other screening equipment such as fixed screens and vibrating screens, the core working component of a trommel screen is a tilted cylindrical screen cylinder. When the motor drives the screen cylinder to rotate around the axis through the transmission system, the garbage material entering the interior of the screen cylinder will undergo spiral rolling and movement along the axis direction of the screen cylinder under the combined action of gravity, centrifugal force, and friction force of the inner wall of the screen cylinder. During this process, material particles with a particle size smaller than the sieve aperture will continuously fall through the sieve aperture and become "undersized products"; Materials with a particle size larger than the sieve aperture will be transported to the end of the sieve cylinder as it rotates, becoming "screened products" and completing a basic classification screening.

The preparation work before equipment startup is the first line of defense to ensure safe operation, which must be comprehensive and meticulous, without leaving any hidden dangers. Firstly, it is necessary to conduct a site and environmental inspection, clean up the debris and obstacles around the trommel screen, ensure sufficient operating space for the equipment, and especially avoid hard objects such as metal tools and discarded steel bars from approaching the drum area to prevent them from being caught up and causing equipment damage after startup. At the same time, the drainage situation of the work site should be checked. If there is water accumulation on the site, it should be promptly drained to avoid soaking the equipment base or motor, which may cause circuit failure or component corrosion. For mobile trommel screens, it is also necessary to confirm whether the equipment support is stable and whether the hydraulic support legs are fully extended and in contact with the ground to prevent shaking or tipping during operation.

In this process, the synergistic effect of multiple forces is the key to ensuring the screening effect. Gravity provides the fundamental driving force for the axial movement of materials, while the inclination angle of the screening cylinder directly regulates the speed of material movement - the larger the inclination angle, the faster the material moves and the shorter the residence time, making it suitable for scenarios with large processing volumes but low screening accuracy requirements; The smaller the inclination angle, the longer the material residence time, and the more thorough the screening, which is more suitable for high-precision grading requirements. Centrifugal force can enhance the contact frequency between the material and the sieve, especially for garbage materials with strong viscosity. Centrifugal force can promote their full dispersion in the sieve cylinder, avoid particle aggregation and blockage of the sieve holes, and improve screening efficiency. The structure of a scraper (or lifting plate) usually installed on the inner wall of the screening cylinder can further enhance the rolling effect of the material, lift the bottom material to a certain height and let it fall down, so that the material particles are more evenly in contact with the sieve, avoiding blind spots caused by local material accumulation, and ensuring that every particle that meets the conditions can pass through the sieve hole smoothly.

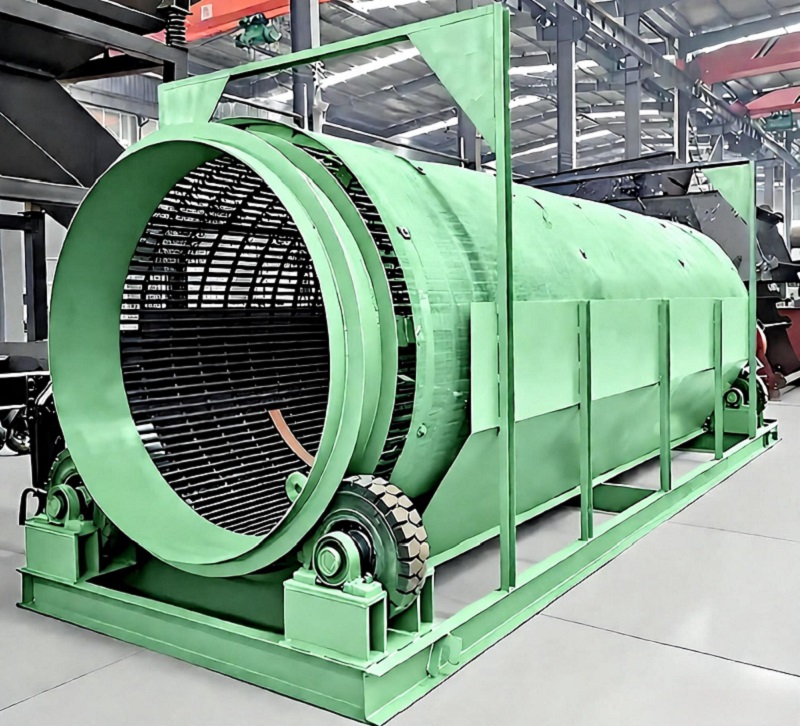

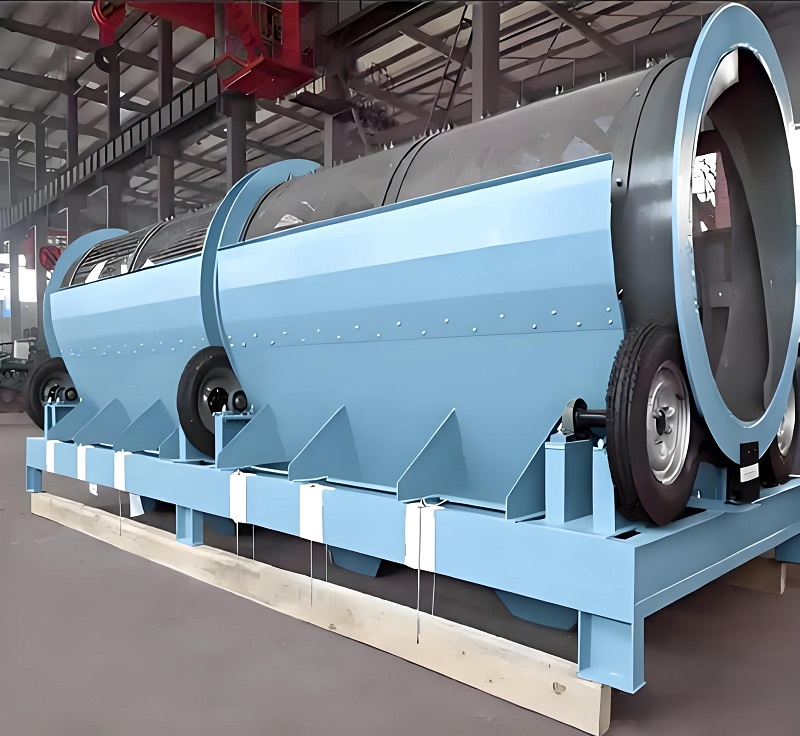

The structural composition of the trommel screen is the hardware foundation for achieving efficient screening. Each component plays a specific role in the screening process, and the various parts work together to form a complete screening system. The core component of the screen cylinder is the key to screening, and its material and screen structure need to be customized according to the characteristics of the waste. For hard concrete blocks and stones in construction waste, the screen is usually made of high-strength materials such as high manganese steel and wear-resistant alloys to prevent the screen from being damaged by impact; The design of the sieve aperture needs to be combined with the screening requirements. A single-stage drum sieve can be set with one aperture to achieve coarse and fine separation, while a multi-stage drum sieve (such as a double-layer or three-layer sieve structure) will be set with screens of different apertures in the same sieve cylinder, gradually increasing the aperture from the inside to the outside, achieving multi-stage classification of garbage. Multiple specifications of products can be obtained in one screening.

The transmission system provides power support for the rotation of the sieve cylinder, and common transmission methods include belt transmission and chain transmission. Belt transmission, with its characteristics of smooth operation, low noise, and good buffering, is suitable for small and medium-sized trommel screens. It can effectively alleviate the vibration caused by the impact of garbage materials and protect the motor and equipment body; Chain drive has the advantages of high transmission efficiency, high torque, and strong load-bearing capacity, making it more suitable for large trommel screens with large processing capacity and heavy load, ensuring that the screen cylinder can maintain a stable speed when processing high hardness and large particle size garbage. The support system consists of a support wheel, a stop wheel, and a base. The support wheel is responsible for supporting the weight of the screen cylinder and assisting its rotation, while the stop wheel prevents the screen cylinder from deviating in the axial direction. The base is connected to the ground through a shock absorber to reduce the impact of equipment vibration on the site during the screening process, while ensuring the overall stability of the equipment.

The feeding and discharging system is responsible for the orderly transportation of materials. The feeding hopper is usually designed with a tilt and equipped with a flow control device, which can control the feeding speed according to the processing capacity of the screening cylinder, avoiding problems such as material accumulation and insufficient screening caused by excessive feeding at once; The discharge section is equipped with independent discharge ports and conveyor belts according to the different destinations of the screened and screened products, ensuring that different specifications of garbage components are collected separately and avoiding secondary mixing. In addition, in response to the problem of dust generation during the screening process of construction waste, modern trommel screening systems are usually equipped with sealing covers and dust removal devices to completely enclose the screening cylinder. The dust generated during the screening process is collected through equipment such as pulse dust collectors, which not only meets environmental requirements but also protects the health of operators.

From the actual operation process, the trommel screen screening of garbage is a complete process of "pretreatment feeding screening classification collection", and the standardized operation of each link directly affects the final screening effect. The preprocessing stage is an important prerequisite for improving screening efficiency. Before entering the trommel screen, construction waste usually needs to undergo preliminary manual sorting or magnetic separation to remove oversized debris (such as discarded furniture and large metal components) and hard objects that may damage the screen mesh (such as steel bars and scrap iron). This step not only prevents large debris from getting stuck in the screening cylinder and avoiding damage to the screen mesh, but also reduces interference during the subsequent screening process, ensuring stable operation of the equipment. For example, when dealing with demolition waste, if steel bars longer than 1 meter are not removed in advance, the steel bars may become entangled inside the sieve cylinder or stuck in the sieve holes, causing equipment shutdown and affecting the progress of the operation.

The feeding process should follow the principle of "uniformity and continuity". The operator uses the adjustment device of the feeding hopper to feed the garbage material into the sieve cylinder at a stable flow rate. The feeding speed should match the processing capacity of the sieve cylinder. If the feeding is too fast, there will be too much material accumulation in the sieve cylinder, which will cause some materials to not fully contact the sieve and be transported to the discharge port, resulting in the mixing of large particles in the screened product and a decrease in screening accuracy; If the feeding is too slow, it will lead to waste of equipment capacity and reduce operational efficiency. Therefore, in practical operation, operators need to dynamically adjust the feeding speed according to the speed, aperture, and material characteristics of the sieve cylinder, to ensure that the appropriate material filling amount is always maintained inside the sieve cylinder.

The screening process is the core of the entire process. When the garbage material enters the rotating screening cylinder, it begins to roll and move under the combined action of gravity, centrifugal force, and the plate. Taking the treatment of decoration waste as an example, smaller components such as fine sand and cement powder in the material will quickly pass through the sieve aperture and fall into the undersized discharge outlet, becoming fine aggregates that can be used for roadbed filling or recycled mortar production; Medium sized components such as brick and tile fragments and small concrete blocks will continue to move within the sieve tube. For trommel screens with a double-layer sieve structure, these materials will pass through the middle sieve and become the second stage product, which can be used to make permeable bricks and other building materials; The concrete blocks and crushed stones with the largest particle size will be discharged from the end of the screening cylinder and enter the subsequent crushing process. After crushing, they will return to the screening system again to achieve the recycling of resources.

During this process, operators need to monitor the screening situation in real time and judge the screening effect by observing the material status at the discharge port. If too many large pieces of material are found in the screened product, it may be due to damage to the sieve mesh, and the machine should be stopped and replaced in a timely manner; If there are a large number of fine particles mixed in the screened product, it may be due to the feed rate being too fast or the screen drum speed being too low, resulting in insufficient material residence time, and the operating parameters need to be adjusted appropriately. The graded collection process uses independent conveyor belts to transport products of different specifications to designated silos, ensuring orderly storage of each component and providing convenience for subsequent resource utilization. For example, the screened fine aggregates can be directly transported to the recycled concrete mixing plant, while the medium particle size aggregates are sent to the brick making workshop, achieving an efficient operation mode of "screening and use".

The screening effect of a trommel screen is not fixed and is influenced by various factors. By scientifically controlling these factors, the optimization of screening efficiency and accuracy can be achieved. The rotation speed of the sieve cylinder is one of the core control parameters. When the rotation speed is too high, the material will tightly adhere to the inner wall of the sieve cylinder and make circular motion under the action of centrifugal force, which cannot effectively roll and move, and the screening efficiency will significantly decrease; When the speed is too low, the material moves slowly, and although the screening is more thorough, the production capacity will be limited. Therefore, it is necessary to determine the appropriate speed range based on the particle size and density of the material - for materials with smaller particle size and higher density, the speed can be appropriately increased to enhance the contact frequency between the material and the sieve; For materials with larger particle size and lower density, it is necessary to reduce the rotational speed to ensure that the material has sufficient residence time to complete screening.

The aperture and opening rate of the sieve directly determine the screening accuracy and processing capacity. The selection of aperture should be based on the screening target. If fine aggregates need to be obtained, a small aperture sieve should be used. If only large impurities need to be removed, a large aperture sieve can be used; The aperture ratio refers to the ratio of the screen area to the surface area of the screen cylinder. The higher the aperture ratio, the greater the probability of material passing through the screen and the stronger the processing capacity. However, a too high aperture ratio will reduce the strength of the screen and shorten its service life. Therefore, a balance needs to be sought between processing capacity and durability of the screen. The physical properties of materials can also affect the screening effect. Garbage materials with high moisture content are prone to particle agglomeration, causing fine particles to adhere to the surface of large materials or block the sieve holes. In this case, it is necessary to increase the number of plates, increase the speed of the sieve cylinder, or use auxiliary measures such as heating and drying to improve the screening efficiency; The hardness and abrasion of the material determine the service life of the sieve. When dealing with high hardness construction waste, it is necessary to choose a sieve material with stronger wear resistance to reduce the frequency of replacement.

With the continuous improvement of the demand for the resource utilization of construction waste, the screening technology of trommel screens is also constantly upgrading, and various specialized types suitable for different scenarios have emerged, further expanding their application scope. Mobile trommel screen is one of the mainstream development directions in recent years. It integrates the screen cylinder, motor, conveyor belt, dust removal device and other components on a movable chassis, equipped with hydraulic support legs and traction devices, which can flexibly transfer according to the location of the garbage generation site, achieving "nearby screening and on-site utilization". This type of trommel screen is particularly suitable for decentralized waste disposal scenarios such as demolition sites and road construction, which can effectively reduce the cost and secondary pollution during waste transportation and improve resource utilization efficiency.

Multi stage trommel screen achieves multi-stage classification of garbage by setting multiple screening cylinders or screen layers with different apertures in the same equipment. It can separate 3-5 different specifications of materials in one operation, greatly improving screening efficiency and product added value. For example, in large-scale construction waste resource utilization bases, multi-stage trommel screens can directly separate waste into multiple components such as fine sand, medium aggregate, coarse aggregate, and large impurities, and connect them to different recycling production lines to form an integrated process of "screening processing application". In addition, the development of intelligent trommel screens has provided new technological support for the screening process. By installing sensors and intelligent control systems on the equipment, key parameters such as screen drum speed, feed rate, and bearing temperature can be monitored in real time. Through big data analysis, automatic adjustment of operating parameters can be achieved. At the same time, it has a fault warning function, which can timely detect equipment abnormalities and notify operators to handle them, reduce downtime, and improve the stability of equipment operation.

In practical applications, the screening effect of the trommel screen is closely related to the daily maintenance of the equipment. As a core vulnerable component, the sieve needs to be regularly inspected for its integrity. If the sieve holes are found to be blocked, high-pressure water flushing or manual cleaning should be used in a timely manner to clear them; If the sieve is damaged, it should be replaced in a timely manner to avoid mixing materials of different specifications. Lubrication of the transmission system is also crucial, and it is necessary to regularly replenish lubricating oil for components such as bearings and gears to ensure smooth transmission and reduce wear; At the same time, the tightness of the belt or chain should be checked, and aged or damaged transmission components should be adjusted or replaced in a timely manner to prevent transmission failures from affecting the rotation of the screen cylinder. In addition, the sealing performance of the equipment also needs to be regularly checked to ensure that the sealing cover is intact, prevent dust leakage, and meet environmental protection requirements.

From the perspective of industry development, the technology of trommel screening garbage is moving towards the direction of "high efficiency, precision, environmental protection, and intelligence". In the future, with the advancement of materials science, more wear-resistant and lightweight screen materials will continue to emerge, further improving the service life and screening efficiency of equipment; The application of intelligent control systems will be further deepened. By combining artificial intelligence algorithms, adaptive optimization of screening parameters will be achieved, and the operating mode will be automatically adjusted according to the characteristics of different waste components to achieve the best screening effect; At the same time, the collaborative integration of trommel screens with other sorting equipment (such as wind separators, magnetic separators, and intelligent recognition sorting devices) will be more closely integrated, forming a multi-dimensional garbage sorting system. It can not only achieve particle size classification, but also combine the density, magnetism, material and other characteristics of materials for precise sorting, providing technical support for the refined resource utilization of construction waste.

Professional training for operators is the foundation for ensuring the standardized use of equipment. Enterprises need to regularly organize technical training for operators, including equipment working principles, operating procedures, precautions, and fault diagnosis methods, to ensure that operators are familiar with equipment performance and can quickly handle common problems. At the same time, it is necessary to establish a strict job responsibility system, clarify the responsibilities of operators, link equipment maintenance with personal performance, and improve the sense of responsibility of operators. In addition, regular safety training should be organized to strengthen the safety awareness of operators, ensure strict compliance with safety operating procedures, and avoid the occurrence of safety accidents.

The trommel screen for garbage screening is an efficient classification process based on physical principles, relying on precision structures, and achieved through standardized processes. The core lies in utilizing the mechanical effect generated by the rotation of the sieve cylinder, combined with different aperture screens, to separate garbage materials according to particle size. Reasonable structural design, scientific parameter regulation, standardized operating procedures, and a sound maintenance system are the key to ensuring the screening effect. In the context of the resource utilization of construction waste, the trommel screen, with its stable and reliable screening performance, has become an important link between waste collection and recycling. The continuous upgrading of its screening technology will also provide solid equipment guarantee and technical support for promoting the construction of "waste free cities" and realizing the development of circular economy. From both technical principles and practical applications, trommel screens play an irreplaceable role in the field of waste treatment. The scientific and practical nature of their screening mechanism makes them one of the core equipment in construction waste resource utilization projects.