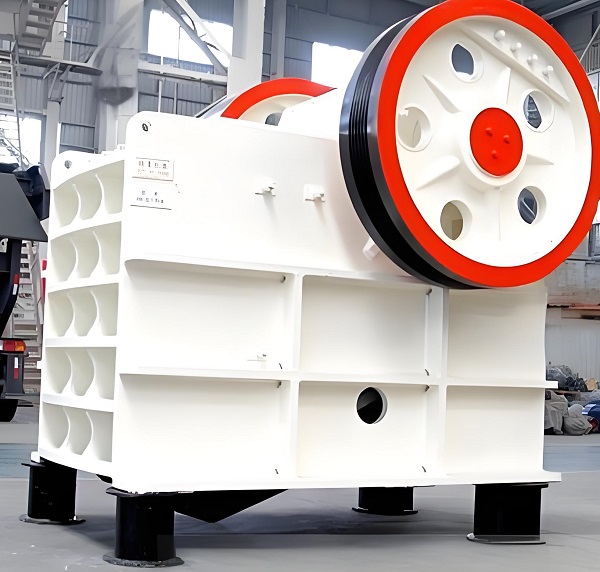

Jaw crushers, as core equipment for coarse crushing operations in industries such as mining, building materials, and metallurgy, are widely used in the crushing and processing of various hard materials due to their simple structure, high reliability, and strong adaptability. Their crushing efficiency directly determines the output capacity of the entire production line, affecting not only production progress but also the company's operating costs and economic benefits. With the increasing demands for efficiency and energy conservation in industrial production, how to systematically improve the crushing efficiency of jaw crushers through scientific methods has become a key issue for companies optimizing their production processes. This article will explain specific methods for improving the crushing efficiency of jaw crushers from multiple dimensions, including equipment selection, feed control, parameter optimization, maintenance, and technological upgrades, combined with practical application cases.

Scientific and reasonable equipment selection is the fundamental prerequisite for improving crushing efficiency. If the equipment model does not match the material characteristics and production needs, subsequent optimization measures will be ineffective. The core of selection lies in accurately matching material parameters with equipment performance. First, it is necessary to clarify the key characteristics of the material to be crushed, including material hardness (such as Protodyakonov hardness coefficient f-value), compressive strength, moisture content, particle size distribution, and impurity content. For materials with high hardness (f>15), such as granite and basalt, a deep-cavity, high-strength jaw crusher should be selected. Its larger moving jaw stroke and stronger crushing force effectively meet the crushing requirements of hard materials. For materials with medium to low hardness (f<10), such as limestone and shale, a conventional jaw crusher can be used, ensuring efficiency while reducing equipment investment costs.

Production scale and output requirements are also important factors in selection. For large-scale continuous production (e.g., hourly output exceeding 500 tons), a large jaw crusher (e.g., PE1200×1500 type) should be selected, along with suitable feeding equipment and conveying systems. If high particle size accuracy is required (e.g., uniformity error ≤5%), a compound pendulum jaw crusher with fine-tuning capabilities should be selected, as its crushing chamber design is more conducive to uniform material crushing. A mining company had previously used an undersized jaw crusher, resulting in an hourly output of only 60% of its design value. After replacing it with a larger, more suitable machine, the output directly increased to the design standard, and the crushing efficiency improved by over 40%, fully demonstrating the importance of accurate equipment selection.

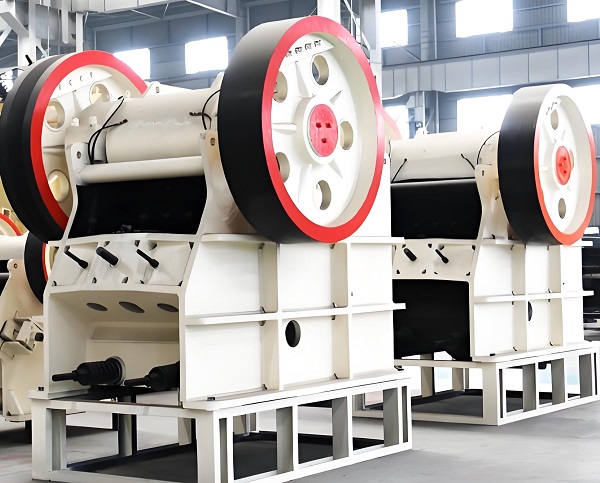

Optimizing the feeding system and material pretreatment is crucial for reducing equipment operating resistance and improving crushing efficiency. The feeding state of a jaw crusher directly affects the load balance of the crushing chamber. Uneven feeding easily leads to "uneven loading," which not only reduces crushing efficiency but also accelerates jaw plate wear. Therefore, a stable feeding device, such as a bar feeder or vibrating feeder, should be added before the crusher. Frequency conversion control allows for precise adjustment of the feed rate, ensuring that the material evenly fills the crushing chamber and that the forces on the moving and fixed jaws remain stable. Simultaneously, a screening pretreatment device (such as the bar screen mentioned above) should be installed at the feed inlet to remove hard impurities such as iron blocks and steel bars from the material in advance, preventing equipment jamming, stalling, and reducing downtime.

Controlling the feed particle size and moisture content can significantly improve crushing efficiency. The feed particle size should be strictly controlled within the maximum allowable feed opening size of the equipment, typically not exceeding 80% of the feed opening width. If there are too many large pieces of material, pre-crushing is necessary to prevent bridging and blockage at the top of the crushing chamber. For materials with high moisture content (e.g., exceeding 15%), adhesion and blockage are prone to occur. This can be addressed by adding a drying device to reduce moisture content, or by using a crushing chamber with an anti-adhesion coating to reduce material accumulation on the chamber walls. In one coal company processing wet coal, material adhesion caused a 30% drop in crusher capacity. By adding a hot air drying device to the feeding system, the crushing efficiency quickly returned to normal levels.

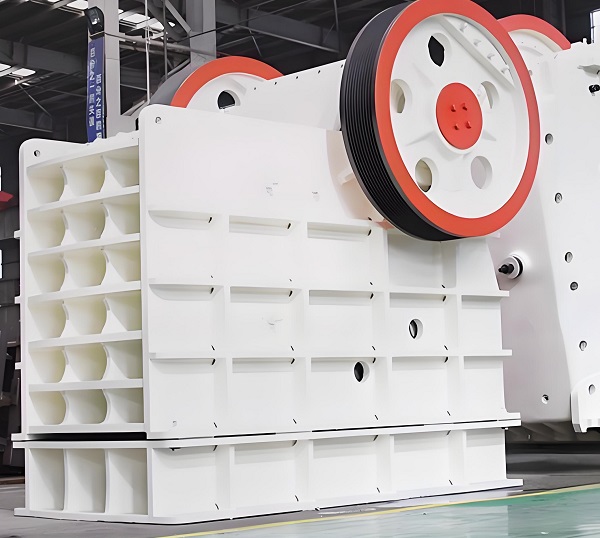

Properly adjusting equipment operating parameters is the core method for unlocking the crushing potential of a jaw crusher. The discharge opening size of the crushing chamber directly determines the output particle size and crushing efficiency, and must be precisely adjusted according to production needs. To ensure the output particle size meets standards, the discharge opening size should be maximized to reduce the number of times the material is crushed within the crushing chamber, thereby increasing processing capacity. If a finer output particle size is required, the discharge opening should be appropriately reduced, but excessively fine discharge should be avoided to prevent overloading the equipment. The discharge opening can be adjusted using the equipment's built-in adjustment device, such as a wedge-type adjustment mechanism. This adjustment process is convenient and efficient, quickly adapting to different production needs.

Optimizing the eccentric shaft speed is also crucial. The eccentric shaft speed directly determines the oscillation frequency of the moving jaw. Excessive speed leads to insufficient material residence time in the crushing chamber, resulting in incomplete crushing and material splashing. Insufficient speed reduces crushing efficiency and fails to fully utilize the crushing chamber's volume. Typically, the eccentric shaft speed for small jaw crushers is 300-500 r/min, while for larger equipment it is 150-300 r/min. In actual production, fine-tuning is necessary based on material characteristics. For example, when crushing hard materials, the speed should be appropriately reduced to extend the crushing time; when crushing medium-soft materials, the speed can be increased to improve processing speed. A limestone processing plant increased its hourly output by 18% by optimizing the eccentric shaft speed from 280 r/min to 320 r/min, while maintaining the same output particle size.

Strengthening daily equipment maintenance and management of vulnerable parts is fundamental to ensuring the continuous and efficient operation of jaw crushers. The wear of vulnerable parts such as jaw plates, liners, and thrust plates directly affects crushing efficiency. Severe wear of the jaw plates can alter the crushing chamber shape, leading to insufficient material crushing and uneven output particle size. Therefore, a comprehensive system for regularly inspecting vulnerable parts is necessary. The wear of the jaw plates should be checked daily, and when the wear exceeds 30% of the original thickness, the jaw plates should be replaced or flipped for reuse (symmetrical jaw plates can be flipped). Furthermore, the material selection for vulnerable parts must be matched to the material characteristics. When crushing hard materials, jaw plates made of high-manganese steel or wear-resistant alloys should be used, as their service life can be 3-5 times that of ordinary steel, reducing the frequency of replacement.

Equipment lubrication and maintenance are also crucial. Poor lubrication of moving parts such as eccentric shaft bearings and connecting rod bearings can lead to increased frictional resistance, reducing equipment speed and potentially causing component burnout. It is essential to regularly add appropriate types of lubricating oil (such as calcium-based or lithium-based grease) to moving parts according to the equipment manual, ensuring sufficient and clean lubrication and unobstructed lubrication. Furthermore, it is necessary to regularly check the fastening bolts, springs, and other components of the equipment; any loosening should be tightened promptly to prevent increased equipment vibration, which can affect crushing efficiency and equipment lifespan. A cement company reduced the equipment failure rate of its jaw crusher from 5 times per month to less than 1 time by establishing a standardized maintenance process, and increased the effective operating rate from 82% to 96%.

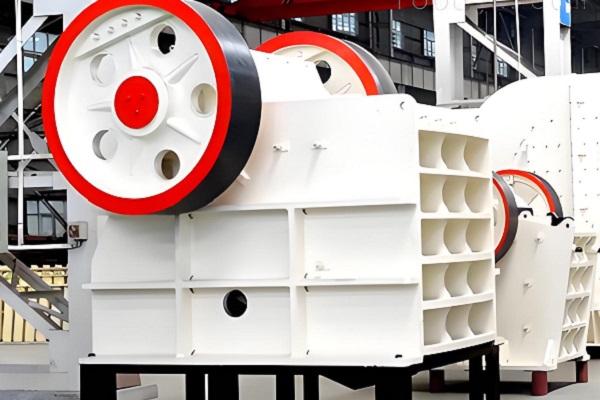

Promoting equipment technology upgrades and intelligent transformation is a crucial path to achieving a leapfrog improvement in the crushing efficiency of jaw crushers. Traditional jaw crushers often rely on manual operation and adjustment, resulting in low parameter control precision and difficulty adapting to complex and changing working conditions. By introducing an intelligent control system, real-time monitoring and automatic adjustment of equipment operating parameters can be achieved. Vibration sensors, pressure sensors, and level sensors are installed on the crusher to collect real-time data on crushing chamber load, vibration frequency, and discharge particle size. This data is then linked to an intelligent control system with the feeder, conveyor belt, and other supporting equipment. When excessive load is detected, the feed rate is automatically reduced; when the discharge particle size exceeds the standard, the discharge port size is automatically adjusted to ensure the equipment is always in optimal operating condition.

Optimized crushing chamber design can also significantly improve crushing efficiency. Traditional deep-cavity crushing chambers suffer from long material crushing paths and are prone to clogging. The new "V"-shaped crushing chamber, through optimized chamber curves, allows for more uniform material distribution within the crushing chamber and more efficient force transmission, increasing crushing efficiency by 15%-20%. Furthermore, using wear-resistant coatings or embedding ceramic liners on the inner wall of the crushing chamber reduces material wear on the chamber walls and extends maintenance cycles. A mining machinery company's intelligent jaw crusher, through the combination of optimized chamber design and an intelligent control system, has reduced unit energy consumption by 25% and increased crushing efficiency by 30%, gaining widespread market recognition.

Optimizing the production process and technological coordination can improve the overall crushing efficiency of jaw crushers. The crushing efficiency of a jaw crusher depends not only on the equipment itself but also on the coordination of upstream and downstream processes. In production line design, it is essential to ensure that the feeding system, screening system, and crusher capacity are matched to avoid equipment idleness due to insufficient feeding or material accumulation due to insufficient subsequent screening capacity. Simultaneously, a "multi-machine linkage" crushing mode can be adopted, connecting multiple jaw crushers in series or parallel. Series operation enables multi-stage crushing of materials, meeting the demand for fine-grained output; parallel operation can significantly increase overall capacity, adapting to large-scale production scenarios.

Improving the professional skills of operators is also a crucial factor in enhancing crushing efficiency. Operators need to be familiar with the equipment's working principles and operating procedures, able to adjust equipment parameters promptly according to material characteristics, and quickly handle equipment malfunctions. Enterprises should conduct regular operator training, covering equipment operation techniques, parameter adjustment methods, fault diagnosis and handling, etc., to improve the professional capabilities of operators. After providing systematic training to its operators, a stone processing plant saw a significant improvement in the precision of its equipment parameter adjustments. Downtime due to operational errors decreased by 70%, and crushing efficiency indirectly increased by 12%.

Improving the crushing efficiency of jaw crushers is a systematic project requiring coordinated efforts across multiple dimensions, including equipment selection, feed control, parameter optimization, maintenance, and technological upgrades. It cannot rely on a single measure. In actual production, companies should develop customized optimization plans based on their material characteristics, production scale, and equipment conditions. This involves focusing not only on improving the performance of the equipment itself but also on the overall coordination of the production process and the training of operators. With the continuous development of intelligent and materials technologies, the crushing efficiency of jaw crushers will see even greater potential for improvement, providing stronger support for the efficient, energy-saving, and green development of industrial production.