Vibrating feeders are indispensable in the production processes of many industries. Their features such as precise feeding, simple structure, low energy consumption, and long service life solve many pain points of traditional feeding equipment and provide strong support for the efficient, stable, and automated operation of industrial production.

As a sorting device that relies on the coordinated operation of airflow and machinery, the service life of an air classifier is affected by many factors, including the suitability of the selected model, the quality of daily maintenance, the wear resistance of components, and the stability of the operating conditions.

The aged waste screening and processing system achieves precise waste sorting and maximizes resource utilization through mechanized and intelligent collaborative operations.

Cone crushers play a crucial role in industrial crushing, assisting in ore processing, aggregate production, waste recycling, and engineering support, thus providing support for multiple industries.

Bar screens play a crucial role in industrial screening, enabling material pretreatment, grading and screening, dewatering and impurity removal, and protection of downstream equipment, thus empowering multiple industries to improve efficiency.

The maintenance of magnetic separators needs to take into account both daily basic inspections and periodic in-depth maintenance, forming a complete system from daily appearance, lubrication and magnetic field inspections to targeted maintenance on a weekly, monthly and annual basis.

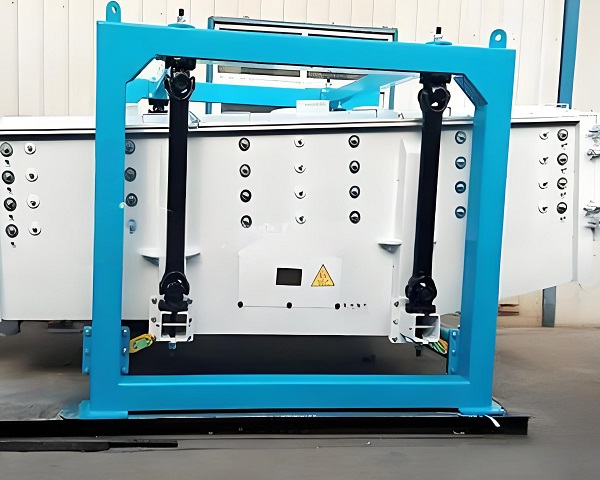

The bouncing screen has achieved breakthroughs in technology such as intelligent control and structural innovation, which greatly improves efficiency and adaptability; its application covers multiple scenarios such as urban domestic waste and old waste, and its resource utilization effect is remarkable.

Magnetic separators play an important role in many industries, including mining, metallurgy, environmental protection, food processing, and building materials, due to their wide range of applications and excellent features.

With its wide range of applications and excellent characteristics, the gyratory screen plays an important role in many industries such as food processing, pharmaceuticals, chemicals, and mining.

The latest drum screen, thanks to technological breakthroughs such as multi-axis linkage, intelligent sensing, and self-cleaning, combines high precision, strong adaptability, energy saving, and environmental protection.