This article combines the structural characteristics of air separators with practical experience, and elaborates on pre-installation preparation, core installation process, phased commissioning and safety regulations to ensure that the equipment can be put into use quickly and achieve optimal performance.

This article focuses on three core scenarios: household waste, industrial waste, and construction waste. It systematically analyzes the adaptation range, treatment effect, and technical points of the drum screen, while clarifying the types and reasons for unsuitable waste.

Starting from the core principles of vibrating screens, this article provides a detailed explanation of power transmission, material layering mechanism, and specialized structural design for waste disposal. It also offers targeted daily maintenance standards, providing scientific guidance for efficient operation and extended service life of equipment.

This article will systematically analyze the core role, suitable types, and application cases of shredders in different waste treatment scenarios, providing technical reference for waste treatment projects.

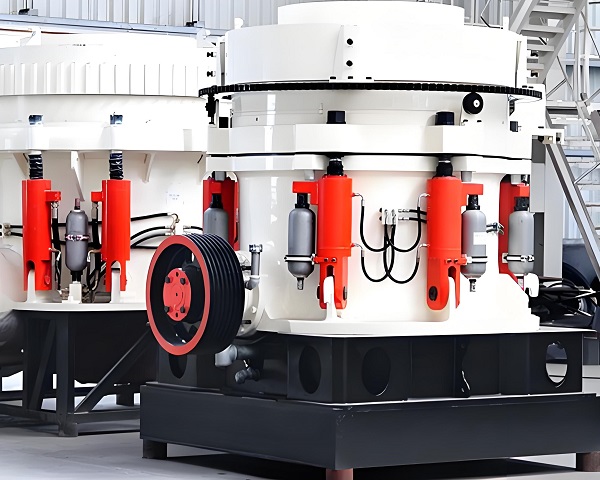

This article will systematically dissect the structural features and technical advantages of the hydraulic cone crusher, and explain its value in combination with actual application scenarios, providing technical reference for high-end recycled aggregate production projects.

This article will systematically analyze the technical characteristics, application scenarios, core advantages, and combination solutions of various types of equipment, providing a comprehensive reference for construction waste crushing projects.

This article will comprehensively analyze the technical value and practical advantages of single cylinder cone crushers from two aspects: core characteristics and prominent advantages, combined with practical application cases.

The maintenance of cone crushers should follow the principle of first identifying the root cause, then precise repair, and finally long-term prevention. Based on different types of faults and the structural characteristics of the equipment, maintenance plans should be developed. At the same time, a prevention system should be established through daily inspections, regular maintenance, and personne...

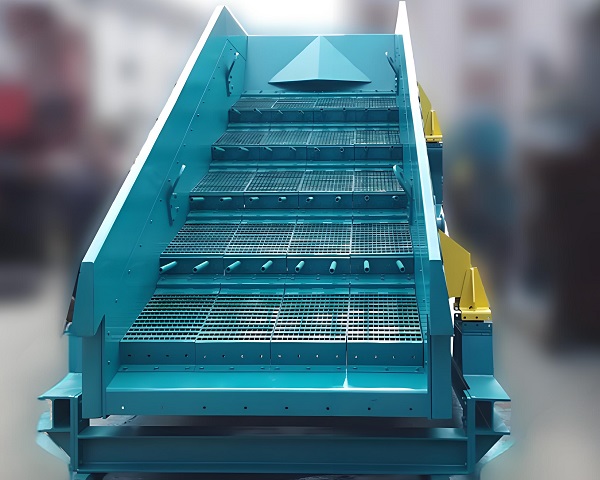

Finger Screens achieve efficient screening of large, hard, and impurity-containing materials through scientific material selection and design optimization.

The large garbage removal screen uses the principle of physical screening to accurately separate large impurities from materials, providing qualified raw materials for subsequent processes. It is the core equipment to ensure the stable, efficient, and safe operation of the production line.