In the industrial shredding and solid waste treatment sectors, twin-shaft shredders have become a mainstream option thanks to their mature technology and wide applicability. Quad-shaft shredders, a recently emerging upgraded model, demonstrate unique advantages in specific scenarios through increased number of shredding shafts and optimized structural design. While both fall under the "multi-shaft shredder" category, significant differences exist in their core structure, shredding principles, performance, and application scenarios, directly impacting equipment selection and performance. This article will analyze the differences between quad-shaft and twin-shaft shredders from five perspectives: structural design, shredding mechanism, performance parameters, application scenarios, and operating costs, providing a professional reference for equipment selection in various industries.

Core Structural Differences: From "Dual-Shaft Linkage" to "Quad-Shaft Synergy"

Structural design is the foundation of shredder performance. The core differences between quad-shaft and twin-shaft shredders lie primarily in the number and layout of shredding shafts, as well as the design of supporting components. These differences directly contribute to differences in shredding capacity and applicable scenarios.

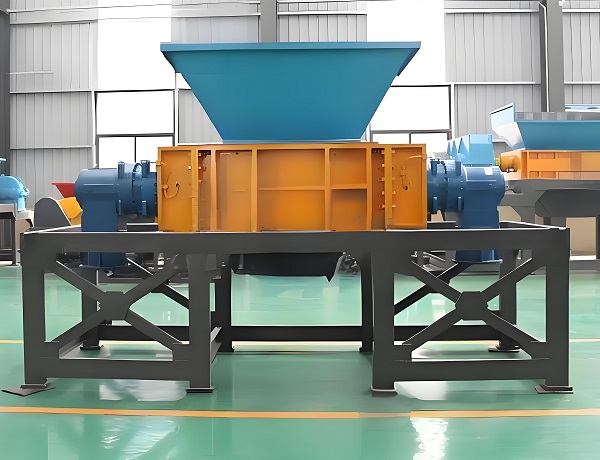

1. Twin-Shaft Shredder: Classic "Parallel Twin Shafts + Interlocking Blade Discs" Structure

The twin-shaft shredder's structure is relatively simple. Its core consists of two horizontally parallel shredder shafts, secured to the frame via bearings. Driven by a reduction motor and gearbox, they rotate synchronously in opposite directions (typically at speeds of 10-60 rpm). Staggered circular blade discs are mounted on each shaft. Made of high-strength alloy steel, these discs are spaced regularly apart by spacers. The blade discs on each shaft interlock—the blade discs of one shaft fit into the gap between the blade discs of the other shaft, creating a "shearing engagement zone."

Twin-shaft shredders are typically equipped with a hydraulic pusher (smaller units may use gravity feed), a discharge screen, and overload protection systems (such as a torque limiter or current monitor). The feed inlet is typically rectangular. A pusher device forces the material into the crushing chamber, where it is crushed by the interlocking action of the two shafts. The crushed material is then screened and discharged from the discharge port. Oversized particles remain in the crushing chamber for further crushing.

This design offers the advantages of simplicity and efficiency, with a concentrated cutter engagement area and crushing force concentrated between the two shafts. It is suitable for processing materials of medium hardness and relatively uniform composition. However, its limitation lies in the limited space in the crushing chamber. For large, tough, or impure materials, shaft entanglement or partial material jamming are common.

2. Four-shaft shredder: A composite structure with two upper and lower sets of two shafts and a staged crushing chamber.

The four-shaft shredder is an upgrade of the two-shaft structure. Its core consists of four crushing shafts, typically divided into an upper and lower set of two shafts, arranged in a two-tiered configuration. (Some equipment uses a horizontal layout with two left and right sets of two shafts, but the mainstream design is a two-tiered design.) Both the upper and lower twin shafts utilize counter-rotating designs, but their speeds and cutterhead structures differ: the upper shafts rotate at a higher speed (typically 30-80 rpm) and feature a wider spacing between the cutterheads, primarily for coarse crushing; the lower shafts rotate at a lower speed (typically 10-40 rpm) and feature a closer spacing between the cutterheads, primarily for fine crushing.

In terms of cutterhead design, the upper shafts of four-shaft shredders typically utilize large-diameter, wide-pitch cutterheads, focusing on tearing and grabbing materials to prevent bulky materials from clogging the feed inlet; the lower shafts utilize small-diameter, close-pitch cutterheads, focusing on fine shearing to ensure uniform discharge particle size. Furthermore, the crushing chamber of a four-shaft shredder utilizes a staged design—a "transition chamber" is formed between the upper and lower shafts. After coarse crushing by the upper shafts, the material enters the transition chamber for temporary storage before further crushing by the lower shafts, avoiding the pressure concentration caused by "one-shot crushing." In terms of supporting components, four-shaft shredders are typically equipped with dual hydraulic pusher systems (one for each shaft), adjustable double-layer screens (the upper screen controls the coarse crushing size, the lower screen controls the fine crushing size), and multi-stage overload protection (each shaft is equipped with a torque limiter). Some high-end four-shaft shredders also feature a "material dispersion device" in the transition chamber to ensure that the coarsely crushed material is evenly distributed into the lower shaft, preventing local overload.

This "upper and lower staged crushing" structure provides a larger crushing chamber and a more consistent crushing process, allowing the four-shaft shredder to handle large and complex materials. However, the structural complexity and manufacturing cost are significantly higher than those of a two-shaft shredder.

Differences in Crushing Mechanisms: From "Single-Bite" to "Graded Crushing"

The difference in structural design directly leads to the fundamental difference in the crushing mechanism between four-shaft shredders and dual-shaft shredders. Dual-shaft shredders rely on "single-bite shearing" to achieve crushing, while four-shaft shredders use a graded crushing mechanism of "coarse crushing + fine crushing" to achieve more efficient and precise crushing.

1. Twin-Shaft Shredder: "Forced Interlock + Triple Action" Single-Pass Crushing

The shredding process in a twin-shaft shredder is concentrated in the interlocking area of the two shafts. Once the material enters the crushing chamber, it is subjected to a triple action of shearing, tearing, and squeezing:

Shearing: As the twin shafts rotate in opposite directions, the interlocking blades exert a shearing force similar to that of scissors, severing the material.

Tearing: For tough materials (such as rubber and plastic film), the teeth of the blades grip the ends of the material and tear it apart through counter-rotation.

Squeezing: The space in the interlocking area gradually shrinks, exerting squeezing pressure on the material, deforming and breaking hard materials (such as metal blocks).

This shredding mechanism is characterized by "single-pass crushing," meaning the material undergoes only one crushing process from feed to discharge. It is suitable for processing materials with medium hardness and low toughness (such as plastic bottles, cans, and wood). However, for materials that are bulky (such as used refrigerator casings), tough (such as used tire carcasses), or contain a lot of impurities (such as mixed household waste), a single crushing operation is difficult to achieve uniform particle size, and it is easy to cause "large chunks not crushed" or "partial over-crushing."

2. Four-Shaft Shredder: "Coarse Shredding Pretreatment + Fine Shredding" for Graded Shredding

The four-shaft shredder's shredding process consists of two stages: coarse shredding and fine shredding. The synergistic action of the upper and lower shafts achieves a progressively finer shredding effect:

Coarse shredding stage (upper shaft): The upper twin shafts rotate at a higher speed and have a larger spacing between the blades. Their primary function is to "grab and initially crush" bulky materials (such as used washing machines and large plastic barrels) using their toothed structure, shredding them into coarse particles of 50-100mm. This also separates impurities (such as copper cores in electrical wiring and metal fragments in household waste) from the material, preventing them from entering and damaging the lower shafts.

Fine crushing stage (lower shaft): After the coarse material enters the transition chamber, it is further crushed by the lower twin shafts. The lower shafts rotate at a lower speed but have a higher torque and a smaller spacing between the blades. Through "fine shearing and squeezing," the coarse material is crushed into fine particles of 10-30mm, ensuring a uniform output particle size. The advantage of this graded shredding mechanism lies in its "step-by-step pressure reduction": coarse crushing first reduces the material's volume and hardness, and fine crushing then controls the particle size, avoiding the "pressure concentration" problem associated with single-stage crushing. For example, when processing scrap automobile frames, the upper set of shafts can tear the frames into 10-20 cm metal blocks, while the lower set of shafts shears them into 5-10 cm metal sheets. The entire process is free of jamming and entanglement, and the crushing efficiency and particle size consistency far exceed those of a dual-shaft shredder.

Performance Parameter Differences: From "Scope of Application" to "Efficiency and Precision"

Due to differences in structure and crushing mechanism, four-shaft and dual-shaft shredders exhibit significant differences in core performance parameters such as material adaptability, processing efficiency, output particle size accuracy, and operational stability. These differences directly determine their respective application scenarios.

1. Material Adaptability: Twin-Shaft "Specialized" vs. Quad-Shaft "All-Rounder"

Twin-shaft shredders: They have moderate material adaptability and are more suitable for processing single-type, medium-hard materials without complex impurities. For example:

Twin-shaft shredders are prone to problems such as material jamming and rapid blade wear when processing materials larger than 1m³ (such as used refrigerators), hard materials (such as cast iron blocks and stone), or mixed materials with a high level of impurities (such as household waste).

Plastics: Plastic bottles, plastic barrels, and plastic film (requires an anti-wrap blade);

Metals: Cans, thin steel plates (thickness ≤ 5mm), and aluminum profiles;

Biomass: Wood (diameter ≤ 30cm), straw, and branches;

Other: Cardboard boxes, paper, and used tires (requires a dedicated blade and can only shred into large pieces). Four-shaft shredders: They have excellent material adaptability and can handle complex materials with diverse material types, high hardness, large volume, and impurities. For example:

The four-shaft shredder's graded crushing design allows it to handle complex materials that are difficult for two-shaft shredders to handle, making it a truly versatile shredder.

Large solid waste: used cars, used home appliances (refrigerators, washing machines), large plastic pallets (volume ≥ 2m³);

High-hardness materials: cast iron blocks (thickness ≤ 10mm), aluminum alloy profiles, construction waste (concrete blocks, bricks);

Mixed materials: household waste (including metals, plastics, and organic matter), electronic waste (circuit boards, wires and cables), and medical waste (including glass, plastics, and metal instruments);

Special materials: used tires (can be directly shredded into 5-10mm rubber particles) and lithium batteries (requires corrosion-resistant blades and a sealed chamber).

2. Processing Efficiency: Dual-Axis "High Efficiency" vs. Quad-Axis "Stability"

Processing efficiency requires a comprehensive assessment of both "hourly throughput" and "effective operating time":

Dual-Axis shredders: When processing suitable materials, they offer higher hourly throughput (0.5-5 tons/hour for small machines, 5-20 tons/hour for medium machines, and 20-50 tons/hour for large machines). However, effective operating time is significantly affected by the material. If the material contains impurities or is too tough, it can easily cause blockage and downtime, typically limiting the effective operating time to 80%-90%. For example, when processing pure plastic bottles, a dual-Axis shredder can achieve a throughput of 8-10 tons/hour. However, if even a small amount of metal is present, the machine will need to be stopped for cleaning, significantly reducing efficiency. Four-shaft shredders offer comparable hourly throughput to two-shaft shredders (0.5-4 tons/hour for small units, 4-18 tons/hour for medium units, and 18-60 tons/hour for large units), but with significantly higher effective operating time (over 95%). This is because: the coarse crushing action of the upper shaft separates impurities early, preventing them from entering the lower shafts; graded crushing reduces the pressure of each individual crushing operation, minimizing the risk of material blockage; and independent overload protection systems on each shaft ensure that any localized problems only require shutdown to address the corresponding shaft, without disrupting the overall process. For example, when processing mixed household waste, a four-shaft shredder can achieve a throughput of 10-12 tons/hour without requiring frequent shutdowns to clean impurities, resulting in significantly higher efficiency and stability than a two-shaft shredder.

3. Output Particle Size Accuracy: Dual-Axis "Adjustable" vs. Quad-Axis "Precise"

The uniformity and controllability of output particle size directly impact the effectiveness of subsequent processing (such as sorting and recycling):

Dual-Axis Shredder: Output particle size can be adjusted by adjusting the blade spacing and screen aperture (adjustable range: 5-50mm). However, particle size uniformity is poor. Due to the limitations of single-pass crushing, some particles are too fine, while others are too coarse. For example, when the blade spacing is adjusted to 10mm to process plastic bottles, the shredded material may contain both 5mm fine particles and 15mm coarse particles, requiring subsequent screening before use.

Quad-Axis Shredder: Using a "double-layer screen + graded crushing" system, precise particle size control is achieved, resulting in a wider output particle size adjustment range (5-100mm) and extremely high uniformity (particle size deviation ≤±2mm). The coarse crushing screen on the upper shaft controls the coarse material particle size, while the fine crushing screen on the lower shaft controls the fine material particle size. This dual screening ensures consistent output particle size. For example, when processing scrap tires, a four-shaft shredder can precisely crush rubber blocks to 8±2mm, allowing them to be directly fed into the grinding equipment for processing into rubber granules without subsequent screening, significantly improving the efficiency of subsequent processes.

4. Operational Stability: Two-Shaft "Basic Protection" vs. Four-Shaft "Multiple Protections"

Operational stability depends on the rationality of the overload protection system and structural design:

Two-shaft shredders: Equipped with basic overload protection (such as a torque limiter and current monitoring), they can handle small amounts of impurities or short-term overloads. However, due to the limited space in the crushing chamber, the accumulation of large impurities or material can easily lead to complete downtime and a lengthy repair process (requiring partial disassembly and cleaning). Four-shaft shredders utilize a "multi-level overload protection + independent shaft control" design. Each shaft is equipped with a torque limiter and current monitor. If the upper shaft encounters impurities, only the upper shaft stops, allowing the lower shaft to continue processing the incoming coarse material. A material dispersion device in the transition chamber prevents material accumulation. Some models also feature an automatic impurity removal function to automatically remove impurities from the crushing chamber. This design reduces the failure rate of four-shaft shredders by over 50%, significantly improving operational stability compared to dual-shaft shredders.

Differences in Application Scenarios: From "Routine Recycling" to "Complex Solid Waste Treatment"

Based on differences in performance parameters, four-shaft and dual-shaft shredders exhibit distinct application areas. Dual-shaft shredders are suitable for routine, single-use recycling applications, while four-shaft shredders specialize in complex, challenging solid waste treatment scenarios.

1. Typical Application Scenarios for Twin-Shaft Shredders

Small and medium-sized resource recycling plants: Processing a single type of waste material, such as plastic recycling plants shredding plastic bottles, metal recycling plants shredding cans, and lumber processing plants shredding waste wood. These applications require a simple material composition and low-precision particle size. Twin-shaft shredders, with their high cost-effectiveness and simple operation, meet these requirements.

Biomass Energy Production: Shredding biomass materials such as straw, corn cobs, and branches to provide feedstock for biomass pellet machines. The twin-shaft shredder's low speed design prevents heating and deterioration of the biomass material, while also providing a processing capacity that meets the needs of small and medium-sized pellet production lines.

Small and medium-sized domestic waste treatment plants: Processing urban household waste (relatively simple in composition and free of large impurities), shredding it for delivery to landfills or incinerators. Twin-shaft shredders offer a lower cost and are suitable for small plants with limited budgets.

2. Typical Application Scenarios for Four-Shaft Shredders

Large solid waste treatment centers: Processing "bulky" waste such as used cars, used appliances, and large plastic pallets. These materials are large and complex (including metals, plastics, rubber, etc.), requiring a four-axis shredder for graded crushing and separation. For example, a car dismantling plant uses a four-axis shredder to break down scrap frames into 5-10cm metal pieces while separating rubber tires and plastic parts, increasing resource recovery rates to over 90%.

Mixed solid waste treatment projects: These processes complex mixed materials such as electronic waste (including circuit boards, wires, and plastic casings), medical waste (including glass, metal instruments, and plastics), and construction waste (including concrete, rebar, and bricks). The four-axis shredder's The "impurity separation + precise particle size control" capability ensures the efficiency of subsequent sorting and recycling. For example, an electronic waste recycling plant uses a four-axis shredder. After shredding, magnetic separation and air separation equipment can separate metals such as copper, iron, and aluminum, achieving a recovery rate of over 95%.

High-end resource recycling projects: These require high output particle size precision, such as waste tire recycling (which requires shredding into uniform rubber blocks for rubber pellets) and lithium battery recycling (which requires shredding to a specific particle size for separating cathode materials). The four-axis shredder's precise particle size control ensures the consistent quality of the recycled products.

Operating Cost Differences: From "Initial Investment" to "Long-Term Consumption"

Equipment operating costs include "initial purchase cost," "energy cost," "maintenance cost," and "labor cost." The differences between four-axis and two-axis shredders in these aspects directly impact a company's return on investment.

1. Initial Purchase Cost: Twin-Shaft "Economical" vs. Quad-Shaft "Expensive"

Twin-shaft shredders: Simple in structure, low in manufacturing cost, and relatively affordable in price—small twin-shaft shredders (with a throughput of 0.5-2 tons/hour) cost approximately 50,000-150,000 RMB, medium-sized units (with a throughput of 2-10 tons/hour) cost approximately 150,000-500,000 RMB, and large units (with a throughput of 10-50 tons/hour) cost approximately 500,000-1.5 million RMB. Four-shaft shredders: Their complex structure requires more shafts, motors, and hydraulic systems, resulting in high manufacturing costs and significantly higher purchase prices than two-shaft shredders. Small four-shaft shredders (with a processing capacity of 0.5-3 tons/hour) cost approximately 100,000-300,000 RMB, medium-sized units (with a processing capacity of 3-18 tons/hour) cost approximately 300,000-1,000,000 RMB, and large units (with a processing capacity of 18-60 tons/hour) cost approximately 1,000,000-3,000,000 RMB.

For businesses with limited budgets and simple processing requirements, a two-shaft shredder offers a more advantageous initial investment. For businesses processing complex materials and seeking long-term efficiency, a four-shaft shredder's higher investment can be offset by its efficient operation and low maintenance costs.

2. Energy Cost: Two-shaft shredders: "Energy Savings" vs. Four-shaft shredders: "Slightly Higher"

Energy costs depend on the equipment's motor power and operating time:

Two-shaft shredders: They have relatively low motor power (5-15kW for small shredders, 15-45kW for medium shredders, and 45-110kW for large shredders). Their energy consumption is stable at low speeds, resulting in approximately 15-25 kWh of energy per ton of material processed.

Four-shaft shredders: They require four shafts and have relatively high motor power (10-25kW for small shredders, 25-75kW for medium shredders, and 75-160kW for large shredders). Their energy consumption per ton of material processed is approximately 20-35 kWh, 20%-30% higher than a two-shaft shredder.

However, it's important to note that four-shaft shredders have a longer operating time and require less frequent downtime for cleaning. Consequently, their "actual energy consumption per unit of time" is significantly lower than that of two-shaft shredders. For example, to process 100 tons of mixed household waste, a twin-shaft shredder needs to run for 12 hours (consuming 2,500 kWh), while a quad-shaft shredder only needs 10 hours (consuming 3,000 kWh). The energy consumption difference is only 20%, but the efficiency is 20% higher.

3. Maintenance Cost: Twin-shaft "High Frequency, Low Cost" vs. Quad-shaft "Low Frequency, High Cost"

Maintenance costs primarily include "blade replacement costs" and "component repair costs":

Twin-shaft shredders: Blades wear more quickly (replace every 3-6 months when processing plastics, and every 1-3 months when processing metals). Each replacement costs approximately 2,000 to 10,000 yuan (depending on the number of blades). Due to the tendency for material blockage, components such as bearings and gearboxes require frequent repairs, resulting in an average annual maintenance cost of approximately 10,000 to 50,000 yuan. Four-shaft shredder: The upper set of blades is primarily for tearing and wears more slowly (replaced every 6-12 months when processing mixed materials). While the lower set of blades wears more quickly (replaced every 3-6 months), individual blades can be replaced independently, eliminating the need for a complete complete shredder. Gradual shredding reduces material blockage, reducing bearing and gearbox maintenance by over 50%, resulting in an average annual maintenance cost of approximately 20,000-80,000 yuan (although higher than a two-shaft shredder, the unit maintenance cost is lower when amortized based on processing volume).

For example, when processing 1,000 tons of mixed materials, a two-shaft shredder requires three blade replacements, costing approximately 30,000 yuan. A four-shaft shredder only requires two blade replacements, costing approximately 40,000 yuan. However, the two-shaft shredder experiences 15 days of downtime, while the four-shaft shredder only experiences 5 days. From a time-to-cost perspective, the four-shaft shredder offers a significant advantage.

4. Labor Cost: Dual-Axis "High Labor Cost" vs. Quad-Axis "Low Labor Cost"

Dual-Axis shredders require dedicated personnel to monitor material feed status in real time to prevent blockages. In the event of a malfunction, two to three people are required to disassemble and clean the shredder, resulting in high labor costs (approximately 50,000 to 100,000 RMB per year).

Quad-Axis shredders are equipped with a PLC automated control system, enabling automatic feeding, shredding, debris removal, and alarms. Regular inspections require only one person. In the event of a malfunction, the independent shaft design facilitates repairs, resulting in lower labor costs (approximately 30,000 to 60,000 RMB per year).

Selection Recommendations: How to Choose the Right Shredder for Your Needs?

The above comparison shows that there's no "superiority" or "inferiority" between dual-axis shredders and quad-axis shredders; they simply differ in their application scenarios. When selecting a shredder, businesses should consider four key factors: material characteristics, processing scale, precision requirements, and budget:

If processing single, medium-hard materials (such as pure plastics or wood), with a processing capacity ≤10 tons/hour, limited budget, and low particle size requirements, a twin-shaft shredder is a more cost-effective option that meets basic shredding needs.

If processing complex, bulky, and impure materials (such as mixed household waste, used cars, and electronic waste), with a processing capacity ≥5 tons/hour, high particle size requirements, and a focus on long-term efficiency, a four-shaft shredder is a better choice. While the initial investment is higher, it improves processing efficiency, reduces long-term costs, and is suitable for complex scenarios.

If processing very small volumes (≤1 ton/hour) for small-scale recycling operations (such as plastic recycling for individual businesses), a small twin-shaft shredder is preferred for its ease of operation and low cost.

If processing specialized materials (such as lithium batteries or medical waste) and meeting environmental and safety requirements, a dedicated four-shaft shredder with corrosion-resistant and leak-proof design is recommended to ensure compliance and safety.

A two-shaft shredder is an economical choice for routine shredding, while a four-shaft shredder is an efficient choice for complex shredding. To maximize the value of your equipment investment, businesses must clearly define their needs and avoid blindly pursuing high-end products or excessively saving costs.