Shredders, as a crucial "pre-processing crushing tool" in the entire waste treatment process, effectively address the pain points of handling various types of waste characterized by "large pieces, stickiness, and mixing" due to their low-speed, high-torque crushing characteristics. Whether it's bulky waste from municipal solid waste, reinforced concrete blocks from construction waste, or clumps of aged waste, shredders can break them down into uniform particle sizes through shearing, compression, and tearing, laying the foundation for subsequent screening, sorting, and resource utilization. Their core value lies in three dimensions: volume reduction and cost reduction, breaking up sticky materials and removing impurities, and adaptability to subsequent processes. They have become a key pre-processing equipment for the "reduction, harmlessness, and resource recovery" of waste. This article will systematically analyze the core role, suitable types, and application cases of shredders in different waste treatment scenarios, providing technical reference for waste treatment projects.

A. The Core Role of Shredders in Municipal Solid Waste Treatment

Municipal solid waste has a complex composition, containing large pieces of waste (furniture, mattresses, cardboard boxes), flexible materials (plastic film, textiles), and mixed debris (kitchen waste + plastic + metal). The core role of shredders is "volume reduction and crushing + pre-treatment to break up clumps," paving the way for subsequent incineration, landfill, or resource recovery.

1. Volume Reduction and Crushing of Large Items of Municipal Solid Waste

Large items such as sofas, mattresses, and wardrobes are bulky and have high transportation costs. Direct landfilling or incineration can easily cause equipment blockage. Shredders can crush these large items into smaller pieces of 50-200mm, reducing their volume by 60%-80%, significantly lowering transportation and disposal costs. For example, a municipal solid waste transfer station in a certain city uses a dual-shaft shredder to process 300 tons of large items of waste per day. The crushed material is compressed before being transported to the incineration plant, reducing the number of transport trips by 70%, lowering the transportation cost per ton by 40 yuan, and saving more than 4 million yuan in transportation costs annually. Meanwhile, the crushed material is easier to mix evenly with other municipal solid waste, improving the combustion efficiency of the incinerator and reducing pollutants from incomplete combustion.

2. Breaking and Separating Flexible Materials Flexible materials such as plastic films, fabrics, and ropes, which are abundant in municipal solid waste, easily entangle with subsequent screening and crushing equipment, causing production line shutdowns. Shredders, through the meshing shearing of dual-shaft or four-shaft cutters, tear flexible materials into short strips or fragments (5-20mm in length), avoiding entanglement problems and simultaneously achieving preliminary separation of flexible materials from other components. A shredder system shredder system in a municipal solid waste incineration power plant breaks down plastic films and fabrics in the mixed waste, and then efficiently separates them using an air separator, increasing the plastic recovery rate to 90%. This not only reduces dioxin generation during incineration but also increases project revenue through plastic recycling.

3. Pre-treatment and Breaking of Kitchen Waste Kitchen waste accounts for 30%-60% of municipal solid waste and easily clumps together. Directly entering the anaerobic fermentation system would affect mass transfer efficiency. Shredders can break down clumps of kitchen waste into uniform particles of 10-30mm, increasing the specific surface area of the material, allowing for full contact between microorganisms and organic matter, shortening the fermentation cycle by 20%-30%, and increasing biogas production by over 15%. A kitchen waste resource recovery project uses a single-shaft shredder for pretreatment, processing 500 tons of kitchen waste per day. After shredding, the material enters an anaerobic digester, achieving a biogas yield of 0.6 m³/kg VS, an increase of 0.1 m³/kg VS compared to unshredded waste, resulting in an annual increase in power generation of over 1 million kWh.

B. The Core Role of Shredders in Construction Waste Treatment

Construction waste includes large concrete blocks, waste bricks and stones, tangled steel bars, waste wood, etc. The core role of shredders is "breaking and separating + volume reduction and adaptation," providing standardized raw materials for recycled aggregate production and resource recovery.

1. Reinforced Concrete Block Demolition and Rebar Separation: Reinforced concrete blocks in demolition waste are hard and structurally robust, making them prone to jamming in traditional crushing equipment, and the rebar is difficult to separate. A twin-shaft shredder, through high-torque shearing, can crush reinforced concrete blocks into small pieces of 50-100mm. During the crushing process, the rebar is sheared into short segments (100-300mm) and discharged along with the aggregate. It can then be efficiently separated and recycled using a magnetic separator. A construction waste treatment plant using a heavy-duty twin-shaft shredder processes 800 tons of reinforced concrete blocks per day. After crushing, approximately 5 tons of waste rebar are recovered daily through magnetic separation, resulting in an annual revenue increase of over 1.8 million yuan. Furthermore, the recycled aggregate has a needle-like and flaky content of less than 10%, making it suitable for direct use in road subbase production.

2. Volume Reduction and Adaptive Crushing of Large Construction Waste: Large construction waste such as waste doors and windows, waste formwork, and waste pipes are irregularly shaped and easily cause blockages at the feed inlet when directly fed into a jaw crusher. Shredders can break waste into uniform block materials (30-80mm), serving as a pre-treatment step for jaw crushers, improving subsequent crushing efficiency by over 30% while reducing jaw plate wear. A mobile construction waste treatment station integrated a shredder with an impact crusher to process waste doors, windows, and formwork on-site. The shredded material directly enters the impact crusher for shaping, achieving a 95% qualified recycled aggregate rate and reducing equipment jamming failure rate by 80%.

C. The Core Role of Shredders in the Treatment of Aged Waste After long-term accumulation, aged waste exhibits severe agglomeration, component adhesion, and the presence of inert substances. The core role of the shredder is "breaking agglomerates + de-adhesion + pre-treatment to separate impurities," clearing obstacles for subsequent screening and resource recovery.

1. Crushing and Disintegrating Agglomerated Materials: After long-term anaerobic fermentation in landfills, aged waste forms hard clumps (particle size can reach over 500mm), containing organic matter, slag, plastics, and other components, which are difficult to separate using traditional screening equipment. Shredders, through low-speed, high-torque crushing, can tear apart the clumps, exposing the internal organic matter and inert substances, creating conditions for subsequent wet screening or air separation. A landfill aged waste excavation and treatment project used a four-shaft shredder, processing 1200 tons of clumped aged waste per day. After crushing, the material underwent wet screening, increasing the organic matter recovery rate to 75%, a 40% improvement compared to uncrushed treatment, significantly improving composting resource utilization efficiency.

2. Breaking Up Sticky Materials: Aged waste has a high moisture content (40%-60%), resulting in severe material adhesion and easy clogging of screening equipment screens. The shearing and compressing action of the shredder's blade shaft can break down the sticky structure of materials, dispersing adhering fine particles and simultaneously shredding tangled plastic films and fabrics, preventing clogging of subsequent equipment. In a certain aged waste resource utilization project, the material processed by the shredder was screened by a bouncing screen, reducing the screen clogging rate from 60% to 10% and increasing screening efficiency by 50%, providing a guarantee for the classified treatment of organic matter composting and inert materials landfill.

D. The Core Role of Shredders in Special Waste Treatment Special wastes such as medical waste, hazardous waste, and electronic waste contain harmful components or have complex structures, requiring special pretreatment. The core role of the shredder is "harmless crushing + resource-based pretreatment," ensuring safe and efficient subsequent disposal.

1.Harmless Crushing of Medical Waste Medical waste (such as waste syringes, waste infusion bottles, and contaminated dressings) contains pathogenic microorganisms and must be disposed of after harmless treatment. The shredder features a fully enclosed design and is equipped with a sterilization device. It can break medical waste into fine particles of 5-10mm, increasing the contact area with disinfectants, improving the sterilization effect, and reducing the risk of leakage during transportation. A medical waste treatment center uses a dedicated explosion-proof shredder, processing 50 tons of medical waste per day. The shredded material undergoes high-temperature sterilization, achieving a 100% harmlessness rate, and the shredding process produces no secondary pollution.

2. Pre-treatment for Electronic Waste Resource Recovery Electronic waste (such as discarded household appliances and circuit boards) contains precious metals such as copper and aluminum, but its complex structure requires shredding for separation and recycling. The shredder can break discarded household appliances into particles of 20-50mm, separating the internal metals from the plastics and circuit boards. The precious metals can then be recovered using magnetic separation, eddy current separation, and other equipment. An electronic waste recycling plant uses a dual-shaft shredder to process 300 used refrigerators, washing machines, and other household appliances daily. The metal recovery rate after shredding reaches 98%, with each appliance yielding approximately 50 yuan worth of recovered precious metals, resulting in an annual revenue increase of over 5 million yuan.

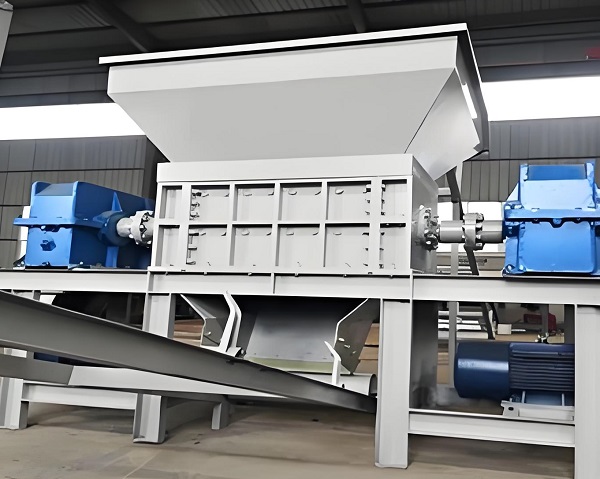

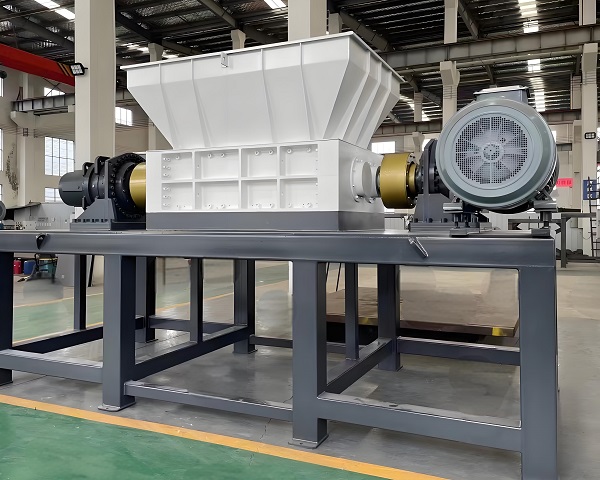

E. Core Technical Characteristics and Adaptation Selection of Shredders

1. Core Technical Characteristics The core advantages of shredders stem from their structural design: First, low speed and high torque, with a typical rotational speed of 5-30 r/min and a torque of 100-500 kN·m, capable of crushing various materials with a hardness ≤200 MPa; Second, the cutter shaft and blade design, with dual or four-axis cutter shafts achieving crushing through meshing shearing, and blades made of high-chromium alloy or hard alloy materials, boasting a service life of 3000-8000 hours; Third, safety protection, equipped with overload protection and automatic reverse function, automatically stopping the machine when encountering uncrushable impurities (such as large pieces of metal) to prevent equipment damage; Fourth, environmentally friendly design, with a fully enclosed body and a spray dust suppression system, achieving a dust emission concentration ≤10 mg/m³, meeting environmental protection requirements.

2. Selection Principles Based on Waste Type

Selection by Waste Type: For municipal solid waste, choose a dual-shaft shredder (suitable for both flexible and lumpy materials); for construction waste, choose a heavy-duty dual-shaft or quadruple-shaft shredder (impact-resistant and wear-resistant); for aged waste, choose a quadruple-shaft shredder (strong agglomeration ability); for medical waste, choose a dedicated explosion-proof sealed shredder.

Selection by Processing Capacity: For daily processing capacity of 100-500 tons, choose a small-to-medium-sized dual-shaft shredder (10-50 tons/hour); for daily processing capacity exceeding 500 tons, choose a large quadruple-shaft shredder (50-200 tons/hour).

Selection by Subsequent Processing: For subsequent incineration or landfill, select a crushing particle size of 50-200mm; for subsequent screening and recycling, select a crushing particle size of 20-80mm; for subsequent composting or anaerobic fermentation, select a crushing particle size of 10-30mm.

Shredders play a crucial role in waste management, spanning the entire chain from pretreatment to volume reduction and adaptation. Whether it's the volume reduction and transportation of municipal solid waste, the recycling of construction waste, the resource-based excavation of aged waste, or the harmless disposal of special waste, shredders are indispensable for pre-processing. By addressing the industry pain points of "large pieces, sticky aggregates, and mixed materials," they not only reduce subsequent processing costs but also improve resource recovery rates and disposal safety, becoming an indispensable key piece of equipment in waste management projects. With the advancement of waste resource utilization policies and technological upgrades, future shredders will develop towards "intelligentization (automatic adjustment of cutter shaft speed, fault warning), multi-functionality (integrated crushing + sorting), and environmental friendliness (low noise, zero leakage)," further expanding their application scenarios in the waste management field and providing more efficient technical support for the construction of "zero-waste cities."