Wind sifter, as a sorting device based on aerodynamic principles, play a central role in the entire waste management process, from pretreatment to resource recovery to waste reduction, thanks to their efficient ability to separate materials of varying densities and particle sizes. In the treatment of various solid waste types, including household waste, construction waste, and electronic waste, wind sifter precisely separate light and heavy components, laying the foundation for subsequent incineration, landfilling, and recycling, making them an indispensable key piece of equipment in modern waste management systems.

Core Working Principle and Technical Classification of wind sifter

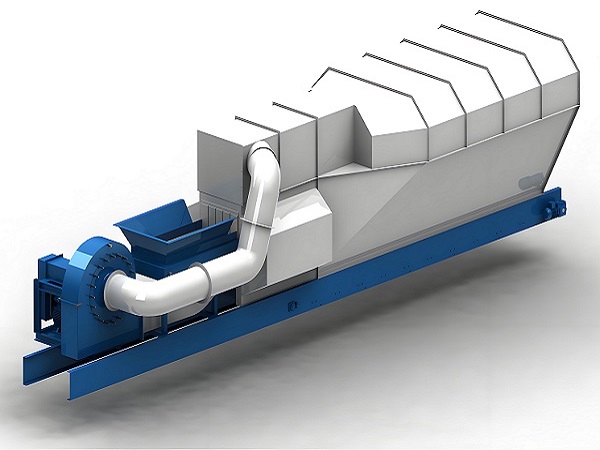

The core principle of wind sifter is to separate materials by exploiting the balance between air resistance and gravity in an airflow. Light materials with low density and large surface area (such as plastics and paper) are carried by the airflow to a distant location for collection, while heavy materials with high density and small surface area (such as metals and masonry) slide down the bottom of the device due to insufficient buoyancy to overcome gravity. Commonly used wind sifter for waste sorting are divided into three main categories based on airflow direction and equipment structure:

Horizontal wind sifter: Airflow is blown horizontally, causing the material to fall evenly from the feed inlet. Light components are carried by the horizontal airflow into the separation chamber, while heavy components settle directly. Their advantages lie in their simple structure and high processing capacity, making them suitable for the initial sorting of large-scale household waste. However, their disadvantage is that separation accuracy is significantly affected by the uniformity of the feed.

Vertical wind sifter (updraft wind sifter): Airflow moves vertically upward, causing the material to fall from the top of the device, encountering the rising airflow in the opposite direction. By adjusting the airflow speed, the separation threshold for materials of different densities can be precisely controlled, resulting in higher separation accuracy than horizontal wind sifter. They are commonly used for the fine sorting of lightweight recyclables such as plastics and paper.

Cyclone wind sifter: Combining the centrifugal force generated by the rotating airflow with the action of gravity, the material enters the device and is spun at high speed by the airflow. The heavy components settle against the wall under the centrifugal force, while the light components are collected in the cyclone separator. This equipment offers high separation efficiency and a small footprint, making it suitable for processing smaller mixed waste components, such as separating light impurities from dehydrated kitchen waste.

Specific Applications in Various Waste Treatment Scenarios

1. Domestic Waste Sorting: Achieving "Light Material Recovery + Heavy Material Volume Reduction"

Domestic waste is complex, containing dozens of components such as plastics, paper, kitchen waste, bricks, and metals. The air separator is the first sorting checkpoint in pre-processing, performing two core tasks:

Light Recyclable Material Purification: After bag breaking and magnetic separation to remove metals, domestic waste enters the air separation system. The horizontal air separator first separates the majority of light materials (such as plastic bags and waste paper), which are then further purified by the vertical air separator. Adjusting the airflow speed to 12-18 m/s, it can separate plastics with a density of approximately 0.9-1.2 g/cm³ from denser paper, increasing the plastic purity from an initial 40%-50% to over 85%, meeting the requirements for recycled raw materials. Many waste incineration plants in my country use a "magnetic separation + two-stage air separation" process, recovering dozens of tons of plastic and paper daily from thousands of tons of domestic waste, achieving resource recycling.

Pretreatment of incineration and landfill materials: Air separation separates lightweight components (such as heavily contaminated plastic film) from heavier components (such as bricks, stone, and glass) that have no recycling value and can be transported separately to the incineration system. The light components have high combustion efficiency and low ash content, effectively improving the thermal efficiency of the incinerator. Heavy components, separated by air separation, are directly landfilled, reducing grate wear and lowering equipment maintenance costs. Data from a waste treatment plant in a coastal city showed that the addition of an air separation process reduced annual incinerator maintenance costs by 30% and increased thermal efficiency by 5%.

2. Construction Waste Sorting: Assisting in the "Resource Utilization of Solid Waste"

Construction waste includes components such as waste concrete blocks, waste bricks, wood chips, and plastic film. wind sifter are primarily used to separate lightweight impurities from heavy aggregates in their resource utilization.

In a construction waste recycled aggregate production line, the crushed material is first graded by a vibrating screen before entering the air separator. Because the density of waste concrete and bricks (2.3-2.8 g/cm³) is much higher than that of wood chips and plastic (0.3-1.5 g/cm³), the airflow easily separates the lightweight impurities, resulting in a heavy aggregate purity exceeding 95%. These purified aggregates can be directly used in the production of recycled concrete, permeable bricks, and other building materials, while the separated lightweight impurities can be further sorted for recycling or incineration. For example, a construction waste treatment plant in Beijing uses a cyclone air separator, which can process 80 tons of crushed material per hour and produce 60 tons of recycled aggregate per day, reducing the amount of construction waste landfilled by over 200,000 tons annually.

3. E-waste Sorting: Precise Recovery of Precious Metal Carriers

E-waste (such as used circuit boards and battery casings) contains lightweight components like plastics and resins, as well as heavier components like metal substrates with precious metals attached. wind sifter are key equipment for "plastic-metal separation":

After low-temperature crushing (to prevent softening and sticking of the plastic), the e-waste is reduced to a particle size of 2-10mm before entering a vertical air separator. By precisely adjusting the updraft velocity (typically 8-12m/s), the lighter plastic particles are carried and collected, while the denser metal particles (including copper, gold, and silver) settle and separate. The separated plastics can be directly recycled and pelletized, while the metal particles are subsequently processed for hydrometallurgical extraction of precious metals. One e-waste recycling company uses a "crushing + air separation + magnetic separation" process, achieving a plastic recovery rate of 92% and tripling the metal enrichment, significantly reducing the cost of subsequent precious metal extraction.

4. Food Waste Processing: Removing Lightweight Impurities

Food waste often contains lightweight impurities such as plastic bags, plastic wrap, and toothpicks. These impurities can entangle processing equipment and affect anaerobic fermentation efficiency. wind sifter effectively address this issue:

After being shredded and dehydrated, the food waste enters the horizontal air separator. Airflow blows plastic impurities with a density of less than 1g/cm³ into a collection bag, while food waste with a high moisture content and density is transported along the bottom to the fermentation system. Data from one food waste treatment plant shows that the air separation process removes over 90% of plastic impurities, increasing subsequent anaerobic fermentation gas production by 12% while reducing equipment downtime due to impurity entanglement.

Core Advantages and Development Directions of wind sifter in Waste Sorting

1. Core Application Advantages

Strong Adaptability: It can process a wide range of waste fractions with particle sizes ranging from 0.5-50mm and density differences exceeding 0.2g/cm³. It is not significantly affected by material moisture (≤30%), meeting the needs of various sorting scenarios. Green and Efficient: Using air as the separation medium, it eliminates the need for chemicals and produces zero secondary pollution. It can process 10-100 tons/hour, with a separation efficiency generally exceeding 85%, and consumes only one-fifth the energy of wet sorting.

Cost Controllable: The equipment offers low manufacturing costs, a small footprint, and is easily integrated with other equipment such as magnetic separation, screening, and crushing to form a production line. Maintenance only requires regular cleaning of the airflow path, resulting in low operating costs.

2. Technological Development Directions

With the increasing demand for refined and resource-efficient waste treatment, wind sifter are evolving towards "intelligent control + collaborative sorting." Firstly, these systems utilize sensors to monitor material flow and density in real time, automatically adjusting airflow speed to dynamically optimize separation accuracy. Secondly, they integrate AI visual recognition technology to further classify lightweight materials (such as PET and PP plastics) after air separation, increasing their recycling value. Furthermore, new equipment, such as "anti-clogging air separation structures" for high-humidity waste and "high-efficiency cyclone separation systems" for fine particles, are emerging, further expanding the application of wind sifter in waste sorting.

With their unique separation principles and flexible adaptability, wind sifter have become the "sorting hub" of various waste treatment systems. Driven by the "dual carbon" goals and policies to recycle solid waste into resources, wind sifter not only help achieve "reduction and harmlessness" in waste treatment, but also play an irreplaceable role in resource recovery and energy consumption reduction, providing key technical support for the development of a circular economy.