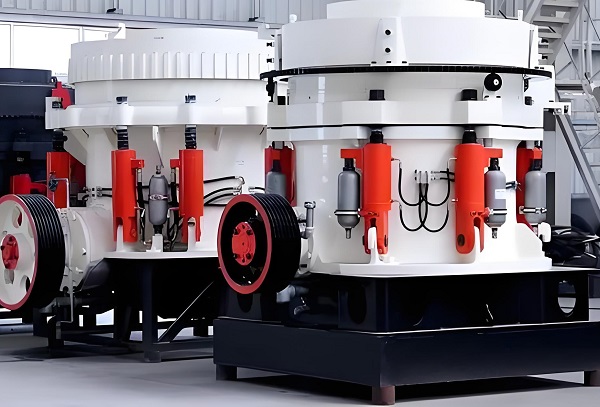

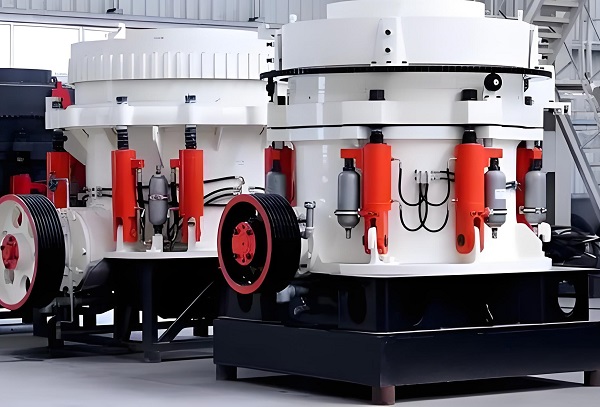

As a technological upgrade of the traditional cone crusher, the hydraulic cone crusher, through the deep integration of its hydraulic system and the principle of layered crushing, demonstrates irreplaceable advantages in the crushing of construction waste (especially mixed waste containing hard materials such as granite and high-strength concrete). It not only inherits the high-efficiency characteristics of the traditional cone crusher's "layered crushing" mechanism, but also achieves precise control of the crushing process, rapid fault handling, and intelligent operation upgrades through hydraulic technology, making it a core piece of equipment for fine crushing of high-hardness materials in large-scale construction waste recycling projects. This article will systematically analyze the structural features and technical advantages of the hydraulic cone crusher, and illustrate its value in practical application scenarios, providing technical reference for high-end recycled aggregate production projects.

A. Core Structure and Working Characteristics of Hydraulic Cone Crusher

The core structure of a hydraulic cone crusher consists of four main modules: the crushing chamber, the hydraulic system, the transmission system, and the intelligent control system. Its working characteristics revolve around "precise controllability, high efficiency and stability, and adaptive adjustment," specifically manifested in the following three points:

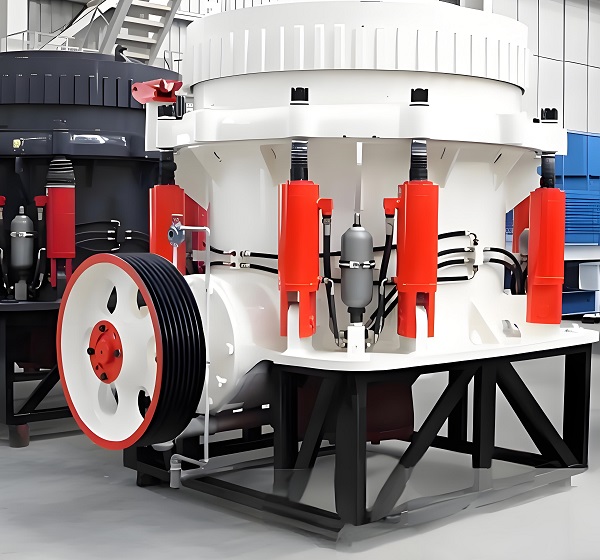

1. Layered Crushing + Hydraulic Adjustment: Precise and Controllable Crushing Process

The hydraulic cone crusher continues the layered crushing structure of "moving cone + fixed cone." Material is subjected to compression and shearing within the crushing chamber, fracturing along natural fissures. The crushing ratio can reach 5-15, further crushing coarse materials below 300mm to high-quality recycled aggregate of 5-25mm. Compared to traditional spring cone crushers, its core upgrade lies in the hydraulic adjustment system: the fixed cone is raised and lowered via a hydraulic cylinder, allowing real-time adjustment of the discharge opening gap. The adjustment range is 3-50mm, with an error controlled within ±0.1mm, precisely matching the production needs of recycled aggregates of different particle sizes. For example, when producing C30 recycled concrete aggregate, the discharge port gap can be stably controlled at 10-20mm to ensure that the content of needle-like and flaky aggregates is <8%; when switching to producing road subbase aggregate, the gap can be quickly adjusted to 20-31.5mm, enabling flexible switching between multiple product specifications.

2. Adaptive Load Adjustment, Outstanding Impact Resistance Addressing the characteristics of mixed composition and large hardness fluctuations in construction waste, the hydraulic cone crusher is equipped with a load adaptive control system. A pressure sensor monitors the material load in the crushing chamber in real time. When encountering large, hard impurities (such as granite fragments or waste reinforced concrete blocks), the hydraulic system automatically increases the crushing force (maximum crushing force can reach over 2000kN) to prevent material jamming; when the material load is too low, the system automatically reduces the crushing force to lower energy consumption. Simultaneously, the equipment has an overload protection function. If encountering unbreakable hard metal blocks, the hydraulic system can quickly depressurize, pushing the fixed cone backward, discharging the impurities, and automatically resetting to prevent equipment damage. Data from a construction waste processing plant shows that production lines equipped with hydraulic cone crushers reduce the material jamming failure rate by 85% compared to traditional equipment, and increase the average mean time between failures (MTBF) to over 4000 hours.

3. Sealed and dustproof design, suitable for harsh working conditions. Construction waste crushing sites have high dust concentrations. The hydraulic cone crusher adopts a double-sealing structure of "labyrinth seal + hydraulic oil seal," effectively preventing dust from entering the transmission and hydraulic systems and protecting core components from wear. The crushing chamber uses wear-resistant liners (made of high-chromium alloy or high-manganese steel), with a hardened surface treatment achieving a hardness of HRC60 or higher, extending service life by 30%-50% compared to traditional liners, making it particularly suitable for long-term processing of high-hardness construction waste. Furthermore, the equipment body adopts a fully enclosed design, combined with a spray dust suppression system, which can control the dust emission concentration at the operating site to below 10mg/m³, meeting environmental emission standards.

B. Key Advantages of Hydraulic Cone Crusher

Compared to traditional cone crushers and impact crushers, hydraulic cone crushers offer significant advantages in crushing efficiency, product quality, operation and maintenance, and overall cost. These advantages can be summarized in the following five points:

1. High Crushing Efficiency and Lower Energy Consumption per Unit

The layered crushing method of the hydraulic cone crusher fully utilizes the material's own weight and compressive force, enabling "multi-particle mutual compression crushing" within the crushing chamber. This results in a 20%-30% increase in crushing efficiency compared to traditional spring cone crushers. Simultaneously, the precise control of the hydraulic system reduces ineffective crushing, resulting in a unit energy consumption (power consumption per ton of material processed) of only 8-12 kW·h, a 15%-20% reduction compared to impact crushers. A comparative test conducted by a large building materials company showed that, when processing high-strength concrete blocks of the same hardness (180MPa), a hydraulic cone crusher can handle 150 tons per hour, while an impact crusher of the same power can only handle 120 tons. Furthermore, it saves 2.5 kWh of energy per ton of material, resulting in annual electricity savings exceeding 300,000 yuan.

2. Superior Product Quality and More Reasonable Grading: The layered crushing principle results in more regular particle shapes after crushing, with a high cubic content (≥90%) and a needle-like/flaky content <8%, far exceeding the requirements of the "Recycled Aggregate for Concrete" (GB/T 25177-2010) standard. Simultaneously, the precise control of the discharge port by the hydraulic system ensures that the aggregate particle size deviation is ≤1mm, resulting in continuous and uniform gradation. This allows for direct use in the production of high-end recycled building materials without the need for additional shaping equipment. For example, a construction waste recycling project used an HPT-500 hydraulic cone crusher, producing 5-25mm recycled aggregate with a crushing value ≤10% and a mud content <0.8%. This successfully replaced natural aggregate in the production of precast components and C40 recycled concrete, achieving a product qualification rate of over 98%.

3. Intelligent Operation, Reduced Labor Intensity Modern hydraulic cone crushers are generally equipped with a PLC intelligent control system and a touchscreen interface, enabling digital adjustment of crushing parameters (discharge gap, crushing force, speed). Operators do not need to manually adjust these parameters on-site; they only need to input the target particle size through the control system for automatic operation. The system also has real-time monitoring capabilities, dynamically displaying equipment operating parameters (oil temperature, oil pressure, load, liner wear) and issuing alarm signals for abnormal conditions (such as overload, excessively high oil temperature, seal failure), facilitating timely troubleshooting. Some high-end equipment also supports remote monitoring and operation, allowing managers to monitor equipment status in real time via mobile phone or computer, achieving unattended operation and significantly reducing labor intensity.

4. Convenient Maintenance and More Efficient Troubleshooting

The hydraulic system of the hydraulic cone crusher integrates a self-diagnostic function, which can quickly locate fault points (such as hydraulic leakage, sensor failure, excessive liner wear), reducing troubleshooting time. The liners adopt a modular design and can be quickly replaced via hydraulic cylinder drive. Replacing a set of liners only takes 4-6 hours, which is more than 50% shorter than traditional cone crushers. In addition, the equipment's lubrication system adopts an automatic oil supply design, which can adjust the oil supply in real time according to the equipment's operating status, avoiding damage to bearings due to insufficient or excessive lubrication and extending bearing life to over 20,000 hours.

5. Lower Overall Cost and Shorter Investment Return Cycle

Although the initial purchase cost of the hydraulic cone crusher is higher (1.2-1.5 times that of a traditional spring cone crusher with the same processing capacity), considering its service life, operating energy consumption, maintenance costs, and other factors, the long-term overall cost is more advantageous. On the one hand, the long lifespan of wear-resistant liners and core components reduces the frequency of replacement of vulnerable parts, lowering annual maintenance costs by 30%-40% compared to traditional equipment. On the other hand, high crushing efficiency and excellent product quality enhance the added value of recycled aggregates, leading to higher sales revenue. A project calculation shows that the investment payback period for hydraulic cone crushers is approximately 1.5-2 years, shortening it by 6-12 months compared to traditional equipment.

C. Applicable Scenarios and Precautions for Hydraulic Cone Crusher

1. Core Applicable Scenarios:

Large-scale construction waste treatment projects (daily processing capacity > 1000 tons), especially suitable for crushing mixed waste containing high-hardness materials (granite, basalt, high-strength concrete);

High-end recycled aggregate production projects, such as recycled concrete, precast components, permeable bricks, and other scenarios with high aggregate quality requirements;

Fixed crushing production lines, serving as the core equipment for medium and fine crushing, forming a complete "coarse crushing + medium and fine crushing + screening" process with jaw crushers and vibrating screens.

2. Precautions for Use

Strictly control the feed particle size to prevent oversized materials (>300mm) from entering the crushing chamber and causing equipment overload.

Regularly check the hydraulic system's sealing performance and replenish hydraulic oil promptly, ensuring hydraulic oil cleanliness (NAS grade ≤ 8) to prevent impurities from entering the system and causing malfunctions.

Select the appropriate liner material and model based on material hardness and crushing requirements; high-chromium alloy liners are preferred for high-hardness materials.

Regularly monitor liner wear; replace liner promptly when wear exceeds 1/3 of the original size to prevent damage to the crushing chamber.

The hydraulic cone crusher, with its core advantages of "high efficiency, precision, intelligence, and environmental friendliness," has become the preferred equipment for crushing high-hardness construction waste and producing high-end recycled aggregates. Its perfect combination of layered crushing principle and hydraulic technology solves the pain points of low crushing efficiency and poor product quality of traditional equipment, while intelligent upgrades reduce operation and maintenance difficulty, providing efficient and stable technical support for large-scale construction waste resource utilization projects. With the continued advancement of policies on the recycling of construction waste and the growth in market demand for recycled building materials, hydraulic cone crushers will develop towards "larger processing capacity, higher intelligence, and lower energy consumption," further expanding their application scope and contributing greater value to the "reduction, harmlessness, and recycling" of construction waste.