Hammer crushers are core equipment for processing medium- and low-hardness materials in industrial production. Their selection and procurement directly impact subsequent production efficiency, operating costs, and product quality. However, the market is flooded with hammer crusher models and manufacturers with varying qualifications. Blindly purchasing a hammer crusher can easily lead to problems such as equipment capacity mismatch, frequent wear and tear, and high maintenance costs. Therefore, when purchasing a hammer crusher, it's important to consider your own production needs and comprehensively consider multiple factors, including equipment specifications, material properties, manufacturer capabilities, and after-sales service. This ensures that the equipment you choose not only meets your current production needs but also offers the potential for long-term stable operation. The following details the key considerations for purchasing a hammer crusher from six core perspectives.

Clarify Your Production Needs: Accurately Match Equipment Targeting

The primary prerequisite for purchasing a hammer crusher is to clearly define your needs. Blindly pursuing "high capacity" and "high configuration" without considering the actual production scenario can easily lead to idle equipment or wasted production capacity. Conversely, insufficient equipment capacity can hinder overall production progress. The following three requirements should be clearly defined:

1. Material Characteristics: Determines Core Equipment Configuration

Material characteristics are a key factor influencing equipment selection. A detailed understanding of the material's hardness, moisture content, particle size, and composition is crucial:

Hardness: Hammer crushers are suitable for medium-to-low-hardness materials with a Mohs hardness of 6 or less (such as limestone, coal, and gypsum). Materials with a hardness exceeding 7 (such as granite and iron ore) can easily wear the hammers (possibly reducing their lifespan from 3 months to 1 month) and reduce crushing efficiency. In this case, a heavy-duty hammer crusher or a different type of equipment (such as a cone crusher) should be selected.

Moisture Content: High material moisture content (>20%) can easily cause wall sticking and clogging. A machine with an anti-stick liner and vibrating grates should be selected to prevent material accumulation in the crushing chamber, leading to equipment downtime. If the material is dry (moisture content <5%), attention should be paid to the equipment's dust removal system to prevent dust contamination.

Particle Size: The maximum particle size of the raw material and the particle size requirements for the crushed product should be clearly defined. If the raw material particle size exceeds 7, the crushing efficiency should be reduced. If the material is 1.2 meters thick, choose a heavy-duty hammer crusher with a pre-crushing tooth roller. If the finished product needs to be finely divided (e.g., ≤30mm), pay attention to the equipment's grate gap adjustment range and screening accuracy.

Ingredients: If the material contains impurities (such as iron in coal or rebar in construction waste), choose a model with a built-in iron removal device to prevent impurities from striking the hammer head and causing damage, thereby reducing equipment failure rate.

2. Capacity Requirements: Avoid "a big horse pulling a small cart" or "a small horse pulling a big cart"

Calculate the actual capacity required based on the production line's average daily throughput, annual operating days, and equipment operating hours. Consider the difference between the equipment's theoretical capacity and actual capacity (typically, a 20% margin should be reserved for theoretical capacity to account for fluctuations in material supply and equipment maintenance in actual production) to determine the equipment model:

If the average daily throughput is 500 tons, the plant operates 300 days a year, and operates 10 hours per day, the hourly capacity requirement is 50 tons/hour. Select a model with a theoretical capacity of 60-70 tons/hour (such as the PC-800).

Blindly selecting a model with a theoretical capacity of 100 tons/hour may meet the requirements, but the equipment purchase cost will increase by over 30%. Furthermore, the daily operating energy consumption (for example, increasing motor power from 37kW to 75kW) and maintenance costs will also increase accordingly, resulting in a waste of resources.

3. Production Site: Constraints on Equipment Installation and Layout

Consider the site's space dimensions, load-bearing capacity, and power supply conditions:

Space Dimensions: Hammer crushers require space for feeding, discharging, and maintenance. If the site is confined (e.g., a small construction waste disposal station), consider a mobile hammer crusher, which doesn't require a fixed foundation and can be flexibly relocated. If the site is spacious (e.g., a large mine), consider a fixed model to reduce equipment costs.

Load Capacity: Heavy hammer crushers (e.g., the PCZ-1615) weigh over 50 tons. Ensure the site's ground load capacity (at least 20kN/㎡) to prevent damage from ground collapse.

Power Supply Conditions: The voltage and power of the equipment's motor must match. If the production site is located in a remote area (e.g., a mine) with unstable power supply, select a model with dual power switching or diesel drive to ensure continuous operation.

Focus on Core Equipment Parameters: Identifying Equipment Performance

After clarifying your needs, you need to thoroughly analyze the equipment's core parameters. These parameters directly determine the equipment's crushing efficiency, service life, and product quality. Focus on the following five key areas:

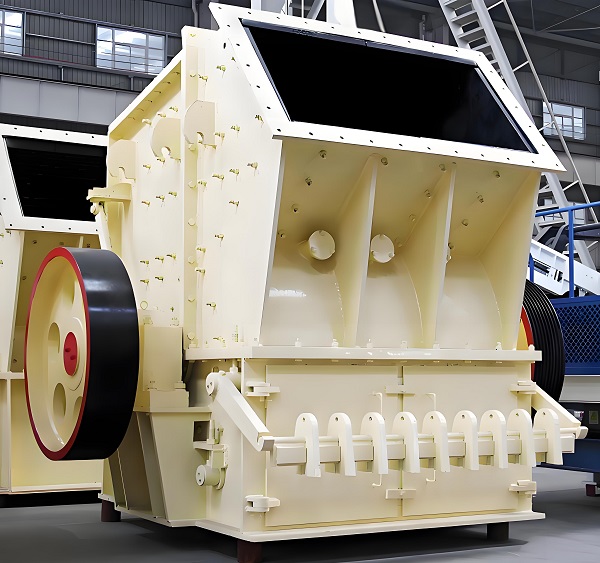

1. Crushing Chamber Design: Impacts Crushing Efficiency and Product Quality

The crushing chamber's structure, volume, and mesh angle directly impact the material crushing effect:

Structure: A "deep-chamber" crushing chamber increases material capacity and improves processing efficiency (15%-20% higher than a shallower chamber); an "involute-shaped" crushing chamber ensures uniform material load, reduces over-crushing, and reduces the fines content in the finished product (from 15% to below 8%).

Volume: The crushing chamber volume must match the equipment's production capacity. If the volume is too small, "feed jamming" is likely to occur. If the volume is too large, the material will remain in the chamber for an extended period, increasing hammer wear.

Meshing Angle: The mesh angle (the angle between the two walls of the crushing chamber) is typically controlled within 100°C. 20°-30°. An angle that is too large can cause material rebound and reduce crushing efficiency. An angle that is too small can increase the height of the crushing chamber and take up more space.

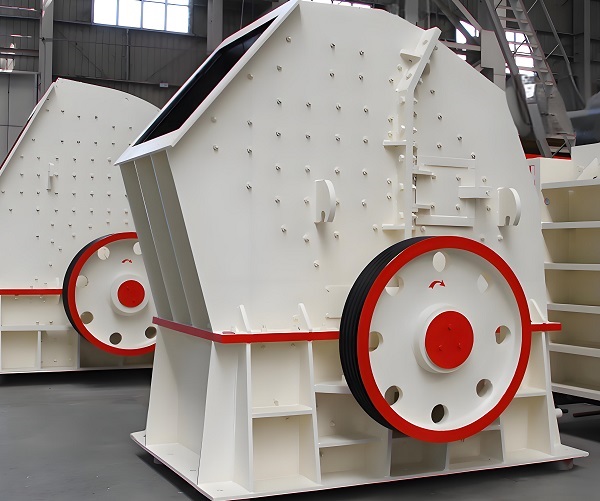

2. Hammer Quality: Determines Equipment Maintenance Costs and Operational Stability

The hammer is the core, consumable component of a hammer crusher. Its material, structure, and quantity directly impact its service life and crushing performance:

Material: Common hammer materials include high-manganese steel (ZGMn13), high-chromium alloy, and bimetallic composite. High-manganese steel hammers offer excellent toughness and are suitable for handling materials with high impurities (such as construction waste), with a lifespan of approximately 2-3 months. High-chromium alloy hammers offer high hardness and are suitable for handling hard and brittle materials (such as limestone), with a lifespan of approximately 4-6 months. Bimetallic composite hammers (high-manganese steel base + high-chromium alloy working layer) combine toughness and hardness, with a lifespan of up to 6-8 months. However, they are more expensive (50% higher than high-manganese steel hammers). The choice should be based on material characteristics and budget.

Structure: The "combined hammer" allows for individual replacement of worn parts, reducing replacement costs (30% less than a one-piece hammer). The "streamlined hammer" reduces material impact resistance, improving crushing efficiency while also reducing noise (from 95 decibels to 85). decibels);

Quantity: The number of hammers must match the motor power. Too many hammers can easily overload the motor, while too few can reduce crushing efficiency. A reasonable configuration should be made based on the equipment model and material characteristics.

3. Motor Performance: The "Power Heart" of Equipment Operation

The motor is the power source of the equipment, so pay attention to its power, speed, and protection level:

Power: The motor power must match the equipment's capacity. For example, a 50-ton/hour machine requires a 37-45kW motor, and a 100-ton/hour machine requires a 75-90kW motor. Insufficient power can cause the machine to stall (motor overload and shutdown), while excessive power increases energy consumption.

Speed: The hammer speed directly affects crushing force. The speed range is typically 800-1500 rpm. Hard and brittle materials require higher speeds (1200-1500 rpm), while tough materials require lower speeds (800-1000 rpm). Choose a motor with adjustable speed to maximize equipment compatibility.

Protection Level: If the equipment is used in humid environments (such as open-pit mines and sewage treatment plants), the motor protection level must meet IP54 or higher (dust and water-resistant) to prevent short circuits and malfunctions caused by water ingress.

4. Grate Assembly: Controlling Product Particle Size and Preventing Clogging

Grate bars are key components in determining product particle size. Pay attention to their material, gap adjustment range, and anti-clogging design:

Material: Grate bars should be made of wear-resistant materials (such as high-manganese steel or wear-resistant cast iron) to prevent wear that increases gaps and affects the accuracy of the finished product particle size.

Gap Adjustment Range: Grate bar gaps should be flexibly adjustable (e.g., 10-50mm) to meet varying finished product particle size requirements. If producing a variety of finished product specifications, choose a machine with convenient gap adjustment (such as hydraulic adjustment, which reduces adjustment time from 30 minutes to 5 minutes).

Anti-clogging Design: If processing high-moisture content materials, choose vibrating or curved grates. These use vibration or special structures to prevent clogging, improving equipment operating efficiency (from 80% to over 95%).

5. Safety Protection: Preventing Production Accidents and Equipment Damage

Safety protection ensures the long-term stable operation of the equipment. Check that the equipment is equipped with the following safety devices:

Overload Protection: If the equipment stalls, overload protection devices (such as hydraulic push rods and torque limiters) automatically shut down the machine to prevent motor burnout or component damage.

Protective Covers: Moving parts such as the crushing chamber and pulleys must be equipped with protective covers to prevent accidental operator contact and accidents.

Emergency Stop Button: Emergency stop buttons must be installed on the operation panel and both sides of the machine body to ensure rapid shutdown in emergencies.

Investigate the Manufacturer's Capacity: Avoid the Risk of "Small Factory Substandard Products"

There are numerous hammer crusher manufacturers on the market. Some small manufacturers engage in "cutting corners" (e.g., using ordinary steel instead of high-manganese steel hammer heads) and "false advertising" (exaggerating equipment capacity and lifespan). Therefore, it's important to examine the manufacturer's capabilities in the following four areas:

1. Qualifications and Reputation: Choose a "Reliable Manufacturer"

Qualifications: Prioritize manufacturers with ISO9001 quality system certification and a mining machinery production license. These qualifications are essential for ensuring equipment quality.

Reputation: Analyze the manufacturer's reputation through industry exhibitions, customer case studies, and online reviews. If a manufacturer has at least three years of industry experience, has served well-known companies (such as large cement plants and mining companies), and has a customer repurchase rate exceeding 30%, their products and services are reliable.

Avoid "three-no" manufacturers (no qualifications, no factory, and no case studies). While these manufacturers offer lower prices (20%-30% lower than legitimate manufacturers), their equipment has a shorter lifespan (possibly shortened from three years to one). Years), frequent failures, and extremely high subsequent maintenance costs.

2. Production Capacity and R&D Strength: Ensure equipment quality and technological advancement

Production Capacity: Inspect the manufacturer's production workshop to determine whether they have the ability to independently produce core components (such as hammers and crushing chambers)—if the manufacturer relies on purchased parts, problems such as poor compatibility and inconsistent quality are likely to occur.

R&D Strength: Inquire about whether the manufacturer has an R&D team and whether they have customized production capabilities (such as adjusting the equipment structure to suit specific material characteristics). Manufacturers with strong R&D capabilities (e.g., those that invest more than 5% of annual revenue in R&D) generally have equipment with better wear resistance and energy efficiency.

3. Customer Case Studies: Verify the Equipment's Effectiveness in Actual Application

The "customer cases" provided by the manufacturer are the most intuitive reference. Key considerations include:

Compatibility: Prioritize manufacturers with case studies using similar materials and production capacity. For example, for construction waste treatment, consider the equipment operating data provided by the manufacturer for other construction waste treatment plants (e.g., average daily throughput, hammer life, and failure rate).

On-site Inspection: If conditions permit, visit the manufacturer's customer sites to observe the equipment's operation and inquire about the operator's experience (e.g., ease of use, maintenance frequency, and after-sales service response speed) to avoid being misled by "fake case studies."

Focus on After-Sales Service: Reduce Equipment Operation and Maintenance Risks

After-sales service for a hammer crusher directly impacts the equipment's "lifecycle cost." Inadequate service can lead to equipment downtime for repairs (resulting in production line downtime, potentially costing over 100,000 yuan per day) and difficulty sourcing spare parts. Focus on the following three service areas:

1. Installation and Commissioning: Ensure Rapid Equipment Operation

The installation and commissioning of a hammer crusher requires the services of professional technicians. Otherwise, problems such as equipment level deviation and loose component connections can easily occur, impacting operational stability.

Confirm whether the manufacturer offers on-site installation and commissioning services and guarantees a commissioning timeframe (e.g., 7-10 days).

After commissioning, the manufacturer must provide operator training (including equipment operation, routine maintenance, and troubleshooting) to ensure they can operate the equipment independently.

2. After-Sales Service Response Speed: Reduce Downtime Losses

Failures are inevitable during equipment operation, and after-sales service response speed is crucial:

It is important to clarify the manufacturer's "after-sales service commitment," such as providing a solution within 2 hours of receiving a fault notification and dispatching a technician within 24 hours (no more than 48 hours in remote areas).

Inquire whether the manufacturer has a local service point and spare parts inventory. If the manufacturer has a local point of contact, the spare parts procurement cycle can be shortened from 7 days to 1-2 days, significantly reducing downtime.

3. Parts Supply: Ensure Long-Term Equipment Operation

Hammer crusher consumable parts (such as hammer heads, grates, and liners) require regular replacement. It is important to confirm:

Whether the manufacturer provides a long-term and stable supply of spare parts and whether spare parts pricing is transparent (to avoid price increases later, such as a hammer head price increase from 500 yuan to 800 yuan).

Parts delivery time (e.g., 1-3 days for standard parts and 7 days for special parts) to avoid long-term equipment idleness due to parts shortages.

Compare Quotes and Contract Terms: Avoid "Hidden Costs"

After comprehensively considering the equipment and the manufacturer, be cautious when interpreting quotes and contracts to avoid losses due to "low-price temptations" or "contract loopholes":

1. Quote Comparison: Focus on the "Total Price" and "Itemized Quotes"

Don't simply compare the "total equipment price." Ask the manufacturer to provide "itemized quotes" (e.g., the equipment itself, motor, iron removal device, dust removal system, installation and commissioning fees, training fees). Be clear about which items are included in the quote and which require additional fees (e.g., shipping fees, taxes).

Be wary of "low-price quotes." Some manufacturers, to attract customers, may quote only the equipment itself, adding additional charges for installation, commissioning, and accessories. The final total cost may be 10%-20% higher than the official quote.

2. Contract Terms: Clarify Rights, Responsibilities, and Guarantees

When signing a contract, carefully review the terms, focusing on clarifying:

Equipment quality commitments: such as the equipment warranty period (usually one year or 1,000 hours of operation, with core components like motors covered for two years); the procedures for handling quality issues during the warranty period (such as free repair or replacement);

Delivery Time and Payment Methods: Clarify delivery times (to avoid delays and disruptions to production line commissioning); payment ratios (such as 30% upfront, 50% upon arrival and acceptance, and 20% upon expiration of the warranty period, to reduce payment risks);

Liability for Breach of Contract: Liability for breach of contract (such as liquidated damages, returns, or exchanges) if the manufacturer fails to deliver on time or if the equipment does not meet quality standards. The buyer's responsibilities should also be clearly defined if they fail to pay on time.

Summary: The "Decision-Making Logic" for Purchasing a Hammer Crusher

Purchasing a hammer crusher is a systematic process from requirements to implementation. The core principles can be summarized as follows:

First, determine requirements: Clarify material characteristics, production capacity, and site conditions to avoid blind selection.

Model;

Next, examine the parameters: Focus on core parameters such as the crushing chamber, hammers, motor, and grates to identify equipment performance;

Choose the right manufacturer: Examine qualifications, production and R&D capabilities, and customer case studies to mitigate quality risks;

Guaranteed service: Confirm installation and commissioning, after-sales response, and spare parts availability to reduce operational costs;

Sign contracts carefully: Compare quotes and review contract terms to avoid hidden costs and legal risks.

Through these steps, you can ensure that the hammer crusher you choose not only meets your current production needs but also has the potential for long-term stable operation, providing reliable assurance for efficient and cost-effective production line operation.