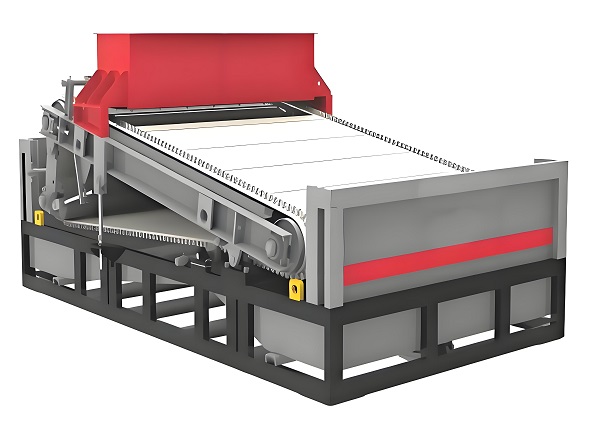

Magnetic separators are core equipment in the mining and solid waste treatment industries for separating ferromagnetic materials, and their stable operation directly affects production efficiency and product quality. However, long-term high-load operation can easily lead to problems such as magnetic field attenuation, component wear, and material blockage. Without proper scientific maintenance, the equipment's lifespan will be significantly shortened, increasing operating costs. This article provides a systematic and operable maintenance plan from four aspects: daily maintenance, periodic maintenance, fault prevention, and handling of special operating conditions, helping enterprises ensure efficient equipment operation and reduce production risks.

Daily Maintenance: Essential Basic Maintenance Performed Every Day

Equipment Appearance and Operating Status Inspection: Before starting the machine each day, clean the surface and surrounding area of the magnetic separator to remove scattered materials and dust. Check for deformation of the machine body and loose bolts, paying particular attention to whether there is material accumulation or blockage at the feed inlet and outlet. During operation, assess the equipment's condition by listening, looking, and touching: listen for abnormal noises from the transmission components, check whether the material adsorption in the magnetic field area is uniform, and feel the temperature of the motor and bearing housings (normally ≤60℃; if it exceeds 70℃, stop the machine immediately). After shutdown, promptly clean any residual ferromagnetic impurities from the drum surface to prevent long-term adsorption from affecting the magnetic field strength.

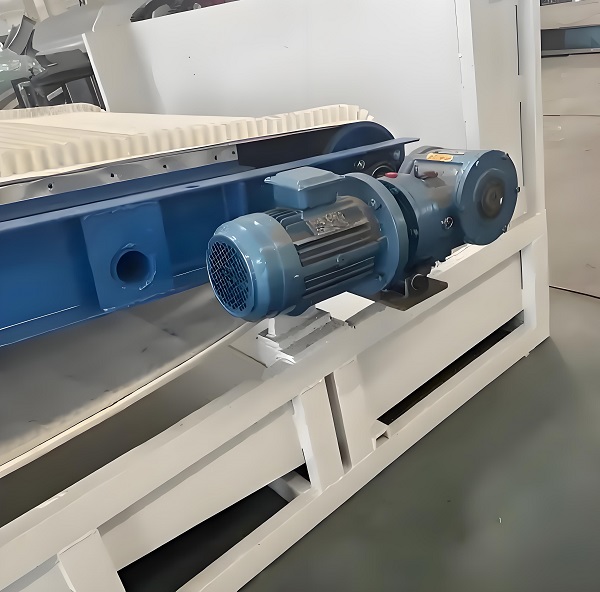

Daily Lubrication System Maintenance: Check the lubricating oil level in all transmission parts daily. For example, the oil level in the reducer box should be maintained at 1/2-2/3 of the oil gauge. If insufficient, replenish with the same type of lubricating oil (46# anti-wear hydraulic oil is recommended). Add lithium-based grease to the bearing housing 1-2 times daily, adding only enough to overflow from the gaps each time to avoid overheating the bearings. Also, observe the lubricating oil for deterioration. If it turns black or emulsifies, replace it immediately and clean the oil chamber.

Magnetic Field and Drum Inspection: Use a gaussmeter to test the magnetic field strength on the drum surface daily to ensure the adsorption force meets production requirements (generally, the surface magnetic field strength of a permanent magnet drum separator should be ≥1200GS). If a weakened magnetic field is observed in some areas, check whether it is due to wear on the drum surface or displacement of internal magnetic blocks. In addition, check the rubber lining on the roller surface for damage or detachment. If cracks or local wear exceeding 3mm are found, repair or replace it promptly to prevent material from directly abrading the roller body.

2. Regular Maintenance: Periodic Deep Maintenance

Weekly Maintenance Focus: Perform a comprehensive disassembly and inspection of the equipment weekly: Remove the bearing end cover and check for wear on the inner and outer rings of the bearings and the integrity of the balls. If rust or excessive clearance is found, replace immediately; clean the dust inside the magnetic system and check for loose or detached magnetic blocks. If necessary, re-fix them with epoxy resin; check the tension of the drive belt. Press the middle of the belt with your finger; the deflection should be between 10-15mm. If it is too loose or too tight, adjust it by adjusting the motor base bolts.

Monthly Maintenance Items

Perform a thorough monthly maintenance on the gearbox: drain the old oil and clean the oil chamber, replace with new lubricating oil, and check gear wear. If pitting, scuffing, or wear exceeding 15% of the original tooth thickness is observed, repair or replace the gears immediately. Calibrate the uniformity of the magnetic field distribution; use a magnetic field distribution meter to test the magnetic field on the roller surface. If significant unevenness is observed, adjust the internal magnetic block arrangement. Check the motor insulation performance; use a megohmmeter to measure the insulation resistance of the motor windings. At room temperature, it should be ≥0.5MΩ; if insufficient, dry the motor.

Quarterly and Annual Maintenance Plan

Perform a precision calibration on the equipment quarterly: adjust the gap between the roller and scraper (generally maintained at 1-3mm) to ensure thorough scraping of ferromagnetic materials. Check for cracks at the frame welds; if stress corrosion is present, repair welding and apply anti-rust paint. Clean dust from inside the electrical control cabinet, check for burnt contactors and relay contacts, and replace aging wires and cables.

Annual maintenance requires a comprehensive disassembly and overhaul: replace all bearings, seals, and other easily worn parts; perform a dynamic balancing test on the drums; if the deviation exceeds 5g·cm, correction is necessary; check the magnetic attenuation of the magnetic blocks; if the overall magnetic field strength decreases by more than 20%, the magnetic system must be replaced; perform overall rust prevention treatment on the equipment, and apply anti-corrosion coating to the outer surfaces of the frame and drums to extend the equipment's service life.

3. Fault Prevention: Avoiding Common Problems in Advance

Prevention of Material Blockage and Jamming: Install a grid at the feed inlet to prevent large pieces of material from entering the equipment and causing jamming; regularly clean the accumulated material inside the equipment, especially at the bottom of the magnetic separator and under the scraper, to avoid material buildup leading to increased transmission resistance; adjust the feed speed to ensure that the material is evenly distributed on the drum surface and avoid localized overload. For minor blockages, the drums can be reversed for cleaning; in severe cases, the machine must be stopped and disassembled for cleaning. Forced restarting is prohibited.

Magnetic Field Attenuation Prevention: Avoid direct collisions between the roller surface and sharp materials to prevent damage to the magnetic blocks; prolonged operation in high-temperature environments is strictly prohibited (applicable temperature ≤80℃). If handling high-temperature materials, a cooling device must be installed; regularly perform moisture-proof treatment on the magnetic system, especially in humid environments, placing desiccant inside the equipment to prevent the magnetic blocks from rusting and causing magnetic attenuation.

Electrical Fault Prevention: The electrical control cabinet must be equipped with a cooling fan to prevent component aging due to high temperatures; regularly check the reliability of the grounding line to prevent leakage accidents; install an overload protection device at the motor power supply terminal, automatically cutting off power when the current exceeds 1.2 times the rated value to protect the motor from overload damage. In addition, establish an equipment operation log to record daily operating parameters, and predict faults in advance through data changes; for example, an abnormally high current may indicate bearing wear or material blockage.

4. Special Operating Condition Maintenance: Targeted Solutions for Complex Scenarios

High Humidity Material Handling Maintenance: When handling materials with a moisture content exceeding 30%, check the drum surface daily for condensation. If material adhesion occurs, apply an anti-stick coating to the drum surface. Strengthen bearing housing seals by replacing them with double-lip seals to prevent moisture infiltration and bearing corrosion. Regularly clean condensate from electrical components to prevent short circuits.

High Dust Environment Maintenance: Install dust covers at the equipment's inlet and outlet, using them in conjunction with a bag filter to reduce dust entering the equipment. Shorten lubrication cycles, adding grease to bearings daily to prevent dust from entering and causing wear. Disassemble the magnetic separator casing weekly to clean dust from the magnetic system surface to prevent dust from affecting magnetic field strength.

Magnetic separator maintenance requires a comprehensive system that combines daily basic inspections with periodic in-depth maintenance, from daily visual, lubrication, and magnetic field checks to targeted weekly, monthly, and annual maintenance. Meanwhile, proactively preventing material blockages, magnetic field attenuation, and electrical faults, and implementing adaptive measures for special operating conditions such as high humidity and high dust levels, can effectively reduce equipment failures. Scientifically implementing these maintenance points can significantly extend the lifespan of the magnetic separator, ensuring its continuous and stable separation function and providing strong support for cost reduction and efficiency improvement for enterprises.