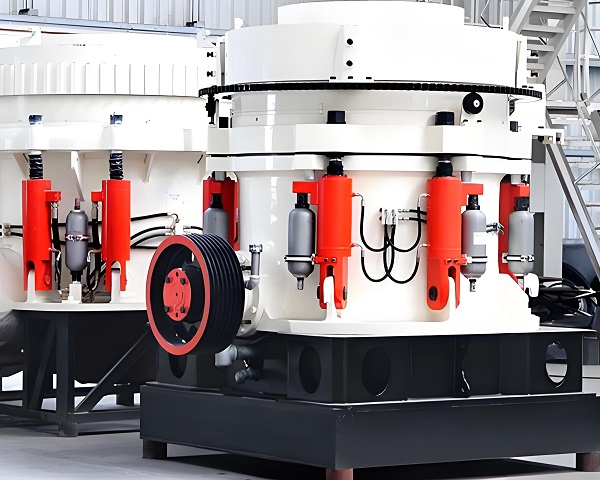

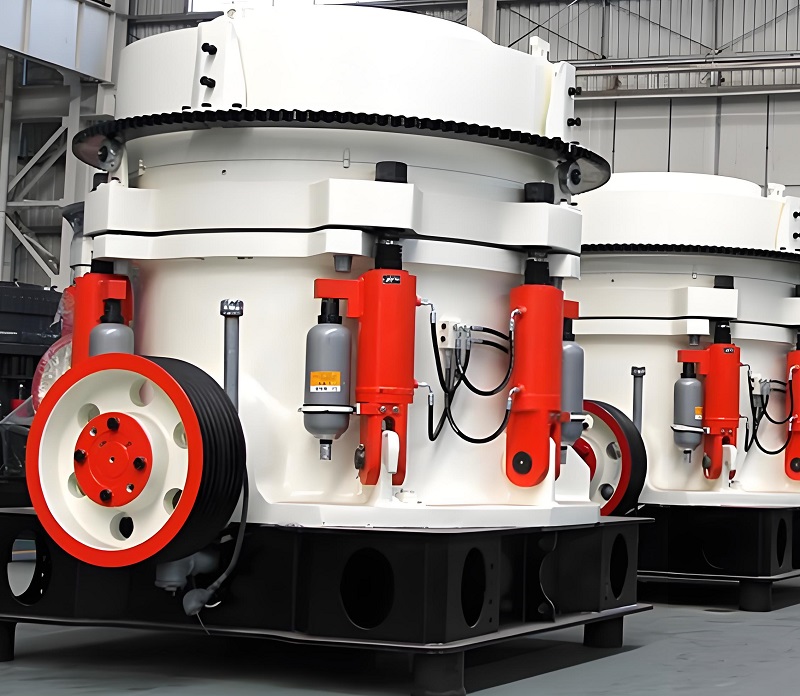

As the core equipment for processing medium hard materials in industries such as mining and construction, cone crushers are widely used due to their advantages of large crushing ratio and uniform product particle size. However, if they are subjected to high load and strong impact conditions for a long time, they are prone to faults such as crushing chamber blockage, bearing overheating, and reduced production. If not repaired in a timely manner or with improper methods, it will significantly shorten the equipment life and increase operating costs. This article focuses on the 8 core faults of cone crushers, and provides a systematic maintenance plan and practical skills from four dimensions: "fault phenomenon cause analysis maintenance steps prevention techniques".

Broken cavity blockage:

Quickly clear blockage+investigate the root cause to avoid secondary damage

1. Fault phenomenon

During equipment operation, there may be severe vibrations, sudden increases in current (exceeding the set value by more than 120%), material accumulation at the feed inlet, and no material discharge at the discharge outlet. Some models may trigger overload protection shutdown.

2. Core causes

Excessive feed particle size: Large pieces of material exceeding the equipment processing limit (such as ore exceeding the maximum feed inlet size of the crushing chamber) are mixed into the raw ore and stuck between the crushing chamber and the moving cone;

The discharge port is too small: the discharge port is not adjusted according to the hardness and crushing requirements of the material, and the crushed material cannot be discharged in a timely manner, accumulating in the cavity;

Excessive humidity/viscosity of materials: Wet and sticky materials with a moisture content exceeding 15% (such as wet coal and clay) adhere to the inner wall of the crushing chamber, forming an "arch" blockage;

Transmission system failure: Eccentric shaft, gears and other transmission components are stuck, causing the cone to not swing normally and the material to not be broken and discharged.

3. Maintenance steps

Emergency shutdown and safety protection: immediately cut off the power supply of the equipment, hang a warning sign "Do not start during maintenance" to avoid misoperation; If the equipment does not have an automatic pressure relief device, manually release the hydraulic system pressure (to prevent accidental movement of hydraulic components during maintenance).

Clearing operation:

Mild blockage (only accumulation at the discharge port): Open the cleaning door below the discharge port, use a dedicated hook rod (length ≥ 2 meters, to avoid personnel approaching the danger zone) to clean the accumulated materials, and if necessary, start the auxiliary vibration motor (if equipped) to accelerate the discharge;

Severe blockage (crushing large blocks in the crushing chamber): First, use a hydraulic jack to lift the starting cone (lifting height ≤ 50mm to prevent damage to the seal), insert a hard pad (thickness 10-20mm, material Q235 steel) into the gap between the moving cone and the fixed cone to fix it, then use a jaw crusher to crush large blocks in the crushing chamber, remove the pad after crushing, and slowly lower the moving cone;

Wet and sticky material blockage: Remove the observation door on the side of the crushing chamber, rinse the adhered material with a high-pressure water gun (pressure 0.8-1.2MPa), and clean the residual lumps with a scraper. Be careful to avoid water flow into the bearing chamber (cover the bearing end cover with waterproof cloth in advance).

Root cause investigation: After clearing the blockage, check whether the feeding screening equipment (such as rod screen) is malfunctioning (if the screen is damaged, it needs to be replaced), adjust the size of the discharge port (increase the discharge port by 5-10mm through a hydraulic adjustment device, and gradually optimize according to the product particle size), and detect the operating status of the transmission system (such as gear mesh clearance and eccentric shaft rotation flexibility).

4. Prevention techniques

Add a "dual stage screening" before feeding: the first stage uses a bar screen to intercept large pieces of material (materials with a particle size 1.2 times larger than the feeding port are directly removed), and the second stage uses a vibrating screen to control the moisture content of the material (equipped with a drying device to process wet and sticky materials);

Install "Intelligent Feed Monitoring": Install infrared sensors and current monitoring modules at the feed inlet. When the feed volume exceeds the equipment load or the current is abnormal, the feeder speed will be automatically reduced to avoid overload blockage;

Regularly clean the crushing chamber: After each shift, check the inner wall of the crushing chamber, use a scraper to clean residual materials, and rinse the equipment for wet and sticky material processing conditions with a high-pressure water gun once a week.

Bearing overheating: precise positioning of heat source to avoid bearing sintering

1. Fault phenomenon

The temperature of the bearing end cover exceeds 75 ℃ (normal operating temperature of 40-60 ℃), and the equipment's operating noise increases (with "buzzing" abnormal noise). In severe cases, the bearing may lock up, causing the cone to be unable to rotate.

2. Core causes

Lubrication failure: Insufficient, deteriorated or mismatched lubricating grease (such as using high-temperature lubricating grease in low-temperature environments, resulting in poor fluidity), poor lubrication of bearing balls and raceways, and frictional heat generation;

Installation deviation: Improper fit clearance between the inner ring and eccentric shaft of the bearing, and between the outer ring and the bearing seat (interference exceeding 0.05mm can cause bearing deformation, and clearance exceeding 0.1mm can cause vibration friction);

Impurity intrusion: aging and damage of seals (such as O-ring cracking, dust cover deformation), dust and material particles entering the bearing chamber, exacerbating wear and heating;

Overload operation: The equipment operates beyond its rated load for a long time (such as excessive crushing ratio or continuous exceeding of feed rate), and the radial/axial load borne by the bearings exceeds the design value, resulting in increased friction.

3. Maintenance steps

Shutdown cooling: Immediately shut down the machine, remove the bearing end cover for heat dissipation, and wait for the temperature to drop below 50 ℃ before disassembling (to avoid forcefully disassembling at high temperatures that may cause component deformation);

Disassembly inspection:

Remove the bearing seat bolts and take out the bearing (if the bearing is locked, use a heating device to heat the bearing to 80-100 ℃, and use the principle of thermal expansion and contraction to remove it. Violent tapping is prohibited);

Check the wear condition of the bearings: If there is pitting, scratching (depth exceeding 0.2mm) or cage fracture on the ball/raceway, the bearings need to be replaced as a whole; If there is only slight wear, fine sandpaper (800 grit or more) can be used to polish the surface and remove impurities;

Check the seals: replace the aging O-ring and dust cover (it is recommended to use fluororubber material, temperature resistance -20-200 ℃, wear resistance better than ordinary rubber), apply sealant (model Letai 596, enhance sealing effect).

Lubrication and installation:

Choose suitable lubricating grease: Lithium based grease (model GB/T 7324-2010) is used for normal temperature conditions (-10-40 ℃), and composite lithium based grease is used for high temperature conditions (40-80 ℃), with a filling amount of 1/2-2/3 of the internal space of the bearing (too much can cause heating, too little can cause wear);

Accurate installation: Use a micrometer to measure the fit clearance between the inner ring of the bearing and the eccentric shaft (controlled at 0.02-0.04mm), and the clearance between the outer ring and the bearing seat (0.03-0.05mm). After installation, manually rotate the bearing to ensure no jamming sensation;

Trial operation testing: Start the equipment and run it without load for 30 minutes. Use an infrared thermometer to monitor the bearing temperature (which should be stable at 40-60 ℃), while monitoring the operating noise (which should not have obvious abnormal noise). If the temperature still exceeds 70 ℃, the installation clearance and lubrication situation need to be rechecked.

4. Prevention techniques

Establish a "lubrication management ledger": check the lubricating grease level (at 1/2-2/3 of the oil level) weekly, replace the lubricating grease once a month (every 2 weeks for humid and dusty conditions), clean the bearing chamber with kerosene before replacement to avoid mixing old and new lubricating grease;

Regular inspection of seals: Disassemble the bearing end cover every quarter to inspect the seals. If aging or damage is found, replace them immediately. At the same time, apply lubricating grease to the sealing surface to enhance the sealing performance;

Real time temperature monitoring: Install a temperature sensor on the bearing seat, connect it to the PLC control system, and automatically alarm when the temperature exceeds 70 ℃. Stop the machine for protection when the temperature exceeds 80 ℃ to avoid bearing overheating and damage.

3、 Decreased production: Investigation of the entire process from "feeding crushing discharging"

1. Fault phenomenon

The actual output of the equipment has decreased by more than 15% compared to the design value, and the particle size of the crushed product is uneven (the proportion of ultra coarse particles exceeds 10%). Some materials are directly discharged without sufficient crushing.

2. Core causes

Wear of crushing chamber: The wear of the fixed cone and dynamic cone lining plates exceeds the limit (the thickness of the lining plate is reduced from the original 200mm to below 50mm), the volume of the crushing chamber decreases, the residence time of the material is shortened, and the crushing is insufficient;

Abnormal frequency of cone oscillation: The eccentric shaft speed decreases (such as motor belt slipping, gear wear leading to reduced transmission efficiency), the number of cone oscillations decreases from the design value of 1000 times/minute to below 800 times, and the crushing efficiency decreases;

Uneven feeding: Fluctuations in the speed of the feeder or blockage of the feeding port can cause the equipment to be "full and hungry" at times, reducing the effective working time;

Blockage of discharge port: The speed of the conveyor belt below the discharge port is too slow or the belt deviates, and the crushed material cannot be conveyed in time, accumulating at the discharge port and blocking the crushing chamber.

3. Maintenance steps

Inspection and repair of broken cavity:

After stopping the machine, enter the crushing chamber (with a confined space work permit required and an oxygen concentration of ≥ 19.5% detected after ventilation). Measure the thickness of the lining plate with a tape measure. If the wear exceeds the limit, replace the lining plate (it is recommended to use high manganese steel ZGMn13 lining plate with a hardness of HRC50-55 and a service life three times that of ordinary carbon steel);

If the lining plate is only partially worn, "weld repair" can be used: use wear-resistant welding rods (model D256) to weld on the worn area, with a weld thickness of 10-15mm. After welding, use an angle grinder to polish it flat and restore the original shape of the crushing chamber.

Transmission system maintenance:

Check the motor belt: If the belt is loose (press the belt to sink more than 15mm), adjust the motor base bolt to tighten the belt; If the belt has cracks or wear (groove depth is 1/3 shallower than grinding), replace it with a new belt (choose a V-belt, the model is matched according to the motor power, such as B-type belt suitable for 55-75kW motors);

Check gear meshing: Disassemble the gearbox and measure the gear meshing clearance (normally 0.15-0.25mm). If the clearance exceeds 0.3mm, replace the gear or perform "scraping repair" on the gear, and replace the gearbox lubricating oil (model L-CKC220 industrial closed gear oil).

Optimization of feeding and discharging system:

Adjust the feeder: Check the feeder frequency converter to ensure stable speed (fluctuation ≤ ± 5%). If the feeder is stuck, clean the internal foreign objects and lubricate the transmission components;

Maintenance of conveyor belt: Adjust the tension of the conveyor belt (press the conveyor belt to sink ≤ 10mm), replace worn rollers, and ensure that the speed of the conveyor belt matches the discharge capacity of the equipment (for equipment with a production capacity of 200 tons/hour, the conveyor belt speed should be set to 1.2-1.5m/s).

4. Prevention techniques

Lining wear monitoring: Weld a "wear indicator block" (with a thickness of 50mm and the same material as the lining plate) on the lining plate. When the indicator block is worn flat, trigger an alarm prompt to replace the lining plate;

Regular lubrication of the transmission system: lubricate the motor bearings and gearbox with grease/oil every month, and check the belt tension and gear engagement every quarter;

Real time monitoring of output: Install a belt scale at the discharge port to monitor the output in real time. When the output drops by more than 10%, it will automatically prompt for troubleshooting to avoid long-term low load operation.

Other common fault maintenance and comprehensive prevention

1. Hydraulic system malfunction (insufficient pressure, oil leakage)

Fault phenomenon: There is no action when adjusting the discharge port of the hydraulic system, or the pressure gauge of the hydraulic station shows a pressure lower than the set value (normally 15-20MPa), and there is oil leakage at the joint of the hydraulic pipeline.

Repair steps: Check the hydraulic pump (if there is abnormal noise from the pump body and the pressure cannot be increased, replace the hydraulic pump); Replace the aging hydraulic oil pipe (using high-pressure rubber hose with a pressure resistance rating of ≥ 30MPa) and sealing ring; Clean the hydraulic oil filter element (if the filter element is clogged, replace it with a new one), and add hydraulic oil (model L-HM46 anti-wear hydraulic oil) to the oil mark mark.

Preventive tips: Replace hydraulic oil every six months, clean the filter element once a month, regularly check the sealing of pipeline joints to prevent air from entering the hydraulic system.

2. Abnormal swing of the cone (swing amplitude too large/too small)

Fault phenomenon: The swing amplitude of the moving cone fluctuates greatly, the material in the crushing chamber is subjected to uneven force, and the product particle size fluctuates greatly.

Repair steps: Check the wear of the eccentric shaft sleeve (if the wear exceeds 0.2mm, replace the eccentric shaft sleeve); Adjust the weight of the eccentric block (increase/decrease the counterweight to stabilize the swing amplitude of the dynamic cone at 5-8mm); Check the bearing clearance to ensure that the bearing operates without any jamming.

Preventive tip: Measure the amplitude of the dynamic cone swing every quarter, adjust it promptly if any abnormalities are found, and avoid long-term abnormal swing that may cause equipment vibration to intensify.

3. Construction of comprehensive prevention system

Daily inspection: Check the operating parameters of the equipment (current, temperature, noise) in each shift, with a focus on bearing temperature (≤ 70 ℃), hydraulic system pressure (15-20MPa), and feeding/discharging conditions. If any abnormalities are found, stop the machine immediately;

Regular maintenance: Conduct small maintenance once a week (cleaning equipment, checking lubrication), medium maintenance once a month (disassembling and inspecting bearings and seals), and major maintenance once a year (replacing liners, gears, hydraulic components);

Personnel training: Conduct "fault diagnosis and practical training" for maintenance personnel to ensure mastery of core skills such as bearing installation, lining plate replacement, hydraulic system maintenance, etc., and avoid secondary failures caused by improper operation;

Spare parts management: Establish inventory of key spare parts (bearings, liners, seals, hydraulic pumps) to ensure quick replacement in case of failure and reduce downtime (it is recommended that the spare parts inventory meet the demand for 3 months).

The maintenance of cone crushers should follow the principle of "first investigating the root cause, then accurately repairing, and finally long-term prevention". For different types of faults (blockage, overheating, production decline, etc.), maintenance plans should be developed based on the structural characteristics of the equipment. At the same time, a prevention system should be established through daily inspections, regular maintenance, and personnel training to minimize the occurrence of faults and extend the service life of the equipment. In practical operation, maintenance personnel need to strictly comply with safety regulations (such as confined space operations and high-voltage equipment operation procedures), avoid safety accidents, and ensure efficient and safe maintenance work.