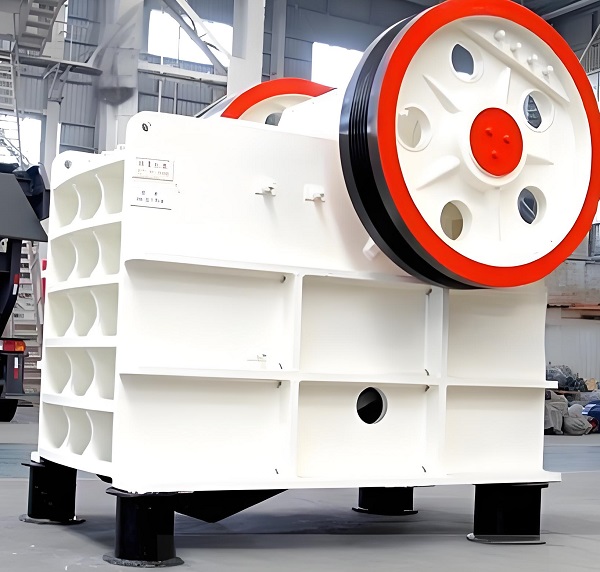

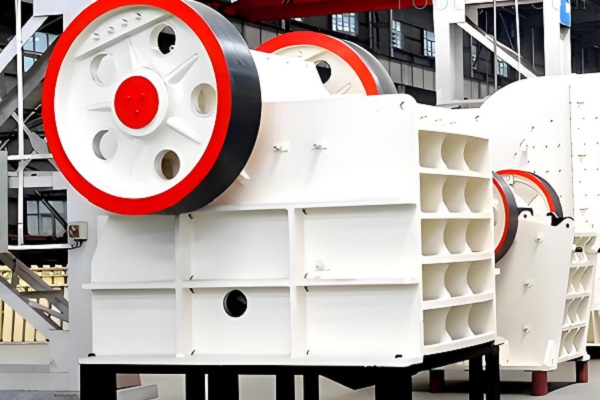

Amidst the global wave of upgrades and iterations in mining crushing equipment, the European-style jaw crusher, with its precise improvements over traditional jaw crushers, has become the mainstream choice for mid-to-high-end crushing production lines. Based on advanced European crushing technology and optimized design considering the material characteristics and production needs of different regions, it achieves breakthroughs in efficiency, energy consumption, and intelligence while retaining the reliability of traditional jaw crushers. Whether in the coarse crushing of hard materials such as granite and basalt, or in large-scale production scenarios in the building materials and metallurgical industries, the European-style jaw crusher demonstrates strong adaptability and competitiveness. A thorough analysis of its structural features and its application advantages compared to traditional models provides important guidance for enterprise equipment selection and production upgrades.

The core competitiveness of the European-style jaw crusher stems from its systematic structural optimization. Through innovative design of key components such as the crushing chamber, transmission system, and support structure, it constructs a highly efficient and stable operating system. In terms of crushing chamber design, it abandons the limitations of the traditional "deep cavity, narrow opening" jaw crusher, adopting a "wide cavity, progressive" chamber structure. The chamber width is increased by 15%-20% compared to traditional equipment of the same specifications, and the ratio of crushing chamber depth to feed inlet is optimized to 1:3.5. This allows materials entering the chamber to quickly form a uniform filling, avoiding the "top bridging" blockage problem common in traditional models. Simultaneously, the chamber curve adopts a multi-segment circular arc transition design, gradually adjusting the crushing angle from the feed inlet to the discharge outlet, making the material more evenly stressed during crushing. The crushing ratio is increased to 6-10, more than 20% higher than traditional jaw crushers, enabling single-pass crushing to meet the particle size requirements before intermediate crushing.

The upgraded transmission system is the power guarantee for the efficient operation of the European-style jaw crusher. It adopts a "dual-motor + V-belt linkage" transmission method, which provides more stable power output compared to traditional single-motor transmission. It can automatically adjust the load distribution according to the material hardness, avoiding motor burnout due to instantaneous overload. The eccentric shaft, as the core component of the transmission, is made of 42CrMo alloy steel through a heat treatment process, achieving a surface hardness of HRC55 or higher. Combined with precision-machined rolling bearings, the eccentric shaft's rotational speed fluctuation is controlled within ±2 r/min. Simultaneously, the transmission system incorporates an elastic damping device, using natural rubber damping blocks to absorb vibration energy during transmission. This not only reduces operating noise but also increases transmission efficiency to 92%, reducing power loss by 5% compared to traditional models.

Regarding the support and adjustment structure, the European-style jaw crusher demonstrates greater practicality and convenience. It employs a dual adjustment mechanism of "hydraulic + wedge" to control the discharge opening size. While traditional jaw crushers require manual adjustment by prying the wedges, the European-style model allows for remote and precise adjustment of the discharge opening via a hydraulic system. The adjustment range ranges from 10mm to 150mm, with an adjustment accuracy of ±1mm, enabling rapid adaptation to different discharge particle size requirements. The support frame adopts an integral welded structure, annealed to eliminate welding stress. The thickness of the frame side plates is increased to 30-50mm, and with the optimized arrangement of reinforcing ribs, the frame's deformation resistance is improved by 40%, enabling it to withstand the enormous forces generated by the impact of hard materials. Furthermore, an adjustable shock-absorbing base is added to the bottom of the equipment. Adjusting the base bolts allows for quick calibration of the screen surface level, reducing overall vibration during operation.

Optimized sealing and dustproof structures are crucial for the European-style jaw crusher's adaptability to complex working conditions. Traditional jaw crushers have poor sealing performance at the connection between the crushing chamber and the transmission system, easily leading to dust entering moving parts and causing wear. The European-style model uses a "labyrinth-type + lip seal" double sealing structure, forming multiple sealing barriers between the crushing chamber and the bearing housing, achieving a dust protection efficiency of over 98%. Simultaneously, the equipment is equipped with an independent dust cover and negative pressure dust removal interface, allowing seamless integration with the production line's dust removal system, keeping the dust concentration during operation below 10mg/m³, meeting national environmental protection standards. In scenarios involving wet materials, the sealed structure effectively prevents moisture from entering the bearings, reducing the risk of component corrosion.

The unique structural design gives the European-style jaw crusher many core application advantages, primarily reflected in a significant improvement in crushing efficiency and processing capacity. The wide-cavity structure and optimized eccentric shaft speed (350-550 r/min for small models, 180-320 r/min for large models) form a perfect match, allowing for a more reasonable residence time of material within the crushing chamber, ensuring both thorough crushing and increased throughput. Application data from a mining company shows that when processing granite, the PEX1000×1200 European-style jaw crusher of the same specifications increases hourly output by 35% compared to traditional models, from 280 tons/hour to 378 tons/hour, while improving the uniformity of output particle size by 25% and reducing the proportion of substandard material from 12% to 9%.

Low energy consumption and controllable operating costs are key factors contributing to the widespread popularity of the European-style jaw crusher among enterprises. Its highly efficient power transmission system and optimized cavity design reduce unit crushing energy consumption by 18%-25% compared to traditional jaw crushers. Taking basalt with a compressive strength of 150MPa as an example, the European-style jaw crusher consumes 0.8 kWh/ton, while the traditional model requires 1.1 kWh/ton. Based on 16 hours of daily operation and an annual output of 300,000 tons of material, this translates to annual electricity savings of approximately 198,000 yuan. Simultaneously, the service life of vulnerable parts is significantly extended. The jaw plates, made of high-manganese steel ZGMn13Cr2 and surface-hardened to a hardness of HRC58 or higher, can last 8-12 months when handling hard materials, 2-3 times longer than traditional jaw plates, significantly reducing the frequency of replacement and procurement costs of vulnerable parts.

Strong adaptability and stable reliability are the core advantages of the European-style jaw crusher in handling complex working conditions. It can adapt to the crushing needs of materials with different hardness (Protodyakonov hardness coefficient f=5-20) and different moisture content (moisture content ≤20%), maintaining stable crushing performance whether it is dry, hard ore in arid regions or wet, sticky materials in rainy southern regions. In high-altitude areas above 2000 meters, through modifications to the motor for high-altitude adaptability, the European-style jaw crusher can operate normally without power attenuation. A non-ferrous metal mine used a European-style jaw crusher at an altitude of 2800 meters, and the equipment operated continuously for 300 days without major malfunctions, maintaining an effective operating rate of over 96%, far exceeding the 85% of traditional models.

The intelligent and convenient maintenance features further enhance the application value of the European-style jaw crusher. Modern European-style jaw crushers are generally equipped with intelligent control systems, which collect real-time operating data such as load, temperature, and vibration frequency through sensors installed in the crushing chamber, motor, and bearings, and display this data intuitively on the central control screen. When the bearing temperature exceeds 75℃ or the load exceeds 110% of the rated value, the system will automatically issue an audible and visual alarm and activate the overload protection program, reducing the motor speed or stopping the feeding to prevent equipment damage. Some high-end models also support remote monitoring and fault diagnosis. Technicians can view the equipment's operating status in real time via mobile phone or computer and remotely guide on-site personnel for maintenance, reducing troubleshooting time from the traditional 4 hours to less than 1 hour.

The improved ease of maintenance is reflected in the user-friendly design of the equipment structure. The European-style jaw crusher adopts a modular disassembly structure. Vulnerable parts such as jaw plates and liners are fixed with high-strength bolts, allowing for quick replacement without disassembling the entire machine using specialized tools, reducing replacement time by 60% compared to traditional models. The equipment's lubrication system uses a centralized lubrication design, allowing multiple moving parts such as eccentric shaft bearings and connecting rod bearings to be lubricated through a single lubrication station. Equipped with an oil level monitoring and filtration device, it can monitor the lubricating oil quality in real time, preventing component wear caused by poor lubrication. Furthermore, the equipment's maintenance door uses a hydraulic opening mechanism; operators can simply press a button to open the door, facilitating cleaning and inspection of the crushing chamber.

Excellent environmental performance is a key aspect of the European-style jaw crusher's alignment with modern industrial development trends. In addition to its highly efficient dustproof sealing structure, its motors primarily utilize variable frequency motors that meet national level-two energy efficiency standards, automatically adjusting speed to avoid unnecessary energy consumption during load fluctuations. The noise level during operation is double-treated with vibration damping devices and a soundproof enclosure, keeping it below 80dB, significantly lower than the 95dB of traditional jaw crushers, effectively improving the working environment. After adopting the European-style jaw crusher in its production line upgrade, a building materials company saw its dust concentration and noise levels at the work site meet national occupational health standards, employee satisfaction increased by 30%, and production stoppages caused by environmental issues were avoided.

In terms of large-scale and customized production, the European-style jaw crusher demonstrates greater flexibility. Manufacturers can offer a full range of products, from small laboratory models (PE150×250) to large production line models (PE1600×2100), tailored to users' production scale, material characteristics, and output requirements. They can also customize special cavity structures, material components, and control systems. For example, to address the crushing needs of wet, sticky materials in the coal industry, anti-adhesion ceramic liners and large-clearance crushing chambers can be customized; for the high-purity requirements of the metal mining industry, non-magnetic stainless steel components can be customized to avoid metal contamination. A large mining company, through a customized European-style jaw crusher production line, achieved integrated operations from raw ore crushing to qualified ore, increasing its annual processing capacity to 5 million tons and improving production efficiency by 45% compared to traditional production lines.

Compared to traditional jaw crushers, the European-style jaw crusher also offers advantages in long-term operational cost-effectiveness. Although the initial purchase cost of European-style jaw crushers is 10%-20% higher than traditional models, considering factors such as reduced energy consumption, extended lifespan of vulnerable parts, and reduced downtime due to malfunctions, the investment payback period can typically be shortened to 1.5-2 years, while traditional models require 3-4 years. Research data from a third-party organization shows that companies using European-style jaw crushers experience an average reduction of 22% in their overall operating costs for crushing processes, with energy costs decreasing by 8 percentage points and maintenance costs by 10 percentage points, fully demonstrating their long-term economic value.

The structural features and application advantages of European-style jaw crushers form a complementary and organic whole. Structural innovations such as wide cavity design, high-efficiency transmission, and intelligent control directly translate into application advantages such as high efficiency, low energy consumption, easy maintenance, and environmental friendliness. In the current context of industrial production transitioning towards high efficiency, energy conservation, and environmental protection, European-style jaw crushers not only meet the core needs of enterprises to improve production efficiency but also align with the era's requirements for green development. With the continuous integration of materials technology and intelligent control technology, the European-style jaw crusher will achieve new breakthroughs in structural optimization and functional upgrades, providing stronger equipment support for the high-quality development of industries such as mining, building materials, and metallurgy, and becoming the mainstream development direction of the future crushing equipment market.