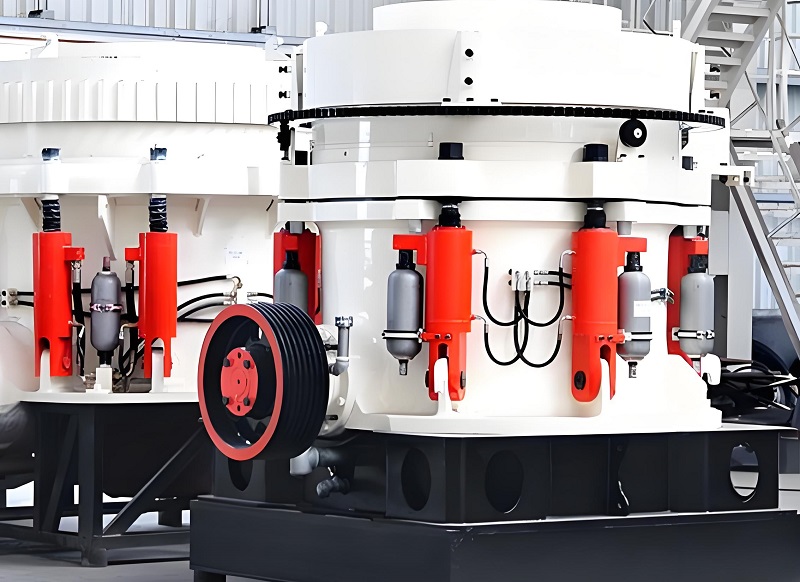

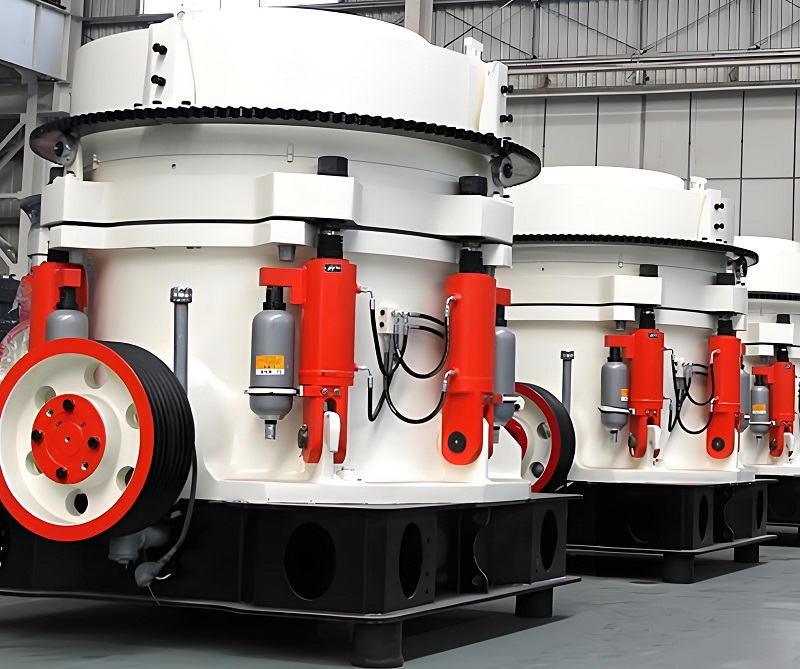

A cone crusher is a high-efficiency crushing equipment designed based on the principle of lamination crushing. With its core advantages of a large crushing ratio, uniform product particle shape, stable operation, and low energy consumption, it is widely used in various industries, including mining, construction aggregate processing, metallurgy, chemical raw material processing, and road and water conservancy engineering construction. As a core fine and medium crushing equipment in the crushing production line, its performance directly determines the efficiency of material crushing, particle size quality, and subsequent processing costs. Different types and specifications of cone crushers are suitable for different types and hardnesses of materials and application scenarios. Accurately understanding their application classification and material compatibility characteristics can effectively improve equipment utilization, optimize production processes, and meet the personalized crushing needs of various industries. This article, based on practical industry experience, elaborates on the application classification of cone crushers, their specific applications in various fields, and the types and characteristics of suitable materials, providing comprehensive technical references for production selection and process planning.

I. Core Applications of Cone Crushers

The core function of a cone crusher is to crush various types of lump materials to the required particle size through compression, shearing, and bending. According to the different crushing stages, it is mainly divided into three uses: medium crushing, fine crushing, and ultra-fine crushing. It can also perform material shaping functions according to industry needs, adapting to the core needs of different production processes and covering all stages from primary crushing of raw materials to fine processing of finished products.

1. Medium Crushing Application: Primary refinement of raw materials, connecting the crushing process

Medium crushing is the most basic and widespread application of cone crushers. It is mainly used to process lump materials after coarse crushing, crushing them to a medium particle size to provide qualified raw materials for subsequent fine crushing stages, while removing impurities from the raw materials and optimizing material uniformity. The core requirement of the medium crushing stage is to balance crushing efficiency and material integrity, avoiding excessive crushing that leads to excessive dust, while ensuring uniform output particle size to meet the feeding requirements of subsequent processing. In the mining industry, the secondary crushing stage primarily processes ore raw materials such as granite, basalt, and limestone after primary crushing by jaw crushers. It reduces the diameter of coarse ore from 500-1000mm to a medium size of 50-150mm, facilitating further processing by subsequent fine crushing equipment. In construction aggregate production, secondary crushing is used to process raw ore or coarse crushed construction waste, removing soil and impurities and reducing particle size, providing a basis for aggregate shaping and grading. In the metallurgical industry, secondary crushing is used to process metal ores such as iron ore and copper ore, crushing the coarse ore to a suitable particle size for subsequent grinding and separation processes, improving mineral recovery rates.

Cone crushers suitable for secondary crushing applications often use a standard crushing chamber, featuring a large feed opening, high processing capacity, and high crushing efficiency. They can handle blocky materials of varying hardness, and offer strong operational stability, allowing for long-term continuous operation to meet large-scale production needs.

2. Fine Crushing Applications: Product Particle Shaping to Meet End-Use Requirements

Fine crushing is a core application of cone crushers, primarily used to further crush materials after secondary crushing to a fine particle size, directly producing finished materials that meet the needs of end-use industries, or providing raw materials for ultra-fine crushing and grinding processes. The core requirements are uniform product particle shape, small particle size deviation, and minimizing material loss during the crushing process to improve the yield of qualified products. Fine crushing applications cover multiple end-use industries, with varying requirements for fine crushing particle size. Equipment of appropriate specifications must be selected based on specific needs. In the construction industry, fine crushing is used to produce concrete aggregates and mortar raw materials, crushing materials to a fine particle size of 5-30mm. 5-10mm is used for mortar preparation, and 10-20mm and 20-30mm are used for concrete pouring. The finished product requires a rounded particle shape and reasonable gradation, without sharp edges, to avoid affecting concrete strength and durability. In road construction, fine crushing is used to produce asphalt mixture aggregates and road base materials, crushing materials to 3-20mm. The finished product requires uniform particle size and high compressive strength to meet the requirements of asphalt pavement laying, improving road flatness and service life. In the chemical industry, fine crushing is used to process chemical raw materials such as gypsum and limestone, crushing them into fine powder or granular form, facilitating subsequent grinding and chemical reactions, and improving the production efficiency and quality of chemical products.

Cone crushers suitable for fine crushing applications often use a short-head crushing chamber, characterized by a large crushing ratio, fine output particle size, and good particle shape. Some equipment is equipped with a hydraulic adjustment device, allowing for flexible adjustment of the output particle size to meet the personalized needs of different end industries. It also utilizes the principle of layered crushing, reducing over-crushing of materials and minimizing dust pollution.

3. Ultra-fine crushing applications: Refined processing, expanding application boundaries

As various industries increasingly demand finer material particle sizes, ultra-fine crushing has become an important expanded application for cone crushers. It is mainly used to crush materials to even finer particle sizes (usually 0.1-5mm), producing fine granular or powdered materials, meeting the needs of high-end building materials, fine chemicals, and deep processing in the mining industry. Ultra-fine crushing requires high precision, stability, and energy efficiency from the equipment, necessitating the use of specialized ultra-fine crushing cone crushers or the modification and upgrading of conventional cone crushers. In the field of mineral processing, ultra-fine crushing is used for the pretreatment of metal ores, further crushing the finely crushed ore to 0.5-5mm. This facilitates subsequent grinding in ball mills, shortens grinding time, and improves mineral separation efficiency and recovery rate, especially suitable for the processing of low-grade ores and finely disseminated minerals. In the high-end building materials field, ultra-fine crushing is used to produce manufactured sand and microcrystalline glass raw materials, crushing materials such as quartz sand and limestone to 0.1-2mm. The resulting manufactured sand has a reasonable gradation and uniform particles, and can replace natural sand in the production of high-end concrete and building decorative materials. In the fine chemical industry, ultra-fine crushing is used to process raw materials such as calcium carbonate and talc, crushing them into ultra-fine particles to facilitate subsequent deep processing and improve the purity and performance of chemical products.

4. Material Shaping Applications: Optimizing Finished Product Quality and Increasing Added Value

In addition to its crushing function, cone crushers can also be used for material shaping, mainly for materials with high requirements for particle shape, such as construction aggregates and road aggregates. By optimizing the crushing chamber structure and crushing parameters, the particle shape of the material is improved, sharp edges are removed, and the finished product has a more reasonable gradation and higher compressive strength, thus increasing the added value of the product.

Material shaping is widely used in the production of high-quality concrete aggregates and asphalt pavement aggregates. For example, key projects such as high-speed railways, expressways, and large bridges have extremely strict requirements on the particle shape and gradation of aggregates. Through the shaping effect of the cone crusher, the needle-like and flaky content of the aggregate can be controlled to below 5%, and the gradation deviation can be controlled within a reasonable range, improving the performance of concrete and asphalt mixtures. In the production of manufactured sand, the shaping effect can improve the particle shape of the manufactured sand, reduce the powder content, and improve the quality of the manufactured sand, making it meet the standards for natural sand.

II. Types and Characteristics of Materials Processed by Cone Crushers

Cone crushers can process a wide range of materials, including rocks, ores, construction waste, and chemical raw materials. The core characteristics of suitable materials are moderate hardness (Mohs hardness 3-12), no strong corrosiveness, and not containing excessive impurities. Different types of cone crushers and crushing parameters are required for materials with different hardness and composition. Based on practical industry applications, the materials processed by cone crushers are divided into four main categories: non-metallic minerals, metallic minerals, construction waste, and other materials. The characteristics, suitability requirements, and processing key points of each type of material are described in detail.

1. Non-metallic minerals: Widely used, highly adaptable

Non-metallic minerals are the main materials processed by cone crushers, including limestone, granite, basalt, quartz sand, marble, dolomite, gypsum, fluorite, etc. The common characteristics of these materials are moderate hardness, no strong corrosiveness, and no metallic impurities. The wear on the equipment's liner during the crushing process is relatively small, making them suitable for various types of cone crushers. They are core raw materials in the construction, building materials, and chemical industries.

a. Limestone: Mohs hardness 3-4, relatively soft and brittle, easy to crush. It is a core raw material for building aggregates, cement, and lime production. When processing limestone, both standard and short-head cone crushers can be used. A standard type can be used in the medium crushing stage, and a short-head type in the fine crushing stage. This results in high crushing efficiency, low energy consumption, uniform product particle shape, and low needle-like and flaky content. During processing, attention should be paid to removing soil impurities from the limestone to avoid affecting product quality, and the crushing speed should be controlled to prevent excessive crushing and the generation of too much powder.

b. Granite, Basalt: Mohs hardness 6-8, hard and wear-resistant. They are high-quality raw materials for high-end building aggregates and road construction, widely used in key projects such as expressways, high-speed railways, and large bridges. These materials require high wear resistance from the equipment, so cone crushers with wear-resistant liners should be selected, preferably hydraulic cone crushers, which have high crushing force and strong wear resistance, effectively improving crushing efficiency and reducing liner wear. During processing, the feed particle size should be controlled, and the mixing of metallic hard objects should be strictly prohibited to avoid damaging the equipment liner and main machine. The crushing gap should also be adjusted to ensure that the finished product particle size meets the requirements.

c. Quartz sand, Fluorite: Mohs hardness 5-7, relatively hard and high purity, mainly used in glass production, fine chemicals, and building materials. When processing these types of materials, fine or ultra-fine cone crushers should be selected. The equipment should have high operating precision and minimize dust pollution. The crushing process should minimize material contamination to ensure product purity. At the same time, wear-resistant liners should be used to prevent liner wear from generating impurities that affect product quality.

d. Gypsum, Dolomite: Mohs hardness 3-5, relatively soft and easy to crush, mainly used in the production of building gypsum, cement additives, chemical raw materials, etc. When processing these materials, a conventional cone crusher is sufficient. It offers high crushing efficiency, low energy consumption, and uniform product particle size. The discharge particle size can be flexibly adjusted according to subsequent processing requirements. During processing, attention should be paid to controlling dust to prevent powder from flying and polluting the environment.

2. Metal Mineral Materials: High hardness, requiring specialized equipment

Cone crushers can process various metal ores, including iron ore, copper ore, lead-zinc ore, manganese ore, gold ore, etc. The common characteristics of these materials are high hardness (Mohs hardness 5-12) and strong wear resistance. Some ores contain impurities, and the crushing process causes significant wear on the equipment. Therefore, a specialized wear-resistant cone crusher should be selected, and the crushing parameters should be optimized to improve crushing efficiency and mineral recovery rate.

a. Iron Ore: Divided into magnetite, hematite, etc., Mohs hardness 6-8, hard texture and strong wear resistance, it is the core raw material for steel production. When processing iron ore, hydraulic cone crushers or multi-cylinder cone crushers are preferred. These devices have high crushing force and strong wear resistance, and can effectively process hard ores. At the same time, the layered crushing principle is adopted to reduce excessive crushing of the ore and improve the mineral recovery rate. In the intermediate crushing stage, the coarsely crushed iron ore is crushed to 50-100mm, and in the fine crushing stage, it is crushed to 10-30mm, providing qualified raw materials for subsequent grinding and separation processes. During processing, gangue impurities in the ore need to be removed to improve the iron ore grade.

b. Copper Ore, Lead-Zinc Ore: Mohs hardness 5-7, relatively hard texture, mostly symbiotic ores, containing a variety of metal components, and are the core raw materials for non-ferrous metal smelting. When processing this type of ore, a fine-crushing cone crusher should be selected, requiring uniform finished particle size to avoid excessive crushing that leads to metal component loss. Wear-resistant liners should also be used to reduce equipment wear. During the crushing process, attention should be paid to the degree of liberation of the ore to ensure effective separation of metal minerals and gangue in the crushed ore particles, improving subsequent sorting efficiency and metal recovery rate.

c. Gold ore, manganese ore: Mohs hardness 4-6, medium texture. Gold ore is mostly finely disseminated minerals, and manganese ore is mostly manganese oxide or manganese carbonate. When processing this type of ore, an ultra-fine crushing cone crusher should be selected to crush the material to 0.5-5mm, facilitating subsequent grinding, cyanidation for gold extraction, or manganese ore sorting, improving mineral recovery rate. During processing, the discharge particle size must be strictly controlled to avoid uneven particle size affecting subsequent processing, and to prevent excessive equipment wear, reducing production costs.

3. Construction Waste: Green Recycling, Achieving Resource Reuse

With the acceleration of urbanization, the production of construction waste is increasing year by year. As a core equipment for the resource utilization and recycling of construction waste, cone crushers can effectively process concrete blocks, bricks, crushed stone, and other materials in construction waste, achieving resource reuse and aligning with the concept of green and environmentally friendly development. The characteristics of construction waste are its complex composition, containing impurities (such as rebar, wood, etc.), and moderate hardness (Mohs hardness 3-6). During the crushing process, impurities must be removed first before crushing.

When processing construction waste, impurities such as rebar, wood, and plastic are first removed through sorting equipment. Then, concrete blocks, bricks, and other materials are sent to a cone crusher for medium and fine crushing, crushing them into aggregates of 5-30mm, which are used to produce recycled concrete, recycled mortar, road base materials, etc. Cone crushers suitable for construction waste processing need to have a large feed opening, strong impact resistance, and good wear resistance. They should be able to handle irregularly shaped materials and be equipped with a hydraulic protection device to prevent impurities from entering the equipment and damaging the main machine. During the processing, dust pollution must be controlled, and dust removal equipment should be installed. Simultaneously, crushing parameters should be optimized to improve the quality of recycled aggregates, ensuring they meet construction standards and achieving the "reduction, resource utilization, and harmless treatment" of construction waste.

4. Other Materials: Adapting to Special Needs and Expanding Application Scenarios

In addition to the three types of materials mentioned above, cone crushers can also process other materials such as coal, coke, slag, and ceramic waste, adapting to the special needs of different industries and expanding the application scope of the equipment. The characteristics of these materials vary considerably, requiring the selection of appropriate cone crusher types and crushing parameters based on the specific material characteristics.

a. Coal and Coke: Mohs hardness 2-4, relatively soft and flammable, mainly used as fuel or raw materials in the power, metallurgical, and chemical industries. When processing these materials, a light-duty cone crusher should be used, requiring no open flames and minimal dust during the crushing process to avoid sparks that could cause safety hazards. The output particle size should also be controlled to ensure it meets combustion or processing requirements.

b. Slag and Ceramic Waste: Mohs hardness 4-6, relatively hard. Slag is a waste product of the metallurgical and power industries, and ceramic waste is a waste product from ceramic production. These materials can be crushed by a cone crusher and used to produce construction aggregates, road base materials, etc., achieving resource utilization of waste materials. Wear-resistant liners should be used during processing to reduce equipment wear, and impurities in the materials should be removed to improve the quality of the finished product.

III. Precautions for Material Handling

When processing materials with a cone crusher, it is necessary to strictly follow relevant operating procedures, taking into account material characteristics, equipment specifications, and production requirements, to ensure crushing efficiency, product quality, and equipment safety. The following points should be given particular attention: First, strictly control the feed size, and strictly prohibit exceeding the maximum feed size specified by the equipment to avoid material jamming, blockage, and damage to the main machine; second, remove impurities from the material, especially hard metal objects, to prevent wear of the liner plates and damage to core components such as the eccentric shaft; third, select the appropriate crushing chamber type and liner plate material according to the material hardness and crushing requirements, optimize crushing parameters, improve crushing efficiency, and reduce equipment wear; fourth, monitor the equipment's operating status in real time during the crushing process, observing the motor current, oil temperature, and vibration. If any abnormalities occur, stop the machine immediately for troubleshooting; fifth, for corrosive materials, use corrosion-resistant equipment or apply anti-corrosion treatment to the equipment to prevent corrosion damage and extend the equipment's service life.

Cone crushers are used for medium crushing, fine crushing, ultra-fine crushing, and material shaping, adapting to the production needs of various industries such as mining, construction, metallurgy, and chemical engineering. They can process a wide range of materials, including non-metallic minerals, etc.