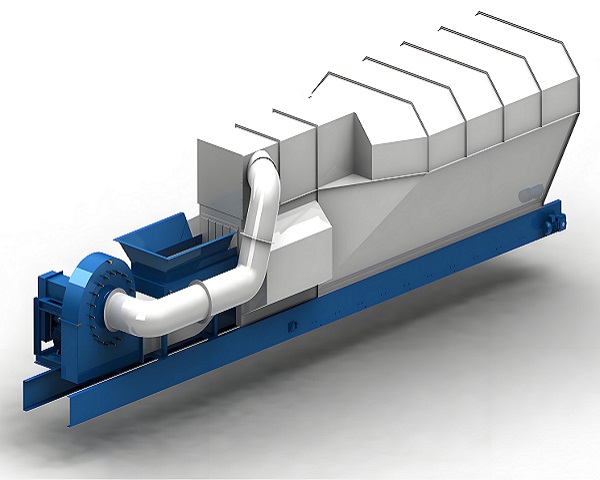

Air classifiers are used for separating light and heavy components, removing impurities, and purifying resources, covering sorting needs in multiple fields. Their non-contact sorting, adjustable parameters, and compact structure solve many pain points of traditional equipment, and have the advantages of high efficiency and environmental protection.

As a key equipment in the field of material sorting, the air separator uses the principles of airflow dynamics to separate light and heavy materials. It has evolved from an early simple air duct equipment to a core tool supporting the upgrading of multiple industries.

Wind sifter, as a sorting device based on aerodynamic principles, play a central role in the entire waste management process, from pretreatment to resource recovery to waste reduction, thanks to their efficient ability to separate materials of varying densities and particle sizes.

When purchasing a hammer crusher, you need to consider your own production needs and comprehensively consider multiple factors such as equipment parameters, material performance, manufacturer strength, and after-sales service to ensure that the equipment you choose can not only meet your current production needs but also have the potential for long-term stable operation.

Hammer crushers are widely used in multiple industrial fields, providing key support for large-scale production and efficient resource utilization in various industries. They are classic equipment in the field of industrial crushing that combines practicality and economy.

In the future, three-dimensional compound crushers will continue to play a core role in the fields of construction waste resource utilization, comprehensive mining processing, solid waste reduction, etc., becoming a key force in promoting the transformation of the industrial crushing industry and providing important support for various industries to achieve efficient resource utilization and susta...

In heavy industries such as mining, construction and building materials, metallurgy and chemical industry, material crushing is the "first checkpoint" in the production process. Its efficiency and crushing quality directly determine the smoothness of subsequent processes and the value of the final product.

The fine crusher eliminates screening obstacles through its crushing function, improves resource recovery efficiency, reduces the cost of the entire chain, and ultimately promotes the transformation of waste management to a "circular economy".

The unique characteristics of industrial waste treatment systems stem from the unique and high-risk nature of the waste they treat. Achieving the goals of "harmless disposal, volume reduction, and resource utilization" requires a coordinated approach of classified disposal, specialized technology, weather-resistant equipment, strict supervision, and standardized management.

Sieving domestic waste is a critical link between waste collection and final disposal. Its operational compliance directly impacts subsequent resource recovery efficiency and environmental compliance.