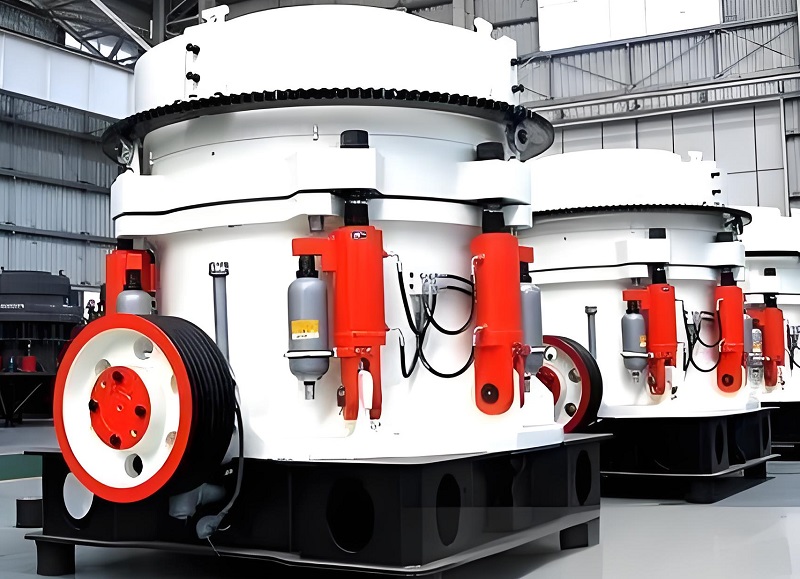

The European-style cone crusher, as a core piece of equipment for fine crushing operations in mining, construction, and metallurgical industries, is widely used in the processing of hard materials such as basalt and granite, thanks to its advantages of high efficiency, energy saving, large crushing ratio, and uniform product particle shape. Its installation quality directly determines the equipment's operational stability and service life. Scientific and standardized maintenance can significantly reduce the failure rate and improve production efficiency. This article, combining the equipment's structural characteristics and on-site practical experience, elaborates on its installation process, key points, and maintenance strategies, providing comprehensive technical guidance for on-site operations to ensure the long-term safe and efficient operation of the equipment.

Installation Process and Key Points of the European-style Cone Crusher

Equipment installation must follow the core principles of "qualified foundation, precise positioning, standardized assembly, and successful trial run," controlling details throughout the process to avoid installation deviations that may lead to future malfunctions. The installation is divided into three stages: preliminary preparation, core installation, and trial run. Each stage is closely interconnected and strictly standardized.

1. Pre-installation Preparation

First, inventory and inspect the components. Check the quantity and integrity of the main machine, motor, hydraulic system, lubrication system, crushing chamber liners, and other components against the packing list. Check for any damage or deformation from transportation, ensure the seals are intact, and that all bolts and other fasteners are complete. If any damage or missing parts are found, contact the manufacturer immediately for resolution. The use of unqualified parts is strictly prohibited.

Secondly, complete the foundation pouring and curing. The equipment vibrates strongly during operation, so the foundation must have sufficient strength and stability. The foundation weight is usually 8-10 times the weight of the equipment, the foundation depth should be greater than the local frost depth, and it should be compacted to prevent settlement. Strictly follow the foundation drawings, reserving positions for anchor bolts and discharge chutes. The foundation surface flatness deviation should be controlled within the specified range. After pouring, cure for more than 28 days to ensure sufficient strength.

Finally, prepare the site layout. Clear debris from the installation site, plan the lifting route and operating space, and equip the necessary tools such as cranes, levels, and torque wrenches. Simultaneously, provide safety training to the installation personnel, clarifying the procedures and precautions to prevent improper operation.

2. Core Installation Steps

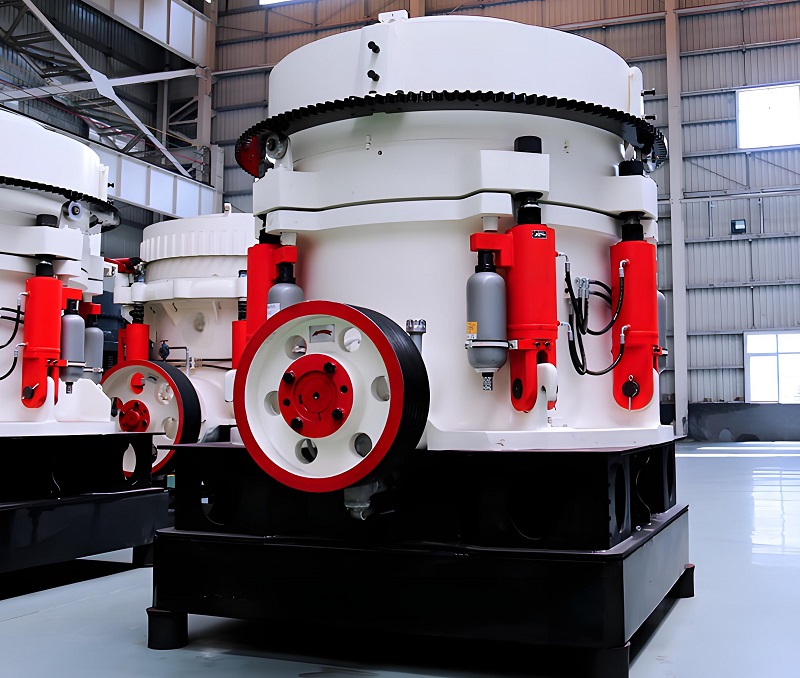

a. Main Machine Installation: Use a crane to lift the main machine onto the foundation. Adjust the position so that the center line of the main machine coincides with the center line of the foundation, with a deviation of no more than 2mm. By adjusting the shims to correct the levelness, the annular machined surface of the main machine base is checked with a level gauge. The levelness deviation should be ≤0.5mm/m. Then, the anchor bolts are tightened, and secondary grouting is performed using high-strength cement mortar to ensure no gaps. After the grouting layer hardens, the bolts are tightened again, the shims are removed, and the gaps are filled with cement.

b. Crushing chamber installation: Clean the debris inside the crushing chamber, remove the anti-rust layer and burrs from the surface of the crushing wall (moving cone liner) and the grinding wall (fixed cone liner). Fix the grinding wall to the adjustment ring and the crushing wall to the moving cone, and tighten the bolts to the specified torque to prevent loosening and detachment during operation. After installation, calibrate the crushing chamber gap. The medium crushing gap should be controlled at 5-15mm, and the fine crushing gap at 3-8mm, ensuring uniform gap and meeting the finished product particle size requirements.

c. Transmission and auxiliary system installation: Hoist the motor to the designated position, adjust the height and position so that the motor pulley and the main machine groove wheel are parallel and aligned. The V-belt tension should be moderate, avoiding excessive tension that increases the motor load and excessive looseness that causes transmission slippage; check the coupling coaxiality, the deviation should be ≤0.05mm, to reduce transmission vibration. Simultaneously install the lubrication system, clean the oil tank and oil pipes, add lubricating oil that meets the standards, and check whether the oil circuit is unobstructed; install the hydraulic system, check the sealing performance to prevent oil leakage, and debug the flexibility of the hydraulic valve.

3. Post-installation trial run

The trial run is crucial for verifying the installation quality and consists of two steps: no-load and load trial runs. The no-load trial run lasts 2-4 hours. After starting the equipment, check whether the motor and main machine are running normally, whether there is any abnormal vibration, whether the oil pressure and oil temperature of the lubrication system meet the standards (oil temperature ≤60℃), and whether there is any leakage at each sealing part. The load trial run requires gradual feeding. First, add a small amount of material, observe the equipment's operating status, and only gradually increase the load to the rated output after confirming that there are no abnormalities. This should continue for 8-12 hours. Check the particle size of the crushed material, equipment vibration, and bolt tightening. If any problems are found, stop the machine immediately for treatment. Only after the trial run is successful can the equipment be put into formal production.

Daily Maintenance and Regular Servicing of European-style Cone Crushers

Equipment maintenance follows the principle of "prevention first, combined with treatment," and is divided into daily maintenance and regular servicing. Emphasis is placed on key areas such as lubrication, hydraulics, and the crushing chamber to reduce potential faults and extend the equipment's service life.

1. Daily Maintenance (Before and after daily operation)

Before starting the machine each day, check the equipment's appearance for damage, and check for loose bolts and nuts, paying particular attention to the fixing bolts of the crushing wall and mantle. Check the oil level and quality of the lubrication system; if the oil level is insufficient, replenish it immediately; if the oil is cloudy, replace it immediately. Check if the hydraulic system pressure is normal and if there are any oil leaks. Clean any residual material from the crushing chamber to prevent jamming after startup.

During operation, monitor the equipment's operating status in real time, observing the motor current, oil temperature, and vibration. Listen to the equipment's operating sound; if any abnormalities occur, stop the machine immediately for inspection. Control the feed size, strictly prohibiting the entry of metal, stones, and other hard objects to avoid damaging the liners and the main machine. Regularly clean the equipment surface and surrounding debris to maintain a clean working environment.

After operation, shut down the machine and cut off the power. Clean any residual material from the crushing chamber and discharge chute to prevent material clumping. Check the wear of the liners; if wear is severe, replace them promptly. Clean the lubrication system filter and check for blockages in the oil lines. Lubricate the rotating parts of the equipment and perform thorough cleaning, recording the equipment's operating status.

2. Regular Servicing (Performed in stages)

a. Weekly maintenance: Check the wear of the V-belts; if cracks or aging are present, replace them promptly and adjust the belt tension. Check the wear of the coupling and replace any damaged elastic pads. Clean the hydraulic system filter and check the hydraulic valves and oil pipes for damage. Check the crushing chamber gap and adjust it according to the liner wear to ensure the output particle size meets specifications.

b. Monthly maintenance: Conduct a comprehensive inspection of the lubrication system, replace the lubricating oil (replace after the first 100 hours of operation, then monthly), and clean the oil tank and oil pipes. Check the hydraulic system seals, replace any aged or damaged seals, and replenish the hydraulic oil. Check the wear of the moving cone and fixed cone and adjust the gap. Tighten all bolts and nuts to prevent loosening.

c. Quarterly Maintenance: Disassemble and inspect the crushing chamber and mantle, and replace severely worn liners; check the operation of the eccentric shaft and bearings, and address any wear or looseness promptly, adding grease as needed; check the operating status of the motor and reducer, and test the insulation performance; thoroughly clean the lubrication and hydraulic systems, check for aging or damage to pipelines, and replace them promptly.

Common Fault Handling and Precautions

Based on on-site practical experience, common faults of the European-style cone crusher mainly include unqualified discharge particle size, abnormal equipment vibration, lubrication system failure, and hydraulic system oil leakage. These require targeted treatment, while strictly adhering to safety operating procedures.

1. Common Fault Handling

a. Oversized discharge particle size: This is often due to excessive crushing chamber clearance or severe liner wear. The machine needs to be stopped to adjust the crushing chamber clearance and replace worn liners to ensure the clearance meets production requirements.

b. Abnormal equipment vibration: This may be caused by loose foundation bolts, deviation in the main machine's levelness, unbalanced moving cone, or uneven material distribution. Tighten the foundation bolts, re-level the main machine, check and address moving cone wear, and adjust the feeding method to ensure even material distribution in the crushing chamber.

c. Lubrication system failure: High oil temperature may be due to insufficient oil level, clogged oil lines, or incorrect lubricating oil type. Add lubricating oil, clean the oil lines, and replace with standard lubricating oil; low oil pressure may be due to a damaged oil pump or seal leakage. Repair the oil pump and replace the seals.

d. Hydraulic system oil leakage: This is often due to aging seals, damaged oil pipes, or loose joints. Replace the seals and damaged oil pipes, and tighten the joints to ensure a good seal in the hydraulic system. 2. Safety Operation and Maintenance Precautions

Equipment operators and maintenance personnel must undergo professional training, be familiar with the equipment structure and operating procedures, and strictly adhere to operating regulations; during shutdown for maintenance, the power supply must be cut off, the hydraulic and lubrication systems must be shut down, and a "Do Not Energize, Under Maintenance" sign must be displayed to prevent accidental startup; when replacing parts such as liners and bearings, special tools must be used, and rough handling is strictly prohibited to avoid damaging the equipment; regular comprehensive inspections of the equipment should be conducted, and maintenance records should be established, documenting maintenance content, time, and fault conditions for future traceability and optimization of maintenance plans.

The installation of the European-style cone crusher requires strict control over foundation pouring, precise positioning, standardized assembly, and trial operation to ensure installation quality; daily maintenance and regular servicing should be standardized and meticulous, focusing on critical parts and promptly addressing potential faults. Only through standardized installation and scientific maintenance can the equipment's advantages be fully utilized, operating costs be reduced, and service life extended, providing stable support for production operations.