In the system of garbage classification and resource utilization, vibrating screen is the core equipment for achieving efficient classification of garbage, and its screening effect directly determines the subsequent processing efficiency and resource recovery quality. The complex composition, high humidity fluctuations, and susceptibility to clogging and corrosion of garbage pose strict requirements for the stability of vibrating screens. This article starts from the core principle of "vibration excitation+gravity grading" for vibrating screens, and elaborates on the power transmission, material layering mechanism, and specialized structure design for waste treatment. Combined with practical application scenarios, targeted daily maintenance standards are provided to provide scientific guidance for efficient operation and extended service life of equipment, and to help improve the quality and efficiency of the waste treatment industry.

As a key classification device in the garbage treatment system

The vibrating screen works based on the synergistic effect of "vibration excitation+gravity classification", achieving efficient separation of garbage with different components and particle sizes through high-frequency vibration, and adapting to the needs of classification and treatment of household waste, industrial waste, and construction waste.

1. Power drive and vibration transmission mechanism

The core power source of the vibrating screen is the vibrating motor, which is usually symmetrically arranged with dual motors. Linear or elliptical vibration is generated by adjusting the phase angle of the motor. When the motor is running, the centrifugal force generated by the eccentric block is converted into periodic excitation force, which is transmitted to the sieve box through the motor base, causing the sieve box to drive the screen mesh to vibrate at high frequencies (usually 1500-3000r/min, amplitude 3-8mm). This vibration form can be adjusted according to the characteristics of the garbage: when dealing with loose garbage (such as waste paper, plastic bottles), linear vibration (vibration direction at an angle of 30 ° -45 ° to the screen surface) is used to accelerate the forward transportation of materials; When dealing with viscous or mixed waste (such as kitchen waste and plastic mixed waste), elliptical vibration (with a long axis angle of 20 ° -30 ° to the screen surface) is used to enhance the flipping effect of materials and avoid local accumulation.

2. Material layering and screening separation process

After garbage enters the screen surface, it undergoes multi-layer motion under vibration excitation: the upper layer of large particle materials (such as large bricks and stones, waste furniture fragments) are transported forward along the screen surface under inertial force and discharged from the end of the screen, becoming the material on the screen; Medium sized materials in the middle layer (such as cans and plastic bucket fragments) continuously roll during vibration, gradually passing through the corresponding aperture sieve and becoming intermediate fractions; The lower fine-grained materials (such as kitchen waste residue and dust) quickly pass through the sieve holes and fall into the lower feeding device, becoming undersized materials. Throughout the process, the inertial force generated by vibration overcomes the frictional and adhesive forces between garbage particles, especially for damp and viscous garbage. High frequency vibration can destroy the particle aggregation structure, allowing fine particles to be separated smoothly, and the screening efficiency is improved by more than 60% compared to traditional static screening.

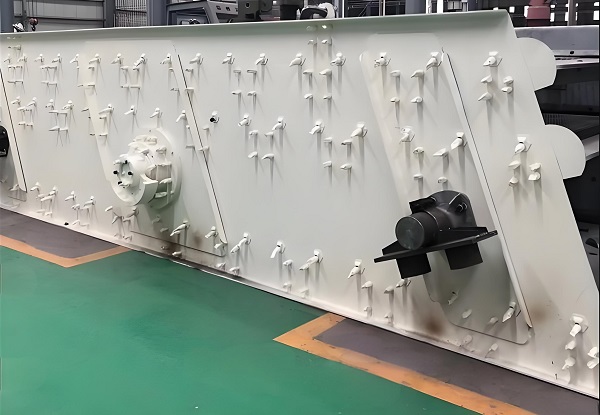

3. Specialized structure adaptation design for garbage disposal

In response to the complex composition of garbage (including hard, flexible, and viscous materials), the vibrating screen has undergone special structural optimization: 1 The screening surface adopts a multi-layer design (usually 2-3 layers), with the upper layer being a coarse sieve (aperture 20-50mm) to remove large impurities; The middle layer is a graded sieve with a pore size of 5-20mm, which separates recyclable materials such as plastics and metals; The lower layer is a fine sieve (with a pore size of 1-5mm), which filters fine material residue and achieves "one sieve, multiple stages" separation. 2. The screen material should be wear-resistant and anti adhesive, such as polyurethane screen (smooth surface, reducing adhesive waste adhesion rate by 40%) and stainless steel screen (corrosion-resistant, suitable for industrial waste containing acid and alkali components). 3. The screening box adopts a sealed design, equipped with a dust cover and rubber sealing strip, to prevent the leakage of dust and odors generated during the garbage screening process, which meets environmental protection standards.

Daily maintenance standards for vibrating screen screening of garbage

In the scenario of garbage disposal, vibrating screens face problems such as high material impurities, large humidity fluctuations, and easy blockage and corrosion. It is necessary to establish a full process system of "targeted cleaning+periodic inspection+preventive maintenance" to ensure stable operation of the equipment.

1. Daily cleaning: Focus on solving blockage and corrosion problems

Screen cleaning: After daily work, the screen must be thoroughly cleaned to avoid residue and adhesion of garbage. When dealing with dry garbage such as waste paper and plastic, use a high-pressure air gun (pressure 0.4-0.6MPa) to blow back from below the sieve to remove small particles stuck in the sieve holes; When dealing with wet and viscous garbage (such as kitchen waste and sludge), use a high-pressure water gun (water pressure 0.3-0.5MPa) to rinse, combined with a neutral cleaning agent (to avoid corroding the sieve). After rinsing, turn on the equipment and run it for 5 minutes without load to drain the water. Perform a deep cleaning once a week, remove the screen frame, clean the stubborn adhesive on the edges of the screen and the inner wall of the screen box to prevent deformation of the screen.

Cleaning of the body and components: Clean the exterior of the screen box, motor casing, feed inlet, and discharge channel daily to prevent impurities from entering key components such as motors and bearings. For industrial waste containing corrosive components (such as chemical waste and battery residue), the equipment surface should be rinsed with clean water after operation, wiped dry, and coated with rust inhibitor (such as mechanical oil) to prevent corrosion of metal parts. The sealed sieve box needs to be cleaned inside the dust cover every week to avoid dust accumulation that affects vibration transmission.

2. Periodic inspection: monitoring the status of key components

Daily inspection items: Before starting up, check whether the screen mesh is damaged or loose, and whether the tightening torque of the screen mesh frame bolts meets the standard (usually 8-12N · m); Check whether the fixing bolts and spring supports of the vibration motor are loose. If the bolts are found to be loose, they should be tightened in a timely manner to prevent the components from falling off during the vibration process. Monitor the running noise of the motor and bearings during operation, and there should be no sharp abnormal noise during normal operation. If there is a "buzzing" or metal friction sound, the machine should be stopped immediately for troubleshooting; Touch the temperature of the motor casing. The normal temperature should be below 75 ℃. If it exceeds 80 ℃, the machine should be stopped for cooling and the heat dissipation should be checked.

Weekly inspection items: Check whether the phase angle of the eccentric block of the vibration motor is consistent to ensure that the vibration trajectory meets the design requirements (linear vibration or elliptical vibration). If the phase angle deviates, it needs to be recalibrated; Check the shock-absorbing spring for deformation, breakage, or elastic attenuation. If there is any debris wrapped around the surface of the spring, it should be cleaned in a timely manner to ensure the shock-absorbing effect (the normal compression of the spring should be uniform, with a deviation of no more than 2mm). Check the sealing condition of the sieve box. If the sealing strip is found to be aged or damaged, it should be replaced in a timely manner to prevent dust leakage; Check if the feeding device (such as feeder, fabric feeder) is blocked to ensure uniform feeding.

Monthly inspection items: Disassemble the motor end cover, check the lubrication condition of the bearings. The bearings should be filled with lithium based grease (model L-AN46), with a filling amount of 1/2-2/3 of the internal space of the bearings. If the grease deteriorates or turns black, it needs to be thoroughly cleaned and refilled; Check the insulation performance of the motor coil and measure the insulation resistance with a multimeter, which should be greater than 1M Ω to avoid short circuits caused by moisture. Check the wear of the screen mesh and measure the size of the sieve holes. If the wear exceeds 20% of the original size or holes appear, the screen mesh should be replaced in a timely manner. When replacing, a specialized screen mesh of the same model and aperture should be selected to ensure screening accuracy.

3. Lubrication and maintenance: suitable for harsh environments in garbage disposal

Core component lubrication: The vibration motor bearings are the focus of lubrication. Lithium based grease should be replenished every 500 hours of operation, and the grease should be completely replaced every 2000 hours. When replacing, residual impurities inside the bearings should be cleaned to avoid mixing old grease and affecting the lubrication effect. For the hinges and bolts connecting the sieve box, apply anti rust lubricating grease once a month to prevent the components from getting stuck due to garbage corrosion.

Lubrication precautions: In garbage disposal environments with high humidity and dust, it is necessary to use lubricating grease with excellent waterproof and dustproof properties to avoid water and dust from mixing into the lubricated parts and causing wear and tear; When adding lubricating grease, the amount should be controlled. Excessive lubrication can easily adsorb dust and form oil sludge, which in turn exacerbates component wear; If dealing with corrosive waste, it is necessary to shorten the lubrication cycle by 30% and regularly inspect the lubrication parts for signs of corrosion.

Common fault handling and maintenance safety

Typical fault solutions

1. Low screening efficiency, incomplete garbage classification, clogged screen, abnormal vibration frequency, uneven feeding, cleaning of screen blockages; Calibrate the motor phase angle and adjust the vibration frequency; Optimize the feeder speed and install a material separation device.

2. The equipment vibrates violently, produces excessive noise, causes deformation of the shock absorber spring, looseness of motor bolts, and imbalance of the screen mesh. Replace the shock absorber spring; Tighten the motor and frame bolts; Balance and adjust the screen mesh to remove locally accumulated garbage.

3. Motor overheating tripping, overload operation, poor bearing lubrication, blocked heat dissipation channels, reducing feed volume, cleaning screen blockage; Supplement or replace bearing lubricating grease; Clean the dust from the motor cooling fins.

4. The screen mesh is frequently damaged, the garbage contains large hard objects, the screen mesh material is not suitable, and the installation is loose. Install a pre screening device to remove hard objects; Replace wear-resistant screen mesh (such as high manganese steel material); Re tighten the bolts of the screen frame.

Maintain safety regulations: All maintenance operations must be carried out after the equipment is shut down and the power is cut off, with a "Do Not Close" sign hung to prevent misoperation; When cleaning sticky or corrosive garbage, protective gloves, masks, and goggles should be worn to avoid skin contact or inhalation of harmful substances; When working at heights (such as inspecting the top of the sieve box), it is necessary to fasten a safety belt. When dismantling heavy components (such as motors and sieves), lifting tools should be used to avoid injury during manual handling; The replaced waste screens, lubricating grease, and other waste materials must be classified and disposed of according to environmental protection requirements and cannot be discarded at will.

The vibrating screen, with its precise vibration transmission and material layering principle, is suitable for the classification needs of various types of garbage. Its dedicated structural design effectively addresses the pain points of complex garbage composition. Daily maintenance should revolve around the three core areas of cleaning, inspection, and lubrication. A full process system should be established to address issues such as screen blockage and component corrosion. Through daily cleaning, periodic component monitoring, and scientific lubrication, the occurrence rate of failures can be significantly reduced. Standardized maintenance not only ensures screening efficiency and accuracy, but also extends equipment lifespan and reduces operating costs. Following the principles and maintenance standards described in this article can provide a solid guarantee for the stable operation of the waste treatment system, and help promote the sustainable development of environmental protection and resource recycling.