As a core equipment in the field of industrial coarse screening, Finger Screen has become the preferred choice for processing large and high hardness materials in industries such as mining, construction, and metallurgy due to its strong load-bearing, wear-resistant, and anti clogging characteristics. Its structural design revolves around the core requirements of "coarse screening and classification, impurity interception", and achieves precise adaptation to complex working conditions through scientific component combination and material selection; And the advantages are mainly reflected in durability, adaptability, economy and other dimensions, completely solving the pain points of traditional screening equipment when processing coarse particle materials. This article will comprehensively analyze the technical value of Finger Screens from two aspects: structural composition and core advantages, combined with industry application cases.

Structure composition of bar screen: scientifically designed to adapt to coarse screening conditions

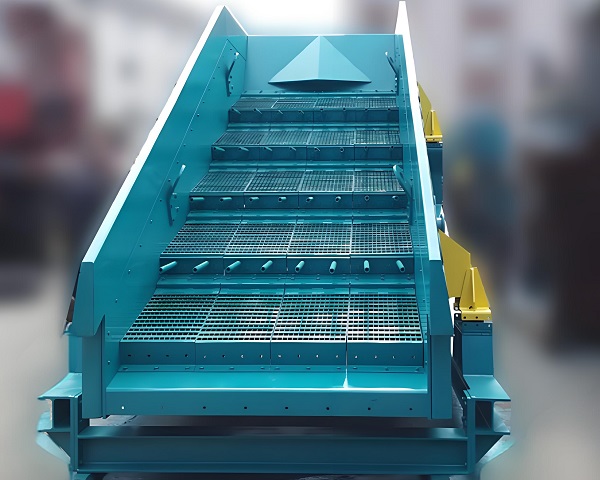

The structure of the Finger Screen is built around three major goals: stable load-bearing, efficient screening, and convenient maintenance. The core consists of four modules: screen surface system, drive system, support system, and cleaning system. Each component works together to ensure effective sorting of large and high hardness materials.

1. Screening system: The core screening component determines the sorting accuracy and durability

The screening surface is the core working component of the bar screen, consisting of parallel arranged metal bars, fixed frames, and gap adjustment devices, which directly contact the material and undertake the dual functions of screening and carrying.

Rod material: Differentiated materials are selected based on the characteristics of the working conditions. In scenarios such as mining and construction where high hardness materials (such as granite and concrete blocks) are processed, high manganese steel (Mn13, Mn18) or wear-resistant alloy steel is used, with a hardness of HRC50-60, strong impact and wear resistance, and a service life that is more than 10 times longer than ordinary carbon steel; For corrosive working conditions such as chemical and metallurgical industries, 316L stainless steel or composite rods coated with polytetrafluoroethylene are selected, which are resistant to acid and alkali corrosion and can operate for a long time in an environment with a pH value of 2-12; High temperature conditions (such as metallurgical slag treatment, temperature above 500 ℃) use 310S heat-resistant steel to ensure structural stability and prevent deformation.

Rod structure: The common "trapezoidal cross-section" design (narrow at the top and wide at the bottom, such as 8mm at the top and 12mm at the bottom) ensures the accuracy of the gap between the rods while increasing the wear-resistant area; Some high-end models use "tungsten carbide spray rods" with a coating thickness of 0.5-1mm, a hardness of HRC60-65, and a 50% increase in wear resistance compared to pure manganese steel. The length of the rod is designed according to the equipment specifications, usually 1.5-6 meters, and the spacing can be adjusted within the range of 20-500mm, suitable for sorting materials of different particle sizes.

Fixed and adjustable device: The bars are fixed to the screen frame by bolts or buckles, making it easy to replace worn bars separately; The gap adjustment device is divided into three modes: manual, electric, and hydraulic. Manual adjustment is achieved by moving the rod position, which is suitable for small and medium-sized equipment; Electric/hydraulic adjustment can be remotely operated through a PLC control system, achieving stepless gap adjustment with a response time of ≤ 30 seconds, suitable for the automation needs of production lines. A certain mining project adopts hydraulic adjustment rod screen, which adjusts the gap in real time according to the fluctuation of raw ore particle size, and improves the screening efficiency by 20%.

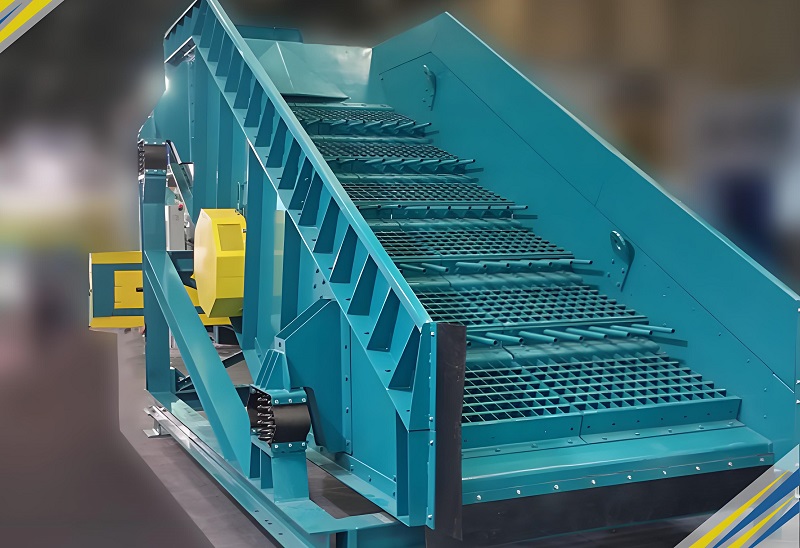

2. Drive system: Provides screening power to ensure operational stability

The drive system provides vibration or swing power for the bar screen, and the core consists of a motor, transmission mechanism, and eccentric block. According to the motion mode, it can be divided into two types: vibration type and swing type:

Vibration driven: The mainstream design scheme uses a vibration motor to directly drive or the motor drives the eccentric block to rotate through a belt or coupling, generating high-frequency vibration (800-1500 times/minute) to make the material jump forward on the screen surface, achieving efficient screening. The vibration motor adopts frequency conversion design, and the speed can be adjusted within the range of 500-1500rpm, adjusting the vibration intensity according to the material characteristics; The weight of the eccentric block can be adjusted by changing the amplitude (1-5mm), increasing the amplitude when handling large materials and decreasing the amplitude when handling fine particles.

Swing Drive: Suitable for handling viscous or easily entangled materials, the crank connecting rod mechanism is driven by a motor to make the screen surface swing back and forth (swing angle 30-60 °), avoiding material adhesion and blockage. The transmission mechanism adopts a sealed design, equipped with wear-resistant bearings and lubrication system, which reduces the intrusion of dust and impurities and extends the service life.

Protection design: The drive system housing adopts dust-proof and waterproof sealing structure, with a protection level of IP65, suitable for harsh environments such as high dust in mines and high humidity in buildings; The motor is equipped with overload protection and thermal relay, which automatically shuts down when the load exceeds 110% of the rated power to avoid motor burnout.

3. Support system: bear the weight of the equipment, absorb vibration and impact

The support system consists of a screen frame, spring support, and base, which bear the weight of the equipment itself and the impact load of materials, while absorbing vibration energy and reducing the impact on the installation foundation:

Screen frame: adopts steel plate welding structure, with a thickness of 8-16mm, and reinforcement ribs are added to key parts to ensure sufficient rigidity and avoid deformation during vibration; The large-scale equipment screening frame adopts a modular design, which is easy to transport and install. It can be disassembled into 2-4 units, and the on-site assembly time is ≤ 4 hours.

Spring support: The core shock-absorbing component is divided into three types: rubber spring, steel spring, and composite spring. Rubber spring has good shock-absorbing effect and low noise, suitable for small and medium-sized equipment; Steel springs have strong load-bearing capacity and long service life, suitable for heavy equipment; Composite springs combine the advantages of both, with a shock absorption rate of over 80%, capable of absorbing 90% of vibration energy, reducing the impact force of equipment on the foundation, and lowering the foundation bearing requirements by 50%.

Base: Made of carbon steel or stainless steel welded together, fixed to the ground with expansion bolts. Large equipment bases are equipped with leveling devices to ensure that the horizontal error during equipment operation is ≤ 0.5%, avoiding material imbalance and uneven screening caused by tilting.

4. Clearing system: prevent material blockage and ensure continuous operation

In response to the problem of sticky and damp materials easily clogging the screen surface, the bar screen is equipped with a dedicated cleaning system. Common designs include:

Mechanical cleaning device: such as elastic scraper and ball cleaning screen, the scraper is in close contact with the surface of the rod and vibrates or swings with the screen surface to scrape off adhered materials; Pinball is installed below the screen surface, and by vibrating and impacting the screen surface, the material blocked in the gap between the bars is shaken off, with a cleaning efficiency of over 90%.

High pressure gas cleaning and blocking: Install high-pressure gas pipes above or below the screen surface, and regularly blow the gaps between the bars with 0.5-0.8MPa high-pressure airflow. This is suitable for handling materials with high dust content and strong viscosity. The blowing cycle can be set by PLC (5-30 minutes/time) without manual intervention.

Heating and blockage removal: For damp materials in low-temperature environments (such as frozen soil and wet coal in winter mines), a heating device is installed inside the screen frame, with a temperature controlled at 5-20 ℃, to prevent material freezing and blockage of the screen surface, ensuring the normal operation of the equipment in winter.

5. Auxiliary system: Enhance equipment functionality and safety

Sealed dust prevention system: adopting a fully sealed cover or partial sealed structure, combined with sealing strips and dust curtains, to reduce dust leakage during screening process, with dust emission concentration ≤ 10mg/m ³, in compliance with national environmental protection standards; The sealing cover adopts a quick release design, which is convenient for equipment maintenance and repair.

Safety protection device: equipped with emergency stop button, protective fence, warning light, meeting industrial safety regulations; Some high-end models are equipped with intelligent monitoring sensors to monitor real-time parameters such as screen frame vibration, motor temperature, and spring deformation. Fault warning is achieved through a PLC system, with an accuracy rate of 95%.

Unloading device: Large blocks of material on the screen and qualified materials below the screen are discharged through different unloading ports, which are equipped with guide plates and conveyor belt interfaces for easy connection with subsequent equipment and continuous production.

The core advantage of bar screen: adapting to the needs of coarse screen and creating multiple values

The advantage of bar screening lies in its scientific structural design and material selection. When processing large, high hardness, and impurity containing materials, it exhibits performance advantages that traditional screening equipment cannot match, providing strong support for enterprises to reduce costs and improve efficiency.

1. Wear resistant, impact resistant, and have a long service life

The core advantage of the bar screen is its strong durability, which is comprehensively strengthened from material to structure according to the material characteristics of coarse screening conditions. Bars made of high manganese steel, wear-resistant alloy steel and other materials can withstand the impact and friction of large blocks of materials (particle size ≥ 500mm). When processing granite with a Mohs grade of 7 or above in mines, the service life of manganese steel bars can reach 1-2 years, while ordinary screens can only be used for 1-2 months; The trapezoidal cross-section and tungsten carbide coating design further enhance wear resistance. Data from a certain metal mine project shows that the annual cost of replacing rods in a tungsten carbide coated rod sieve is only 20000 yuan, which is 75% lower than that of uncoated equipment.

At the same time, the rigid design of the screen frame and support system can resist material impact and avoid equipment deformation. In a construction waste treatment project, the bar screen processes materials containing a large amount of concrete blocks (single block weight ≤ 50kg) daily, and runs continuously for 3 years without significant deformation. The overall service life of the equipment reaches 8-10 years, which is more than 40% longer than traditional vibrating screens (5-6 years).

2. Strong anti blocking ability, ensuring continuous operation

Traditional screening equipment (such as vibrating screens) is prone to clogging of sieve holes when processing viscous, damp, or fibrous materials, requiring frequent shutdowns for cleaning, which affects production efficiency. The bar screen effectively solves this pain point through its unique design:

The bars have a "linear gap" between them, rather than the "pore like structure" of traditional sieves, making it less likely for impurities to get stuck in the gap;

High frequency vibration or reciprocating oscillation causes materials to jump and roll on the screen surface, reducing adhesion;

Real time cleaning of blockage system (scraper, ball, high-pressure gas) to avoid material accumulation.

When processing wet ores with a moisture content of over 20%, ordinary vibrating screens need to be shut down and cleaned every 2 hours, while rod screens can run continuously for more than 12 hours, reducing cleaning frequency by 83%; When dealing with construction waste containing fiber impurities (such as mixed wood chips and plastic ropes), the linear gap of the rod screen can allow fiber impurities to be discharged together with large pieces of material, with a blockage failure rate of only 3%, far lower than the 25% of traditional vibrating screens. After the application of a limestone processing plant, the continuous operation time of the equipment has been extended from 4 hours to 16 hours, and the production line capacity has been increased by 30%.

3. Large processing capacity, high efficiency, suitable for large-scale production

The screening surface area of the bar screen is large (usually 5-20 square meters), the gap between the bars is large, the material screening resistance is small, and the processing capacity is much higher than that of traditional screening equipment of the same specification: a single bar screen can process 200-1000 tons of material per hour, which is 2-5 times that of the vibrating screen of the same specification (50-200 tons/hour). The large-scale open-pit iron mine project uses three bar screens in parallel operation, with a daily processing capacity of up to 40000 tons of raw ore, fully meeting the feeding needs of the subsequent five jaw crushers and ensuring the continuous and efficient operation of the production line.

Stable screening efficiency is another core advantage, which is less affected by material humidity and particle size fluctuations. The pass rate of qualified materials reaches 85% -95%, which is 10 percentage points higher than that of ordinary vibrating screens (75% -85%). After the application of rod screening in a coal washing plant, the pre screening efficiency of raw coal increased by 15%, the processing pressure of the washing process was significantly reduced, and the overall production capacity of the production line increased by 20%.

4. Adjustable gap, strong adaptability, flexible to meet the needs of multiple scenarios

The gap between the bars of the bar screen can be flexibly adjusted within the range of 20-500mm, and it can adapt to the sorting of materials with different particle sizes without changing the screen surface. Its flexibility far exceeds that of ordinary screens with fixed aperture. When processing raw ore from mines, the gap is set to 80-200mm; when processing construction waste, the gap is set to 50-100mm; when processing coal, the gap is set to 50-80mm. One equipment can meet the screening needs of multiple production lines or multiple products.

The adjustment method is convenient and efficient, and manual adjustment is suitable for small and medium-sized equipment. The replacement gap time is ≤ 1 hour; Electric/hydraulic adjustment is suitable for large-scale automated production lines and can be remotely controlled by PLC to achieve rapid gap switching and adapt to fluctuations in incoming material particle size. A certain construction waste treatment plant successfully switched from "coarse aggregate" to "medium aggregate" by adjusting the gap between the bars (from 80mm to 50mm), resulting in a 40% increase in equipment utilization without the need for additional equipment purchase, saving investment costs of over one million yuan.

5. Stable operation, easy maintenance, and reduced overall costs

The bar screen has a simple structure, few moving parts, low failure rate during operation, and significantly lower maintenance costs than traditional screening equipment:

Stable operation: The core moving parts are only the motor, eccentric block, and spring, without complex transmission mechanisms. The operating noise is ≤ 75 decibels, far lower than the vibrating screen (90-100 decibels), and meets industrial noise standards; The vibration energy is absorbed by the spring support, which requires low installation foundation and does not require complex shock absorption devices, reducing installation costs by 40%.

Easy maintenance: Daily maintenance only requires checking rod wear, tightening bolts, and lubricating motor bearings. The maintenance process is simple and does not require professional technicians; The rod is locally worn and can be replaced separately without the need to replace the entire screen surface. The replacement cost is reduced by 60% compared to traditional screens. According to data from a certain mining project, the monthly maintenance time for rod screens is only 2 hours, with an annual maintenance cost of 30000 yuan. However, for vibrating screens with the same processing capacity, the monthly maintenance time is 8 hours, with an annual maintenance cost of 120000 yuan, resulting in a 75% reduction in overall cost.

6. Good environmental friendliness, in line with green production requirements

The design of the bar screen fully considers environmental protection requirements and reduces dust leakage through a sealed dust-proof system. The dust emission concentration is ≤ 10mg/m ³, which complies with the national "Comprehensive Emission Standards for Air Pollutants"; No wastewater or waste residue is generated during operation, no chemical agents are used, and no secondary pollution is caused. In industries with strict environmental requirements such as mining and construction, bar screens can directly meet environmental acceptance standards without the need for additional dust removal equipment, reducing environmental investment costs. After the application of sealed rod screening in a certain mining project, the dust concentration in the workshop decreased from 50mg/m ³ to 8mg/m ³, and the working environment of employees significantly improved, with zero environmental complaints.

The Finger Screen has the core structure of "screen surface system, drive system, support system, and cleaning system". Through scientific material selection and design optimization, it achieves efficient screening of large, high hardness, and impurity containing materials. Its core advantages such as wear resistance, anti clogging, large processing capacity, strong adaptability, easy maintenance, and environmental compliance have completely solved the pain points of traditional screening equipment in coarse screening conditions, becoming the core equipment of mining, construction, metallurgy and other industries. Whether it is reducing production costs, improving production efficiency, meeting environmental requirements, or achieving green production, bar screens can create significant value for enterprises and are the preferred equipment in the field of industrial coarse screening. With the upgrading of industrial intelligence, bar screens will further develop towards intelligent monitoring, automatic adjustment, and remote operation and maintenance, continuously expanding their application boundaries and providing stronger support for cost reduction and efficiency improvement in various industries.