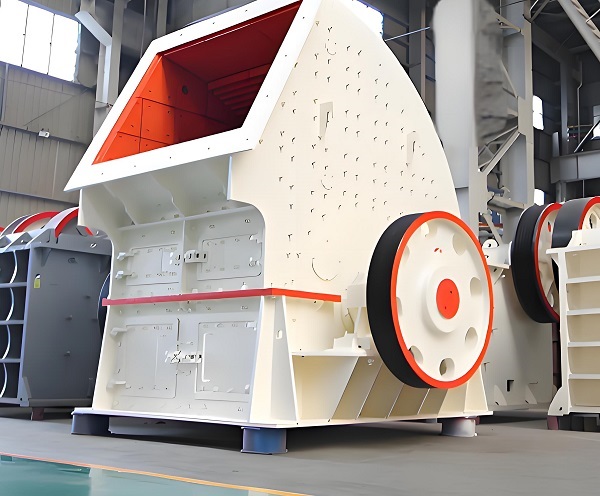

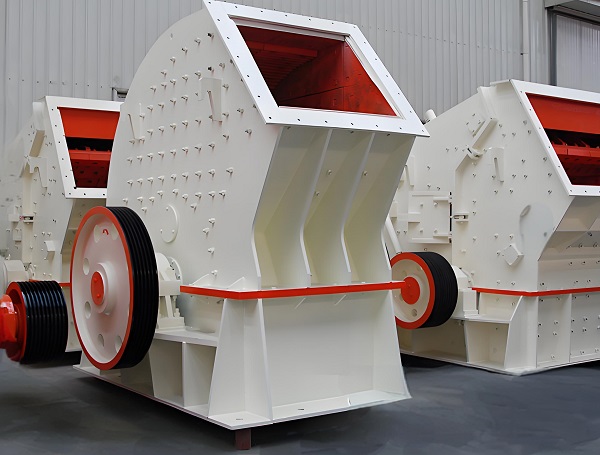

Among industrial crushing equipment, hammer crushers, with their core advantages of simple structure, high crushing efficiency, and manageable costs, have become the mainstream equipment for processing low- to medium-hardness materials. Using high-speed rotating hammers to impact, shear, and grind the material, they achieve rapid crushing. They are particularly suitable for materials with a hardness of 6 or less on the Mohs scale, such as limestone, coal, construction waste, and biomass. From coarse ore crushing in mining to aggregate preparation in the building materials industry, from coal crushing in the power industry to solid waste treatment in the environmental protection sector, hammer crushers, with their adaptability, ease of operation, and low maintenance costs, are widely used in various industrial sectors. They provide key support for large-scale production and efficient resource utilization across various industries, making them a classic and cost-effective piece of industrial crushing equipment.

Mining Industry: Efficient Primary Crushing and Pretreatment of Medium- and Low-Hardness Ores

In the mining industry, hammer crushers, with their high crushing efficiency and simple process flow, have become core equipment for primary crushing and pretreatment of medium- and low-hardness ores (Mohs hardness 3-6), such as limestone, gypsum, and shale. Compared to traditional jaw crushers, hammer crushers eliminate the need for complex feed adjustment mechanisms and can directly process raw ore with a particle size of ≤1.2 meters. The crushed material is uniform in size, eliminating the need for additional shaping equipment, significantly simplifying the production process.

A large limestone mine in my country, primarily used for cement production, produces raw ore with a particle size of up to 1 meter and a hardness of 3-4 on the Mohs scale. Previously, a jaw crusher was used for primary crushing, with a single unit capacity of only 500 tons/hour. Furthermore, the crushed material contained as much as 15% needle-like flakes, necessitating subsequent shaping with a vertical shaft impact crusher, increasing equipment investment and energy costs. The introduction of the PCZ-1615 heavy-duty hammer crusher has significantly improved production efficiency. This equipment, featuring a "multi-row hammer + grate discharge" design, directly crushes raw ore to less than 50mm, increasing the processing capacity of a single unit to 1,200 tons/hour, 2.4 times that of the existing equipment. The flake content of the crushed material is reduced to less than 8%, fully meeting the aggregate grading requirements for cement production. This eliminates the need for grading, reduces equipment investment costs by 40%, and reduces unit energy consumption from 12kWh/ton to 8kWh/ton, resulting in annual energy savings of over 6 million yuan.

Hammer crushers have also performed exceptionally well in international mining scenarios. At a gypsum mine in India, the ore has a high moisture content (15%-20%), making traditional crushing equipment prone to clogging and sticking to the wall. The adoption of a hammer crusher equipped with an anti-stick liner and high-frequency vibrating grates reduces material sticking thanks to the liner's smooth surface, while the vibrating grates promptly discharge crushed material. This reduced the equipment's blockage rate from 30% to below 5%, extending the average daily operating time from 12 hours to 18 hours. The gypsum mine's annual production capacity has increased by 50%, providing a stable supply of gypsum raw materials for the local building materials market.

2. Building Materials Industry: Large-Scale Preparation of Aggregates and Powders

In the production of building materials such as cement, concrete, and wall materials, the preparation of aggregates and powders is a core process. Hammer crushers, with their advantages of high crushing ratios and adjustable product particle size, have become key crushing equipment in the building materials industry. Whether preparing concrete aggregates or crushing cement raw materials, hammer crushers can precisely control product particle size by adjusting the hammer speed and grate gap to meet the production needs of different building materials. A large cement company in my country requires crushing a mixture of limestone, clay, and iron powder to less than 80mm for raw meal production. The company previously employed a two-stage crushing process consisting of a jaw crusher and a cone crusher, which occupied 800 square meters of equipment. This process was complex and prone to uneven material mixing. Switching to a single PCF-2018 impact hammer crusher, the company now meets this requirement with only one stage of crushing. This equipment utilizes the synergistic action of the impact plate and hammers to crush the mixture to less than 80mm, improving the uniformity of the crushed material by 20% and eliminating energy waste in the subsequent raw meal homogenization process. The single unit has a processing capacity of 1,800 tons/hour, while the equipment footprint has been reduced to 400 square meters (a 50% reduction). The number of maintenance personnel has been reduced from 8 to 4, saving over 3 million yuan in annual labor and maintenance costs.

Hammer crushers are also widely used in the production of wall materials. A new building materials factory in my country produces lightweight partition boards from bricks and blocks found in construction waste. The raw materials need to be crushed to particles smaller than 30mm. They use a small PC-800 hammer crusher, capable of processing 80 tons/hour. The crushed material produces a uniform particle size, allowing it to be used directly in board production without screening. The equipment requires only one-third the investment of a traditional crusher and is easy to operate, requiring only one hour of training for ordinary workers. The factory produces 1.5 million square meters of lightweight partition boards annually, repurposing construction waste as a resource and generating annual revenue exceeding 80 million yuan.

3. Power Industry: Energy Saving and Safety Assurance in Coal Crushing

In the thermal power generation industry, coal is the primary fuel, and its crushing quality directly impacts boiler combustion efficiency and operational safety. Excessively large coal particle size can lead to incomplete combustion within the boiler, increasing carbon emissions and energy consumption. Contamination of the coal with impurities such as iron and stone can cause boiler coking and equipment damage. Hammer crushers, with their dual functions of "efficient crushing and impurity separation," have become core equipment for coal pre-processing in the power industry.

A large thermal power plant in my country consumes 10 million tons of coal annually and needs to crush raw coal to a size of less than 50 mm for combustion in boilers. The original roller crusher used this method. However, due to the frequent contamination of the raw coal with impurities such as iron lumps and gangue, the rollers needed to be replaced monthly. Each replacement resulted in over 8 hours of downtime, severely impacting power generation efficiency. The introduction of the PCK-1416 hammer crusher, equipped with a "de-ironing device and wear-resistant hammers," has significantly improved the situation. The device's built-in electromagnetic de-ironing device automatically separates iron from raw coal (with a separation rate of 98%), preventing wear on the hammers caused by impurities. The use of high-manganese steel hammers has extended the service life from one month to six months, reducing equipment downtime and maintenance from 96 hours per year to 16 hours per year. The resulting coal has a more uniform particle size, improving boiler combustion efficiency by 5%, and increasing power generation per ton of coal from 300 kWh to 315 kWh, generating an additional 150 million kWh of annual power generation and generating over 60 million yuan in additional revenue.

Hammer crushers also play a vital role in biomass power generation. A biomass power plant in my country, using straw and wood chips as fuel, needs to crush the raw materials to a size of less than 30 mm. The PCF-1010 hammer crusher, designed specifically for biomass, utilizes a "sharp hammer head + wide-gap grate" design to prevent straw from entanglement. A single unit can process up to 50 tons/hour. The moisture content of the crushed material is kept below 20% (assisted by a built-in drying device), meeting the moisture requirements for biomass fuel used in boiler combustion. This improves biomass fuel combustion efficiency by 8%, reduces annual standard coal consumption by 2,000 tons, and complies with national energy conservation and emission reduction policies.

4. Environmental Protection Industry: An Economical Choice for Solid Waste Reduction and Resource Utilization

In the environmental protection sector, the reduction and resource utilization of municipal solid waste, construction waste, and industrial solid waste place extremely high demands on the economic efficiency and adaptability of crushing equipment. Hammer crushers, with their advantages of low cost, easy maintenance, and ability to process mixed materials, have become the preferred equipment for solid waste treatment in the environmental protection industry. Their cost-effectiveness is particularly prominent in small and medium-sized solid waste treatment projects. A municipal waste treatment plant in my country uses a "crushing + incineration" process to treat domestic waste, requiring it to be shredded to sizes below 80mm. The original plant used a dedicated garbage crusher, which required high equipment investment (over 5 million yuan) and complex maintenance, with annual maintenance costs exceeding 1 million yuan. Switching to two PCZ-1210 heavy-duty hammer crushers reduced equipment investment to 2 million yuan (a 60% reduction), while maintaining these crushers is much simpler. The hammer heads, made of high-chromium alloy, have a service life of three months, and replacement takes only two hours. Each unit has a daily processing capacity of 300 tons, and two units can meet the city's daily waste shredding needs of 600 tons. The crushed waste volume is reduced by 40%, and the incinerator's thermal efficiency is increased by 10%, saving over 8 million yuan in annual incineration costs.

Hammer crushers have also proven successful in industrial solid waste treatment. A machinery manufacturing company in my country generates a large amount of scrap castings (cast iron and steel) annually, which require crushing and recycling. Using a PC-1000 hammer crusher, the company adjusts the hammer speed and discharge gap to crush the scrap castings into varying particle sizes of 50-100mm, meeting the feed requirements of various smelting furnaces. The equipment achieves a crushing efficiency of 20 tons/hour and a 98% scrap casting recovery rate. The company recycles 1,000 tons of scrap metal annually, generating over 5 million yuan in recycling value. This reduces the amount of solid waste going to landfill, meeting environmental requirements.

5. Advantages and Development Trends of Hammer Crusher Applications

Based on application cases across various industries, the advantages of hammer crushers can be summarized into three key points: First, they are cost-effective, with a simple structure and low manufacturing and maintenance costs, making them suitable for small- to medium-sized production projects and businesses with limited budgets. Second, they are highly efficient and flexible, with high crushing efficiency and adjustable product particle size, allowing them to process a variety of mixed materials with medium and low hardness, demonstrating strong adaptability. Third, they are easy to operate, requiring no complex technical skills, and can be quickly started and stopped, making them suitable for continuous production.

With the development of green and intelligent industry, hammer crushers will be upgraded in two directions in the future: first, optimizing environmental performance. Improvements to sealing structures and dust removal systems will further reduce dust and noise emissions, meeting higher environmental standards. Second, they will be upgraded to intelligent features. These include intelligent sensors and control systems that monitor the equipment's operating status and material crushing progress in real time, automatically adjusting crushing parameters, and enabling "unmanned" operation, reducing labor costs and improving operational stability.

It can be foreseen that in the field of crushing medium and low hardness materials, hammer crushers will continue to maintain their mainstream position, and continuously expand their application boundaries through technological upgrades, providing more economical and practical crushing solutions for efficient production and sustainable development in industries such as mining, building materials, electricity, and environmental protection.