In various fields such as mining, construction, river dredging, and waste treatment, the separation and processing of soil-rock mixtures is a crucial prerequisite for ensuring smooth subsequent production processes and improving resource utilization efficiency. Soil-rock separators, as core equipment specifically designed for separating soil and sand, achieve efficient separation of soil and sand by precisely distinguishing the physical characteristics of materials such as particle size and density. This lays the foundation for the recycling and reuse of sand and gravel resources and the harmless treatment of soil. Its performance directly affects the efficiency, cost, and resource recovery quality of material processing. This article will combine the application scenarios of soil-rock separators to elaborate on their core functions and significant characteristics, providing technical reference for equipment sele

A. Core Functions of Soil-Rock Separators

The core function of a soil-rock separator is to achieve precise separation of soil and sand, extending to multiple values such as resource recovery, quality improvement, efficiency enhancement, and environmental protection. This is specifically reflected in the following key scenarios:

1. Mining and Sand and Gravel Processing: Improving Sand and Gravel Quality and Ensuring Subsequent Production

In the mining and sand and gravel processing industries, the extracted raw ore is often a mixture of soil and rock, and the soil, dust, and other impurities contained therein seriously affect the quality of the sand and gravel. The primary function of a soil-rock separator is to remove soil, dust, and fine impurities from the sand and gravel, improving the purity and gradation quality of the sand and gravel. For example, after the extraction of granite, limestone, and other rocks, the soil mixed in the raw ore will adhere to the surface of the sand and gravel. If directly used for concrete mixing, it will reduce the strength and durability of the concrete. Through the separation process of the soil-rock separator, the soil on the surface of the sand and gravel can be completely stripped and separated, reducing the soil content of the sand and gravel to below industry standards (usually requiring the soil content of construction sand not to exceed 3%). At the same time, the separator can classify sand and gravel of different particle sizes according to the sand and gravel particle size requirements, providing qualified raw materials for subsequent crushing and screening processes, reducing repeated processing, and improving overall production efficiency. In addition, the separated pure sand and gravel can be directly used as construction aggregates, road paving materials, etc., significantly increasing their economic value. 2. River Dredging and Water Conservancy Projects: Clearing River Channels and Recovering Resources

After long-term operation, rivers, reservoirs, and other water bodies accumulate a large amount of silt mixed with sediment, which not only blocks river channels and affects flood control safety but also damages the aquatic ecological environment. Sediment separators play an irreplaceable role in river dredging projects. Their core function is to separate soil and sand/gravel from the dredged material. The mixture of mud and sediment excavated by the dredging vessel is transported to the separator via conveying equipment. The sand and gravel are separated and recovered, while the soil is treated to meet discharge standards or used for riverbank reinforcement and land reclamation. On the one hand, the separated sand and gravel can be used as raw materials for water conservancy projects, reducing the cost of purchasing sand and gravel and achieving resource recycling; on the other hand, the separated soil has a lower water content, making it easier to transport and process, avoiding secondary pollution caused by indiscriminate dumping, and effectively clearing river channels to ensure flood control and navigation safety. For example, in small and medium-sized river dredging projects, mobile sediment separators can complete the separation of mud and sediment on-site, significantly shortening the processing cycle and reducing transportation costs.

3. Building Demolition and Construction Waste Treatment: Resource Utilization and Practicing Environmental Protection Concepts

Construction waste generated during building demolition contains a large amount of hard materials such as concrete blocks and brick fragments, mixed with impurities such as soil and wood chips. The role of the sediment separator in this scenario is to separate the soil from the recyclable sand, gravel, and concrete particles in the construction waste. Through separation and treatment, the construction waste particles, after removing soil impurities, can be crushed and screened to produce recycled aggregates, which can be used to produce recycled concrete, permeable bricks, and other building materials; the separated soil can be used for site backfilling and vegetation planting. This process not only achieves the reduction and resource utilization of construction waste, reducing landfill volume, but also reduces reliance on virgin sand and gravel resources, meeting the requirements of green building and environmental protection development. For example, at large demolition sites, a fixed sediment separator, combined with crushing and screening equipment, forms a construction waste treatment production line, enabling on-site treatment and recycling of construction waste, significantly improving processing efficiency. 4. Agriculture and Land Reclamation: Improving Soil and Enhancing Land Utilization

In agricultural production and land reclamation projects, some land is unsuitable for crop growth due to high sand and gravel content (such as Gobi deserts and mountainous wasteland), or because of soil compaction and excessive stone content, which affects farming efficiency. A soil and stone separator can be used to separate sand and gravel from soil, achieving "stone removal and soil retention" or "soil removal and stone retention" depending on the specific needs. In land improvement, by separating and removing large pieces of sand and gravel from the soil, retaining the fine soil, and combining it with organic fertilizers and other soil conditioners, wasteland can be transformed into arable farmland. In saline-alkali land treatment, the separated sand and gravel can be used to lay drainage pipes, improving soil drainage performance and enhancing the effectiveness of soil improvement. Furthermore, in landscape construction, the soil and stone separator can separate sand and gravel of different particle sizes for laying garden paths and creating landscape features, while the separated soil can be used for planting vegetation, achieving rational resource allocation.

5. Coal and Mineral Processing: Assisting in Impurity Removal and Ensuring Production Safety

In coal mining and mineral processing, raw materials are often mixed with impurities such as soil and shale. These impurities not only reduce the quality of coal and ore but also wear down equipment during subsequent crushing and transportation, increasing maintenance costs. The soil and stone separator can be used as a pre-treatment impurity removal device to separate soil and some fine-grained impurities from the raw materials, improving raw material purity. For example, after coal mining, the soil mixed in the raw coal affects the calorific value of the coal. By separating and removing the soil with a soil and stone separator, the coal quality can be improved and transportation costs reduced. In iron ore processing, the separated soil prevents clogging of the screen holes in the screening equipment, ensuring the smooth operation of subsequent beneficiation processes. At the same time, the separation process reduces wear and tear on equipment, extending the service life of crushing and screening equipment, and reducing production safety hazards.

B. Salient Features of Mud and Stone Separators

Combining the needs of different application scenarios, mud and stone separators have developed unique advantages in structural design, performance, and operation and maintenance. Their salient features are mainly reflected in the following aspects:

1. High Separation Efficiency and Large Processing Capacity

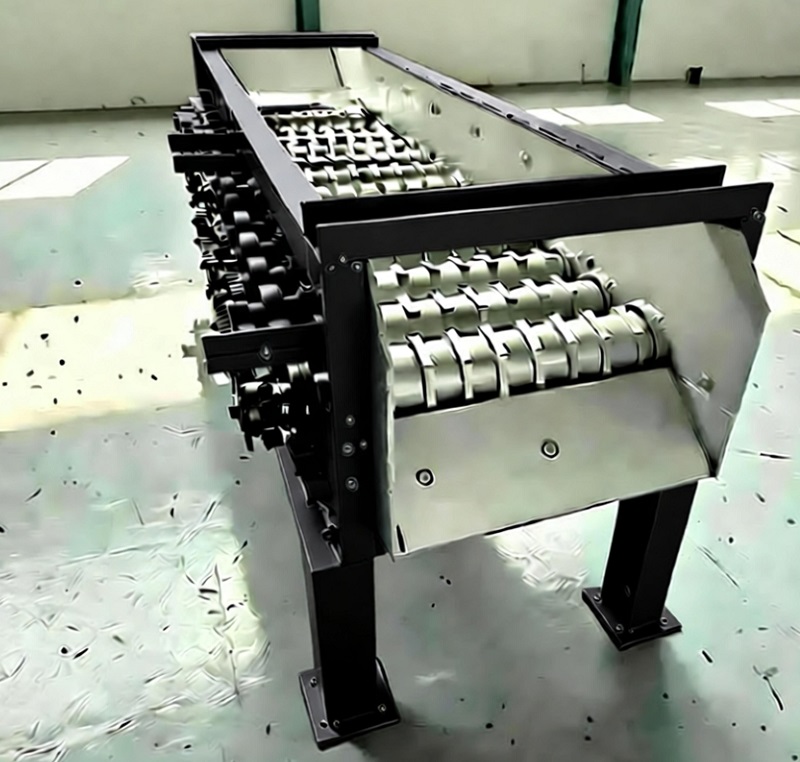

Mud and stone separators utilize targeted separation structures (such as roller type, vibrating type, and spiral type) to achieve rapid separation of mud and sand/gravel. Taking the widely used roller-type mud and stone separator as an example, the equipment uses multiple sets of parallel rotating rollers to achieve graded separation through the gaps between the rollers. Sand and gravel fall through the gaps, while the mud is transported to the discharge port by the rotating rollers. The separation efficiency can reach over 90%. At the same time, the processing capacity of the equipment can be adjusted according to actual needs. Small mobile equipment can process tens of tons per day, suitable for small and medium-sized projects; large fixed equipment can process thousands of tons per day, meeting the large-scale production needs of mines and large-scale dredging projects. The high separation efficiency and large processing capacity significantly shorten the material processing cycle and improve overall production efficiency.

2. Strong Adaptability and Wide Range of Applications

Mud and stone separators can adapt to different types, humidities, and particle sizes of mud and stone mixtures. Whether it's dry mine ore, wet river silt, or highly viscous construction waste, effective separation can be achieved. The equipment can adjust parameters such as roller gap, vibration frequency, and screw rotation speed to adapt to the separation needs of different particle sizes of sand and gravel, with a separation particle size range from a few millimeters to tens of centimeters. At the same time, the equipment can be designed into various types, such as fixed, mobile, and semi-mobile, according to the needs of the application scenario: fixed equipment is suitable for large production lines and can operate continuously for a long time after stable installation; mobile equipment is equipped with wheels or crawler chassis and can be flexibly moved to the work site, especially suitable for highly mobile projects such as river dredging and construction waste treatment; semi-mobile equipment can be disassembled and transported, making it easy to install and use in mines with complex terrain. In addition, the equipment material can be selected according to the material characteristics. For highly corrosive materials, stainless steel can be used; for scenarios requiring high wear resistance, wear-resistant liners can be added to key components to further enhance the adaptability of the equipment.

3. Reasonable Structure, Stable and Reliable Operation

The core components of the mud and stone separator (such as rollers, vibrating screens, and spiral blades) are made of high-strength steel and reinforced through heat treatment, possessing excellent wear resistance and impact resistance, capable of withstanding the impact and abrasion of large pieces of sand and stone. The equipment's transmission system adopts a sealed design to prevent soil and dust from entering and causing malfunctions. It is also equipped with an overload protection device; when large foreign objects (such as rebar or large rocks) are mixed in the material, the equipment can automatically shut down or alarm, preventing component damage. For example, the rollers of the roller-type mud and stone separator are made of seamless steel pipes with wear-resistant surface treatment, and their service life can reach tens of thousands of hours; the vibrating mud and stone separator uses an eccentric block vibration mechanism, ensuring stable operation and adjustable vibration frequency, preventing equipment damage due to uneven vibration. The reasonable structural design and reliable component quality ensure that the equipment can operate stably for a long time under harsh working conditions with a low failure rate.

4. Low Energy Consumption and Operating Costs

The mud and stone separator adopts an optimized power transmission structure, resulting in low power loss and low energy consumption. Compared with traditional water-washing separation equipment, the mud and stone separator does not require a large amount of water resources, saving water costs and avoiding the wastewater pollution problems generated during the water washing process, thus reducing wastewater treatment costs. Taking the roller-type mud and stone separator as an example, the power of a single unit is usually between 10-50kW, adjusted according to the processing capacity. The energy consumption per unit of material processed is only 1/3-1/2 of that of water-washing equipment. At the same time, the maintenance cost of the equipment is low; core components can be replaced individually after wear, without the need for complete disassembly; daily maintenance only requires regular inspection of component tightness, adding lubricating oil, and cleaning debris from the equipment surface. The maintenance process is simple and does not require professional technicians. In addition, the separated sand, gravel, and soil can be directly recycled, creating additional economic benefits and further reducing overall operating costs.

5. Simple Operation and High Degree of Automation

Modern mud and stone separators are generally equipped with intelligent control systems, making operation simple and enabling automated and intelligent operation. The equipment is equipped with a touchscreen control panel, allowing operators to adjust separation parameters (such as roller gap, vibration frequency, and conveying speed) and monitor the equipment's operating status in real time (such as motor temperature, operating speed, and fault alarms). For large-scale production lines, the equipment can be linked with upstream conveying equipment and downstream crushing equipment, automatically adjusting operating parameters based on material flow without manual intervention. For example, in a construction waste treatment production line, the mud and stone separator can automatically adjust the roller speed according to the feeding speed of the belt conveyor, ensuring that the separation efficiency matches the feeding speed; when the equipment malfunctions, the control system can automatically shut down and issue an alarm signal, while recording fault information for quick troubleshooting by staff. Automated control not only reduces manual labor but also improves operational stability and accuracy.

6. Green and environmentally friendly, compliant with policy requirements

The mud and stone separator produces no wastewater or exhaust gas during operation, only a small amount of dust. By equipping it with dust removal equipment (such as a pulse dust collector), effective dust control can be achieved, meeting environmental protection policy requirements. Compared with traditional dry separation equipment, its dust emissions can be reduced by more than 80%; compared with water-washing equipment, it saves a large amount of water resources and avoids environmental problems such as sewage overflow and soil erosion. In environmental protection projects such as river dredging and construction waste treatment, the application of the mud and stone separator can achieve resource utilization of materials, reduce landfill volume, and minimize damage to the ecological environment. For example, in river dredging projects, the separated soil can be used for river embankment reinforcement after solidification treatment, avoiding soil pollution caused by indiscriminate dumping; the separated sand and gravel can be recycled and reused, reducing the exploitation of natural sand and gravel resources, in line with the concept of green development.

As a key piece of equipment in the field of material separation, the mud and stone separator plays a core role in resource recovery, quality improvement, and environmental protection, widely meeting the needs of various industries such as mining, water conservancy, construction, and agriculture. Its high efficiency, stability, energy saving, and environmental protection characteristics make it an ideal equipment for improving material processing efficiency, reducing operating costs, and practicing environmental protection concepts. With continuous technological upgrades, the mud and stone separator will develop towards greater intelligence, larger scale, and multi-functionality, further expanding its application scenarios and providing strong support for the high-quality development of various industries. In practical applications, it is necessary to select the appropriate equipment type and parameters based on the specific material characteristics and processing requirements to ensure that the equipment functions effectively and achieves a balance between economic and environmental benefits.