In modern industrial production systems, material screening is a crucial link between raw material processing and finished product processing, directly impacting production efficiency and product quality. Traditional screening equipment often faces problems such as low efficiency, insufficient precision, and weak adaptability, making it difficult to meet diverse industrial needs. The gyratory screen, as a new type of screening equipment, uses a core principle mimicking manual shaking, integrating structural optimization and performance innovation. It has demonstrated significant advantages in the food, pharmaceutical, chemical, and mining industries, becoming an important force driving the upgrading of industrial screening technology. A thorough understanding of its applications and characteristics is crucial for enterprises to optimize production processes and enhance competitiveness.

In the material handling stage of industrial production, screening equipment plays a vital role, and the gyratory screen, as an important member of this chain, is widely used in multiple industries due to its unique working method and excellent performance. The following will detail the applications and characteristics of the gyratory screen.

Applications of the Gyratory Screen

Based on the working principle mimicking manual shaking, the gyratory screen achieves efficient screening of different materials through a reasonable combination of amplitude, vibration frequency, and screen surface angle. Its applications widely cover multiple industrial fields.

1. Food Processing Industry

In food processing, the purity and particle size of raw materials and finished products directly affect product quality. A vibrating screen can finely sieve various food raw materials. For example, in flour processing, it effectively removes impurities and bran, ensuring the flour's fineness and purity, meeting the demands of high-quality flour production. For granular foods such as sugar and salt, a vibrating screen can separate products of different particle sizes to suit various food processing scenarios. For instance, fine-grained sugar is needed for pastry making, while medium-grained salt may be more suitable for pickled foods. Furthermore, in nut processing, a vibrating screen can separate broken shells and debris, and also grade nuts by size, facilitating subsequent packaging and sales, and enhancing the product's commercial value.

2. Pharmaceutical Industry

The pharmaceutical industry has extremely strict standards for the purity and particle size of materials. The vibrating screen, with its high-precision sieving capabilities, plays a crucial role in this industry. In the processing of traditional Chinese medicine (TCM) materials, gyratory screens can sieve TCM powders, removing coarse fibers and impurities to ensure the purity of the powder meets pharmaceutical standards, thus guaranteeing the quality of TCM preparations. For raw materials in Western medicine production, such as antibiotic powders and vitamin granules, gyratory screens can precisely control particle size, ensuring the uniformity of the raw materials and thereby guaranteeing the efficacy and stability of the drugs. Furthermore, the application of gyratory screens in the pharmaceutical industry complies with GMP (Good Manufacturing Practice) requirements; their excellent sealing performance effectively prevents cross-contamination of materials, meeting the stringent hygiene standards of pharmaceutical production.

3. Chemical Industry The chemical industry involves a wide variety of materials with diverse properties, such as powders, granules, and lumps. Some materials are corrosive, flammable, or explosive, placing high demands on screening equipment. Gyratory screens can adapt to the complex working conditions of the chemical industry, effectively screening chemical raw materials. For example, in the production of plastic granules, gyratory screens can screen plastic granules of different sizes, removing unqualified impurity particles, ensuring the quality of the plastic granules, and providing high-quality raw materials for subsequent plastic molding processes. In fertilizer production, gyratory screens can separate lumpy materials and impurities, resulting in uniform fertilizer particles and improved application effectiveness. Furthermore, in the production of chemical products such as paints and pigments, gyratory screens remove coarse particles and impurities, ensuring product fineness and uniformity, thus improving product quality and performance.

4. Mining Industry In mineral mining and processing, ore needs to be crushed and screened to extract valuable minerals. Gyratory screens can classify and separate crushed ore into different particle sizes, providing suitable material for subsequent beneficiation processes. For example, in coal mining, gyratory screens can screen coal of different particle sizes, such as lump coal and fine coal, meeting the needs of different users, while removing impurities such as gangue, improving coal quality. In metal ore processing, gyratory screens can screen crushed metal ore, separating ore particles that meet beneficiation requirements, improving beneficiation efficiency and recovery rate, and reducing beneficiation costs.

Features of the Gyratory Screen

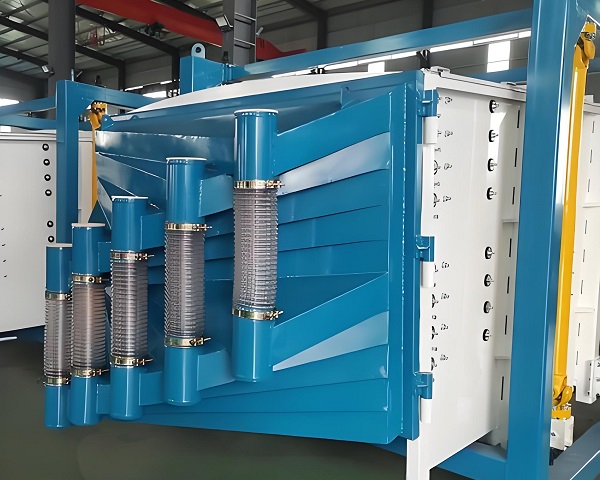

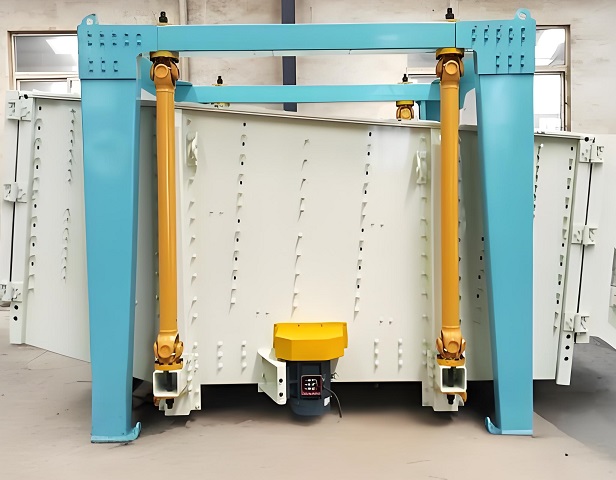

1. Rational Structural Design

The gyratory screen adopts a unique structural design, with a compact overall structure, occupying little space, and facilitating installation and layout in different production sites. Its screen box is made of high-strength materials, possessing good rigidity and stability, capable of withstanding large material loads and vibration impacts, extending the equipment's service life. Simultaneously, screen replacement is convenient and quick; screen disassembly and installation can be completed through simple operations, reducing equipment downtime and improving production efficiency. Furthermore, the equipment's transmission parts use high-quality bearings and seals, ensuring smooth and reliable operation, low failure rate, and convenient maintenance.

2. High Screening Efficiency

The gyratory screen, through a motion trajectory mimicking manual shaking, allows materials to move fully on the screen surface, increasing the contact opportunities between materials and the screen, thereby improving screening efficiency. Compared to traditional vibrating screens, the vibration frequency and amplitude of the gyratory screen can be flexibly adjusted according to the characteristics of the material and screening requirements, better adapting to the screening needs of different materials. For materials that are difficult to screen, such as sticky materials and fine particles, the gyratory screen, through reasonable parameter settings, can effectively reduce material blockage on the screen surface, ensuring smooth screening and further improving screening efficiency. Generally, the screening efficiency of the gyratory screen can reach over 95%, far exceeding that of traditional screening equipment.

3. High Screening Accuracy Due to the stable motion trajectory of the gyratory screen, the material is evenly distributed on the screen surface, effectively avoiding local accumulation and over-screening, thus ensuring screening accuracy. Its screen mesh is made with a high-precision weaving process, with accurate screen hole sizes and small errors, enabling precise separation of materials of different particle sizes. At the same time, the vibration amplitude of the screen box is small during operation, reducing particle size damage caused by violent vibration and ensuring the uniformity of particle size after screening. For industries with high screening accuracy requirements, such as pharmaceuticals and electronic materials, the gyratory screen can meet their stringent accuracy requirements, providing reliable assurance for product quality.

4. Low Operating Noise The gyratory screen is designed with noise control in mind, employing various noise reduction measures. Its transmission system utilizes high-quality gears and bearings, coupled with a well-designed lubrication system, reducing noise generated by mechanical friction. Simultaneously, the screen box and frame employ an elastic connection, effectively absorbing vibration energy and reducing vibration noise during operation. Furthermore, the equipment's outer casing is made of sound-insulating materials, further reducing noise transmission. Under normal circumstances, the operating noise of the gyratory screen can be controlled below 75 decibels, far lower than the noise level of traditional vibrating screens, providing operators with a good working environment and meeting environmental protection and occupational health requirements.

5. Low Energy Consumption The gyratory screen employs an advanced drive device and optimized transmission structure, effectively reducing energy consumption while ensuring normal operation and screening efficiency. Compared to traditional vibrating screens, the gyratory screen has a smaller motor power, resulting in lower energy consumption during operation. At the same time, the equipment's motion trajectory is optimized, minimizing material resistance on the screen surface and reducing energy waste. According to actual application data, under the same processing capacity, the energy consumption of the gyratory screen is 20%-30% lower than that of the traditional vibrating screen, saving enterprises significant energy costs and improving their economic efficiency.

6. High Adaptability

The gyratory screen can adapt to the screening needs of different types and properties of materials, effectively screening granular, powdery, sticky, and moist materials. By adjusting parameters such as amplitude, vibration frequency, screen angle, and screen aperture, precise screening of different materials can be achieved. Furthermore, the processing capacity of the gyratory screen can be adjusted according to production needs, ranging from several tons to tens of tons, meeting the production requirements of enterprises of different sizes. In addition, the gyratory screen can operate in various working environments, such as high temperature, low temperature, humidity, and dusty environments, demonstrating strong environmental adaptability.

Due to its wide range of applications and excellent characteristics, the gyratory screen plays an important role in many industries, including food processing, pharmaceuticals, chemicals, and mining. As industrial production demands increasingly higher standards for material screening, gyratory screen technology will continue to innovate and develop, providing stronger support for efficient and high-quality industrial production. In practical applications, enterprises should rationally select and use gyratory screens based on their material characteristics, production needs, and working environment to fully leverage their advantages, improve production efficiency and product quality, and reduce production costs.

The gyratory screen, with its unique principle mimicking manual shaking, achieves high-efficiency applications across multiple industries: it meets the stringent purity and precision requirements of the food and pharmaceutical industries, and adapts to the complex materials and working conditions of the chemical and mining industries. Its rational structure, high-efficiency and precise screening, low noise, energy saving, and strong adaptability address many pain points of traditional screening equipment, providing strong support for cost reduction and efficiency improvement for enterprises. With the development of intelligent and green industries, the gyratory screen needs further technological upgrades, such as incorporating intelligent control and optimizing environmentally friendly design, to play a more significant role in more niche areas in the future, continuously empowering high-quality development of industrial production.