In the industrial production chain of "material conveying-processing," the vibrating feeder, as a key piece of equipment connecting raw material storage and subsequent processing, uses a motor-driven eccentric block to generate directional vibration, uniformly and stably conveying materials from storage devices such as silos and hoppers to downstream equipment such as crushers, screening machines, and conveyors, achieving the core goal of "on-demand feeding and precise quantity control." Compared to traditional screw feeders and belt feeders, vibrating feeders offer advantages such as high conveying efficiency, precise quantity control, and adaptability to harsh working conditions when handling materials in various forms, including lumps, granules, and powders. They are widely used in mining, construction, chemical, and metallurgical industries. The following section will comprehensively analyze the practical value and technical advantages of vibrating feeders from two aspects: their core function and typical characteristics.

I. Core Functions of Vibrating Feeders: Connecting Production Processes and Ensuring Efficient Operation

The function of vibrating feeders revolves around three core objectives: "uniform feeding, stable conveying, and auxiliary pre-processing." In different industry scenarios, by adjusting vibration parameters (amplitude, frequency) and structural design, they meet the personalized needs of downstream equipment, ensuring the smooth operation of the production process.

1. Mining Industry: The "Front-End Conveying Hub" of Ore Pre-processing

The mining industry is a core application area for vibrating feeders, primarily used for "feeding before coarse crushing" and "uniform feeding before screening" after ore mining. This prevents downstream crushing and screening equipment from overloading or becoming inefficient due to uneven feeding. In metal ore (such as iron and copper) mining scenarios, after the raw ore is mined from underground or open-pit mines, it is temporarily stored in large silos. If directly fed into a jaw crusher, material accumulation can easily cause the crusher to jam and the motor to overload. At this stage, a vibrating feeder (mostly a heavy-duty plate vibrating feeder) is installed between the hopper outlet and the crusher. Through an amplitude of 3-5mm and a vibration frequency of 900-1200 times/minute, it evenly conveys the raw ore to the crusher inlet. The feed rate can be steplessly adjusted from 50-500 tons/hour by adjusting the vibration frequency. Data from an iron ore project shows that after equipping the machine with a vibrating feeder, the crusher's jamming failure rate decreased from 6 times per month to 1 time, crushing efficiency increased by 25%, and motor lifespan was extended by 30%.

In non-metallic mineral processing (such as limestone and granite), the vibrating feeder also plays a role in "screening assistance and material homogenization." After blasting, limestone has a large particle size difference; if the particle size is unevenly distributed before entering the screening machine, it will lead to localized overload of the screen and a decrease in screening accuracy. The vibrating feeder, through its "wide-range vibrating conveyor" design (conveyor belt width 1.2-2.5 meters), evenly spreads material on the screen surface of the screening machine, increasing material distribution uniformity from 60% to 90%, increasing screening machine throughput by 15%, reducing screen wear rate by 40%, and extending the replacement cycle from 1 month to 2 months.

2. Construction Industry: "Key to Pre-Sorting Quantity Control" in Construction Waste Treatment

With the advancement of the "construction waste resource utilization" policy, the vibrating feeder has become the "front-end regulator" of the construction waste treatment production line. It is mainly used for "uniform feeding" and "impurity pre-separation" before construction waste crushing, laying the foundation for subsequent recycled aggregate production. Construction waste (such as discarded concrete blocks, bricks, steel bars, and wood) is temporarily stored in a silo and then conveyed to an impact crusher via a vibrating feeder. The equipment employs an adjustable amplitude design (2-4mm). For large concrete blocks (300-500mm in diameter), the increased amplitude ensures smooth material transport. For mixed lightweight impurities (such as plastic film and wood chips), the low inertia of these impurities during vibration allows them to easily separate from the material surface and be collected by side scrapers, achieving preliminary impurity removal.

Data from a construction waste recycling project shows that the application of vibrating feeders controlled the feed rate fluctuation of the crusher to within ±5% (compared to ±20% for traditional manual feeding), improving the particle size uniformity of the recycled aggregate by 30%. Simultaneously, through vibration-assisted impurity removal, the removal rate of lightweight impurities reached 65%, the processing load of subsequent magnetic separation equipment decreased by 20%, the steel rebar recovery rate increased by 10%, and the purity of recycled aggregate increased from 75% to 88%, meeting the requirements of the "Technical Specification for Application of Recycled Aggregate from Construction Waste".

3. Chemical Industry: "Precision Quantity Control Expert" for Powder Conveying

In the chemical industry, vibrating feeders are mainly used for the "precise feeding of powdery and granular chemical raw materials," avoiding chemical reaction imbalances caused by excessive or insufficient raw material feeding, and ensuring stable product quality. In fertilizer production, granular raw materials such as monoammonium phosphate and potassium chloride need to be mixed in specific proportions. If manual feeding is used, errors in the mixing ratio can easily lead to substandard fertilizer nutrient content. At this stage, a vibrating feeder (mostly a closed-type tubular vibrating feeder) is installed between the raw material silo and the mixer. Through a combination of a variable frequency motor and a weighing sensor, precise quantity control is achieved: the weighing sensor monitors the conveying volume in real time and feeds back to the PLC control system, adjusting the vibration frequency (500-800 times/minute) to ensure the feeding accuracy of a single raw material is controlled within ±1%. Data from a fertilizer plant shows that after applying a vibrating feeder, the nutrient content qualification rate of fertilizer products increased from 85% to 99%, raw material waste rate decreased by 8%, and annual raw material cost savings exceeded 1.2 million yuan.

In paint production, vibrating feeders are used for the closed conveying of pigments and fillers, avoiding dust pollution. The equipment adopts a fully sealed structure and, in conjunction with a negative pressure dust removal device, controls the dust concentration during powder conveying to below 5mg/m³, meeting national air pollutant emission standards. Simultaneously, by adjusting vibration parameters, the feed rate can be adjusted from 0.5 to 50 tons/hour, adapting to the production needs of different batches of coatings. Feeding stability is improved by 40% compared to screw feeders, avoiding color differences in coatings caused by uneven pigment delivery.

4. Metallurgical Industry: A "Stable Conveying Bridge" for High-Temperature Materials

In the metallurgical industry, vibrating feeders are used for "conveying and feeding high-temperature ores and slags," withstanding high-temperature environments to ensure continuous operation of the smelting process. In steel smelting scenarios, roasted iron ore (temperature 300-500℃) needs to be conveyed to a ball mill for grinding. If a conventional belt feeder is used, high temperatures will cause the belt to age and crack, shortening its service life to one month. The "high-temperature resistant plate vibrating feeder" uses heat-resistant steel (such as 310S stainless steel) for its feed trough and is equipped with high-temperature resistant sealed bearings. It can operate continuously in environments below 600℃, uniformly conveying high-temperature iron ore to the ball mill with a conveying capacity of 100-300 tons/hour. Data from a steel plant shows that the equipment has a service life of over 3 years, 36 times longer than ordinary belt feeders, and reduces annual replacement costs by 97%. Simultaneously, it improves feeding uniformity by 25%, ball mill grinding efficiency by 18%, and reduces steel ball wear by 15%.

In non-ferrous metal (such as copper and aluminum) smelting, vibrating feeders are used for "auxiliary material feeding before refining," such as uniformly adding desulfurizing agents and deoxidizers to the refining furnace. By precisely controlling the feed rate (error ≤ 0.5%), the auxiliary materials and molten metal react fully, increasing the desulfurization rate from 80% to 95%, improving the metal purity compliance rate by 20%, and reducing metal loss due to excessive auxiliary materials.

II. Typical Features of Vibrating Feeders: Technical Advantages Adaptable to Multiple Scenarios

The core reason why vibrating feeders are widely used in many industries lies in their unique structural design and performance advantages. They can solve the pain points of traditional feeding equipment when handling specific materials and meet the personalized needs of different scenarios.

1. Uniform and Precise Feeding with a Wide Control Range

By adjusting the amplitude (1-10mm) and frequency (500-1500 times/minute) of the vibrating motor, the vibrating feeder can achieve stepless adjustment of the feed rate from 0.1-1000 tons/hour, with a feeding uniformity error ≤ 5%, far superior to traditional screw feeders (error 10%-15%). Its core principle is: the directional vibration generated by the rotation of the eccentric block causes the material to advance in a "jumping" motion along the inclined surface of the trough, resulting in a uniform material layer thickness and preventing localized accumulation or material breakage. Combined with a variable frequency motor and weighing sensors, the feed rate can be adjusted in real time according to the needs of downstream equipment. For example, in the coarse crushing stage of a mine, when the crusher load is too high, the PLC system automatically reduces the vibration frequency and feed rate to avoid equipment overload; when the crusher load is too low, the frequency is increased to increase the feed rate and improve production efficiency. Comparative data from a chemical company shows that the feeding accuracy of the vibrating feeder is 3 times higher than that of the screw feeder, and the product qualification rate is increased by 14%.

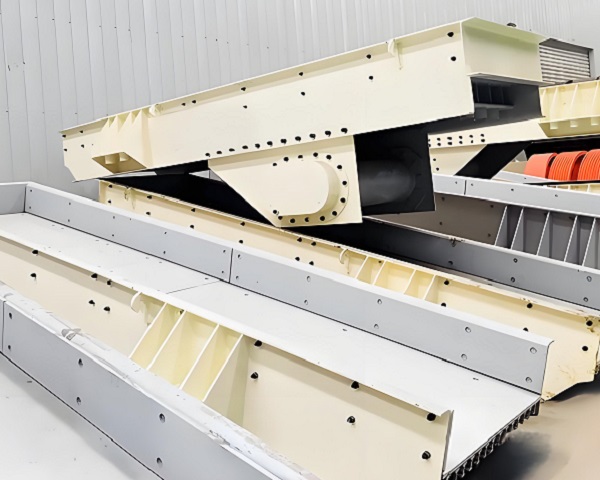

2. Simple and Compact Structure, Convenient Installation and Maintenance The core structure of the vibrating feeder consists of four parts: the hopper, the vibrating motor, the spring support, and the base. It eliminates complex transmission mechanisms (such as gears and chains), and the number of parts is only 1/3 that of a screw feeder. Its simple and compact structure requires little floor space (e.g., a 100-ton/hour processing capacity requires approximately 2-3 square meters). It can be directly installed between the hopper outlet and downstream equipment without complex foundation modifications. In terms of maintenance, daily checks only require inspecting the wear of the vibrating motor fixing bolts and spring support, and adding grease monthly. If parts need replacement, such as the hopper or vibrating motor, the modular design allows for quick disassembly, reducing replacement time from 4 hours for traditional equipment to 1 hour. Data from a mining project shows that the monthly maintenance time for the vibrating feeder is only 2 hours, a 75% reduction compared to the screw feeder (8 hours), resulting in a 60% reduction in maintenance costs.

3. Adaptable to various material forms and strong anti-clogging ability: The vibrating feeder features a flexible trough design that can be adjusted according to the material form (lumpy, granular, powdery): When processing lumpy materials (such as ore and construction waste), a "deep trough" trough (300-800mm deep) is used, coupled with a large amplitude (5-10mm) to prevent material jamming; when processing powdery materials (such as chemical raw materials and flour), a "shallow trough + sealed cover" design is used to prevent dust from flying, while a small amplitude (1-3mm) ensures uniform material flow; when processing sticky materials (such as wet clay and coal slime), the inner wall of the trough is coated with polytetrafluoroethylene (FPTFE) (friction coefficient 0.05-0.1), coupled with high-frequency vibration (1200-1500 times/minute) to prevent material adhesion and clogging. Data from a construction aggregate plant shows that when processing wet sand with a moisture content of 25%, the clogging failure rate of the vibrating feeder is only 3%, while the clogging failure rate of the screw feeder reaches 35%, effectively reducing downtime for cleaning.

4. Stable and reliable operation, low noise and low energy consumption. The vibrating motor of the vibrating feeder adopts an "eccentric block" design, ensuring uniform force distribution during operation without severe impact. The equipment's vibration frequency is stable, with amplitude fluctuations ≤±0.5mm, ensuring a consistently stable feed rate. Simultaneously, the spring supports use rubber or steel springs, which can absorb more than 80% of the vibration energy, reducing the impact of equipment vibration on the foundation and lowering the foundation bearing capacity requirement by 50%. Regarding noise control, the vibrating motor uses silent bearings, combined with "flexible contact" (no rigid collision) between the trough and the material, resulting in operating noise typically below 75 decibels, far lower than that of the screw feeder (90-100 decibels), meeting industrial noise emission standards (≤85 decibels) and improving the working environment for operators.

In terms of energy consumption, the motor power of a vibrating feeder is typically 0.75-15kW, and the energy consumption per ton of material processed is only 0.1-0.3kWh, which is more than 60% more energy-efficient than a screw feeder (0.3-0.8kWh/ton). Data from a mining project shows that a single vibrating feeder (5.5kW power) operating for 20 hours a day consumes an average of 110kWh of electricity per day, saving over 60,000 yuan in electricity costs annually compared to a screw feeder with the same processing capacity (15kW power, average daily electricity consumption of 300kWh).

5. Resistant to Harsh Working Conditions and Long Service Life: The core components of the vibrating feeder are made of wear-resistant, corrosion-resistant, and high-temperature-resistant materials, adaptable to harsh working conditions such as high dust levels in mines, high corrosion in chemicals, and high temperatures in metallurgy. The material of the feed trough is selected according to the application scenario: high-manganese steel (Mn13) is used in the mining industry, increasing wear resistance by 5 times and extending service life to 2-3 years; 316L stainless steel is used in the chemical industry, resistant to acid and alkali corrosion and capable of long-term operation in environments with a pH value of 2-12; and 310S heat-resistant steel is used in the metallurgical industry, withstanding temperatures above 600℃.

Furthermore, the equipment features a sophisticated sealing design: a "labyrinth seal" is used in mining scenarios to prevent dust from entering the bearings; a "fluororubber seal" is used in chemical scenarios to prevent leakage of corrosive media; and a "graphite seal" is used in metallurgical scenarios to withstand high temperatures. Data from a chemical company shows that a vibrating feeder made of 316L stainless steel, after 5 years of continuous operation in an environment containing hydrochloric acid mist, showed no significant corrosion. The failure rate of core components (motor, bearings) was less than 5%, and its service life was four times longer than that of ordinary carbon steel equipment.

6. It can be linked with other equipment to achieve automated production. The vibrating feeder can be linked with a PLC control system, sensors (weighing sensors, level sensors, temperature sensors), and downstream equipment (crushers, screening machines) to build an automated production system. For example, in a mining production line, the silo level sensor monitors the raw material storage level. When the level falls below a threshold, the vibrating feeder automatically starts to replenish the material. The weighing sensor monitors the feed rate in real time and feeds back to the PLC system, which automatically adjusts the vibration frequency to ensure a stable feed rate. When the crusher malfunctions, the PLC system immediately stops the vibrating feeder to prevent material accumulation. Data from an intelligent mining project shows that after linking with the automation system, the manual intervention rate of the production line decreased from 30% to 5%, production efficiency increased by 20%, and product qualification rate increased by 15%. Vibrating feeders, with their core functions of "uniform feeding, stable conveying, and adaptability to harsh working conditions," are indispensable in the production processes of many industries. Their precise feeding, simple structure, low energy consumption, and long service life address many pain points of traditional feeding equipment, providing strong support for the efficient, stable, and automated operation of industrial production. With the upgrading of industrial intelligence, vibrating feeders will further develop towards "intelligent control, multi-equipment collaboration, and green energy saving," continuously expanding their application boundaries and contributing greater value to cost reduction and efficiency improvement across various industries.