In the fields of industrial solid waste treatment, resource recycling, and environmentally friendly processing, shredding equipment is a key component in achieving material volume reduction and resource reuse. Twin-shaft shredders, with their unique structural design and superior performance, have become a mainstream device for complex material shredding. Compared to similar equipment like single-shaft shredders and hammer crushers, twin-shaft shredders offer significant advantages in material adaptability, shredding efficiency, and operational stability. They are widely used in shredding a variety of materials, including plastics, rubber, metal, wood, and household waste. This article will systematically analyze the core structure of twin-shaft shredders, its technical features, and, based on practical application scenarios, provide an in-depth explanation of their core advantages in industrial production and environmental protection, providing a reference for selecting models in related industries.

Core Structure and Technical Features of Twin-Shaft Shredders

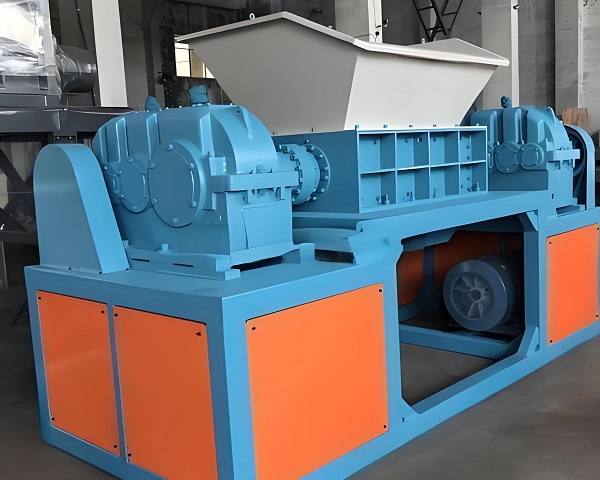

The performance advantages of twin-shaft shredders stem from their scientific structural design. Their core components include two parallel, counter-rotating shredder shafts, a cutterhead assembly, a drive system, a feed mechanism, a discharge mechanism, and a control system. This "dual-shaft linkage" design creates unique technical features that distinguish it from other shredders. These features can be summarized in the following five aspects:

1. "Dual-shaft counter-rotating" design achieves forced feeding and uniform crushing.

The most notable structural feature of a dual-shaft shredder is its use of two horizontally parallel crushing shafts, driven by a drive system to rotate in opposite directions (typically at speeds of 10-60 r/min). The staggered cutterheads and blades on the shafts form a "bite-type" crushing mechanism. When material enters the feed inlet, the counter-rotating shafts generate a powerful traction force, forcing the material into the crushing chamber. This eliminates the "stuck" and "blocked" problems often associated with single-shaft shredders due to the high viscosity and hardness of the material. Furthermore, the counter-rotating cutterheads perform a multi-action "shearing, tearing, and squeezing" action on the material, resulting in uniform material division within the crushing chamber. This results in a more consistent particle size and effectively reduces over- or under-crushing. For example, when processing flexible materials like plastic film, the traction of the dual shafts prevents material entanglement, ensuring a continuous and stable shredding process. When processing scrap metal cans, the interlocking crushing mechanism evenly tears the cans into flakes, facilitating subsequent compaction or melting.

2. Modular Cutterhead and Blade Design: Durability and Maintenance Ease

The cutterhead and blades are the core working components of a dual-shaft shredder, and their design directly impacts shredding efficiency and service life. Currently, mainstream dual-shaft shredders generally utilize a modular cutterhead assembly. The cutterhead is heat-treated from high-strength alloy steel (such as Cr12MoV and 42CrMo), achieving a hardness of HRC55-60 and excellent wear and impact resistance. The blades are bolted to the cutterhead and can be selected in various shapes (e.g., diamond, rectangular, or sharp-toothed) depending on the material's characteristics. For example, thick, wear-resistant blades are used for processing hard materials (e.g., stone or metal blocks), while sharp-toothed tearing blades are used for processing flexible materials (e.g., cloth or paper). The advantages of this modular design are: first, blades can be removed and replaced individually when worn, eliminating the need to replace the entire cutterhead assembly, significantly reducing maintenance costs and downtime. Second, the cutterhead spacing can be adjusted or the blade type can be changed to suit different material shredding requirements, enhancing the equipment's versatility. For example, in a waste tire recycling project, replacing the dedicated "toothed blades" allows the twin-shaft shredder to shred tires into 5-10cm rubber blocks, which are then processed into rubber pellets through a grinding machine. This entire process can be accomplished simply by adjusting components without replacing the main unit.

3. Multi-stage crushing chamber and adjustable output particle size to meet diverse processing needs

The crushing chamber of a twin-shaft shredder typically adopts a "tapered" or "graded" design. From the feed inlet to the discharge outlet, the chamber volume gradually decreases. Combined with the rotation of the twin shafts, this achieves a multi-stage crushing process from coarse crushing to medium crushing to fine crushing. Furthermore, the equipment can precisely control the particle size of the shredded material by adjusting the blade spacing and the aperture of the discharge screen. For example, adjusting the blade spacing to 5mm can shred plastic bottles into fine particles, while adjusting it to 50mm can shred wood into chunks. This adjustability allows it to meet the processing needs of various industries. In household waste processing, shredding materials to 30-50mm facilitates subsequent sorting (such as separating metals, plastics, and organic matter); in the biomass energy sector, shredding straw and branches to 10-20mm improves the pelletizing efficiency of biomass pellet machines; and in the recycling of used home appliances, shredding the outer casing to 20-30mm facilitates the extraction of metals such as copper and iron. In contrast, single-shaft shredders have a narrower output particle size adjustment range, and hammer crushers are prone to over-shredding, making them difficult to meet the needs of various scenarios.

4. Comprehensive overload protection system ensures high operational stability. Industrial shredders often feature complex material compositions (for example, used equipment may contain hard debris such as bolts and rebar). Lack of effective protection mechanisms can easily lead to malfunctions such as cutterhead jamming and motor burnout. The twin-shaft shredder's design takes this into account, featuring multiple overload protection systems. These include: a torque limiter. When the crushing resistance exceeds a set value (e.g., due to hard debris), the torque limiter automatically cuts off power, preventing damage to the cutterhead and motor. A current monitoring system monitors the motor current in real time. If the current exceeds the rated value, the device automatically shuts down and issues an alarm. A hydraulic pusher is included in some large twin-shaft shredders. This mechanism automatically adjusts the push speed based on the amount of material in the crushing chamber, preventing blockage caused by overfeed. It also reverses the push to remove debris in the event of an overload. These protections significantly reduce the failure rate of twin-shaft shredders when handling complex materials and significantly improve operational stability. For example, at an automobile dismantling plant, a twin-shaft shredder, when processing scrap frames, can shut down immediately even if hard components such as bolts and bearings are mixed in. The overload protection system allows the machine to be cleared and resume operation, thus avoiding economic losses caused by equipment damage.

4. Low-speed, high-torque design: balancing efficiency and energy savings

The drive system of a twin-shaft shredder typically utilizes a "reduction motor + gearbox" combination. This, combined with the dual-shaft structure, enables a "low-speed, high-torque" operating mode. Speeds are typically controlled between 10-60 rpm, while torque can reach tens of thousands of Newton-meters. The advantages of this design are: First, high torque ensures the machine's ability to shred hard and tough materials, such as steel plates up to 10mm thick and wood up to 30cm in diameter. Second, low-speed operation reduces vibration and noise (typically below 85dB) and energy consumption. Compared to high-speed hammer crushers, twin-shaft shredders can reduce unit energy consumption by 20%-30%. Taking waste plastic processing as an example, data from one company shows that a twin-shaft shredder consumes approximately 15-20 degrees Celsius to process one ton of PP plastic, while a single-shaft shredder requires 25-30 degrees Celsius and a hammer crusher requires 30-35 degrees Celsius. Furthermore, operating at a low speed reduces frictional heat generated between the cutter head and the material, preventing heat-sensitive materials like plastic and rubber from melting and sticking during the shredding process, thereby improving shredding quality.

Core Advantages of Twin-Shaft Shredders: Practical Value from an Application Perspective

The technical features of twin-shaft shredders give them irreplaceable advantages in industrial production and environmental protection. These advantages are not only reflected in the performance of the equipment itself, but also translate into increased efficiency, cost reduction, and environmental benefits in actual application. Considering different industry applications, its core advantages can be summarized in the following four aspects:

1. Highly adaptable materials, capable of handling diverse and challenging materials

In the field of solid waste treatment and resource recycling, material types are complex and diverse, ranging from hard materials (such as metal, stone, and ceramics) to flexible materials (such as plastic film, cloth, and paper) and tough materials (such as rubber, cable, and wood). The twin-shaft shredder, with its "dual-shaft interlocking shredder + modular blade" design, can handle a wide range of materials, eliminating the need for frequent equipment changes and significantly enhancing production line flexibility. For example, at a waste recycling plant, a dual-shaft shredder can process waste plastic bottles, cans, cartons, and tires in sequence, simply by adjusting the distance between the blades and the cutter disc according to the material type. In electronic waste processing, it can shred used computer cases (plastic + metal), circuit boards (resin + metal), and wires and cables (plastic + copper core). After shredding, these materials are separated through sorting equipment for resource recovery. In agriculture, it can shred biomass materials such as straw, corn cobs, and branches, as well as agricultural waste such as plastic greenhouse film and pesticide bottles, contributing to a "green agricultural cycle." In contrast, single-shaft shredders have limited handling capacity for flexible materials and are prone to entanglement. Hammer crushers are less effective at shredding tough materials (such as rubber and wood) and are prone to rebound or clogging, making them difficult to handle with multiple materials.

2. High shredding efficiency helps increase production line efficiency.

In industrial-scale production, shredding efficiency directly impacts the overall production capacity of the entire production line. The twin-shaft shredder's "forced feed + multi-stage crushing" design enables high processing capacity—small twin-shaft shredders can process 0.5-5 tons per hour, medium-sized units can reach 5-20 tons, and large units (such as those used for construction waste processing) can reach 20-100 tons. This high efficiency is primarily due to two factors: First, the forced feed design eliminates material blockage, ensuring continuous operation and over 90% effective operating time; second, the dual-shaft shredding method simultaneously shears the material in multiple directions, resulting in rapid shredding and a greater volume of material processed per unit time. For example, a plastic recycling project uses a medium-sized twin-shaft shredder to process used plastic barrels, achieving an hourly capacity of 8-10 tons. The shredded plastic blocks are then cleaned and granulated for re-production into plastic products. Compared to traditional single-shaft shredders (which process 3-5 tons per hour), this increases production line capacity by over 60%, resulting in an increase in annual economic benefits of nearly one million yuan. Furthermore, in municipal waste incineration power generation projects, twin-shaft shredders can reduce household waste to a uniform particle size, improving the incinerator's combustion efficiency, reducing harmful gas emissions, and increasing power generation. Data shows that shredded household waste can increase incineration efficiency by 15%-20%, and power generation can increase by 50-80 kWh per ton of waste.

3. Low operating costs, balancing "equipment maintenance" and "energy consumption control"

For businesses, equipment operating costs (including energy consumption, maintenance costs, and labor costs) are a key factor affecting return on investment. Double-shaft shredders have significant advantages in this regard: in terms of energy consumption, the low-speed, high-torque design makes its unit energy consumption much lower than that of single-shaft shredders, hammer crushers and other equipment, and long-term operation can save a lot of electricity bills; in terms of maintenance costs, the modular blade design makes blade replacement more convenient and can be operated without professional technicians, and the blade has a long service life (when processing ordinary plastics, the blade can be used for 3-6 months; when processing metals, it can be used for 1-3 months), which greatly reduces maintenance costs and downtime; in terms of labor costs, the double-shaft shredder has a high degree of automation and is equipped with a PLC control system, which can realize automatic feeding, automatic crushing, automatic overload protection and alarm. It does not require dedicated personnel on duty, only regular inspections are required, which reduces labor input. For example, a large-scale scrap tire recycling company uses two large twin-shaft shredders (with an hourly processing capacity of 15 tons), running eight hours per day. These shredders consume approximately 24,000 kWh of electricity per month. A hammer crusher, on the other hand, would consume 36,000 kWh per month, saving 144,000 yuan annually in electricity costs alone. Furthermore, the twin-shaft shredder blades need to be replaced every three months at a cost of approximately 5,000 yuan per replacement, while the hammer crusher's hammers need to be replaced every month at a cost of approximately 8,000 yuan per replacement. This results in an annual maintenance cost savings of 66,000 yuan.

4. Significant Environmental Benefits, Assisting with "Solid Waste Reduction" and "Resource Recycling"

Driven by the "Dual Carbon" goals and environmental policies, solid waste reduction and resource recycling have become critical tasks for all industries. Through efficient shredding, twin-shaft shredders can achieve both volume reduction and resource utilization, offering significant environmental benefits. Shredding significantly reduces material volume, lowering transportation and storage costs and reducing floor space. For example, shredding can reduce the volume of household waste by 30%-50%, while shredded tires can reduce their volume by 60%-80%. This extends the lifespan of landfills and solid waste treatment plants and reduces environmental pressure. Shredded materials are also easier to sort and recycle, promoting resource recycling. For example, shredded waste plastics can be re-pelletized into new plastic products, reducing "white pollution." Shredded scrap metal can be directly smelted, reducing energy consumption and pollutant emissions. Shredding biomass materials can be made into biomass pellets, replacing fossil fuels and reducing carbon emissions. Taking a municipal waste treatment project as an example, a dual-shaft shredder, sorting equipment, and incineration power generation process is used to separate and recycle recyclable materials such as plastics and metals from household waste. Organic matter is crushed and used for composting, while the remaining material is incinerated to generate power. This results in a waste resource utilization rate exceeding 80%, significantly higher than traditional landfill methods (which have a resource utilization rate of less than 10%). Furthermore, the dual-shaft shredder operates with low noise and dust, and the dust removal and noise reduction devices further minimize environmental impact, meeting environmental protection requirements.

Development Trends and Application Outlook of Twin-Shaft Shredders

With advancements in industrial technology and rising environmental protection demands, twin-shaft shredders are evolving toward intelligence, large-scale development, and specialized applications. Regarding intelligence, future twin-shaft shredders will integrate IoT technology. Sensors will monitor the equipment's operating status (such as blade wear, motor temperature, and material particle size) in real time, and AI algorithms will automatically adjust operating parameters, enabling unmanned operation and predictive maintenance. Regarding large-scale development, twin-shaft shredders with larger processing capacities (over 100 tons per hour) will become mainstream for processing large quantities of solid waste, such as construction waste and used cars, enhancing scalable processing capabilities. Regarding specialization, specialized twin-shaft shredders will be developed for specific materials (such as lithium batteries, medical waste, and hazardous waste), featuring corrosion-resistant and leak-proof features to meet the needs of specific applications. From the perspective of application scenarios, the application scope of the double-shaft shredder will be further expanded: in the field of new energy, it can be used for the crushing and recycling of lithium batteries, separating positive electrode materials, negative electrode materials and metal shells, and promoting the development of the "power battery recycling" industry; in the medical field, it can be used for the harmless treatment of medical waste, through crushing + high-temperature sterilization to avoid virus transmission; in the construction field, it can be used for the crushing and regeneration of construction waste, crushing concrete and bricks into aggregates, and using