According to the World Bank's "Global Waste Management Report 2024," global municipal solid waste generation has exceeded 2.3 billion tons annually and is growing at an average annual rate of 7%. The growth rate in low- and middle-income countries is reaching 8%-10%. While the growth rate in high-income countries is slower (approximately 2%-3%), the proportion of recyclables and complex materials in their waste has increased significantly. Driven by the United Nations Sustainable Development Goal 11 (Sustainable Cities and Communities) and the consensus on global carbon neutrality, waste screening, as a core component in achieving "reduction, harmlessness, and resource utilization," has become a key indicator of waste management performance across countries. Fine shredders, as core pre-processing equipment before screening, have demonstrated differentiated and critical value in diverse waste management scenarios around the world. From "zero waste" systems in Europe to large-scale processing plants in Asia, from simple sorting facilities in Africa to intelligent recycling networks in North America, fine shredders are solving the challenges of mixed waste management in various regions through technological adaptation, becoming a key support for upgrading global waste screening systems.

Common Demand for Fine Shredders Despite Differences in Global Waste Composition: Addressing the Core Pain Point of Screening

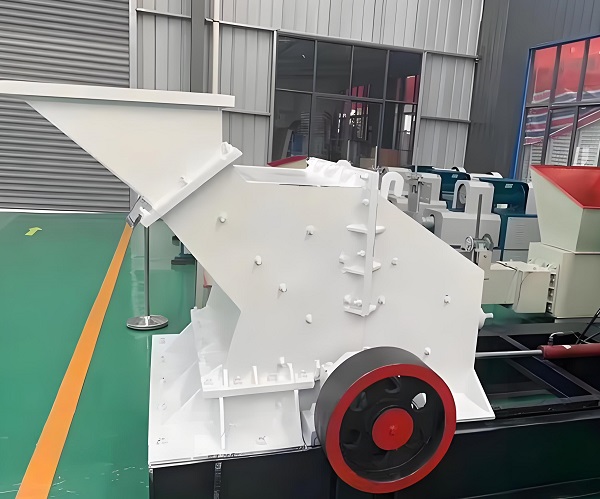

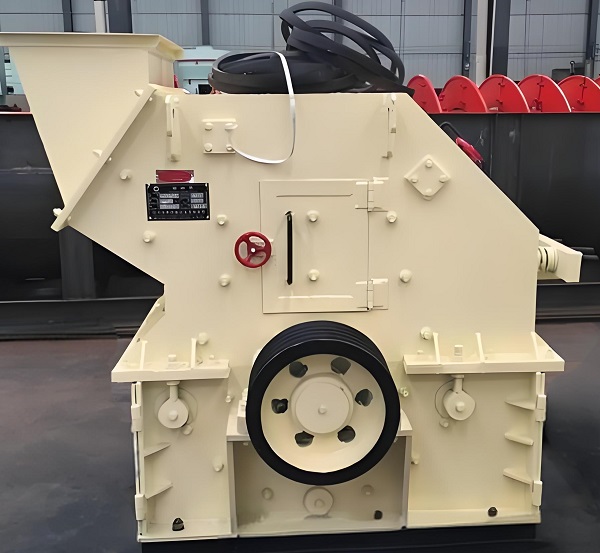

Globally, despite significant regional differences in waste composition—food waste accounts for approximately 30% and recyclable plastics for 15% of European waste, while food waste in Southeast Asian countries accounts for as much as 60%-70%; electronic waste and large furniture account for over 8% of North American waste; and inorganic materials (sand, gravel, bricks, and tiles) account for up to 25% of mixed waste in parts of Africa—the global waste management industry faces a common pain point: irregular material shapes, large lumps, and tough materials that hinder screening. In Europe, statistics from the German Waste Sorting Plant Alliance show that screening systems without fine-crushing pre-treatment equipment experience over 1,000 hours of downtime annually due to blockages caused by large materials such as mattresses and used appliance casings. At one Dutch waste treatment plant, unshredded large plastic pallets got stuck in the drum screen, causing the equipment chain to break, resulting in three days of production downtime. In Southeast Asia, data from a waste transfer station in Bangkok, Thailand, shows that tough materials such as plastic bags and woven bags account for 12% of mixed waste. After being directly fed to the vibrating screen, manual cleaning of entanglements is required four to five times a day, with each cleaning taking over an hour. The screening efficiency is only 65% of the design value. In Nairobi, Kenya, Africa, simple waste sorting sites lack fine-crushing equipment, making it difficult to effectively separate large pieces of wood waste from ceramic fragments. This results in a metal recovery rate of less than 20%, far below the global average of 35%. To address this common global pain point, tertiary crushers, through their "physical reshaping" capabilities, have become a solution that transcends regional differences. In high-income countries, tertiary crushers are often integrated with intelligent sensing systems to achieve precise crushing of different materials. In low- and middle-income countries, low-cost, highly durable tertiary crushing equipment is key to improving basic screening capabilities. In the United Nations Environment Programme (UNEP) 2023 Waste Treatment Equipment Assistance Program, tertiary crushers account for 40%, far exceeding other pre-treatment equipment.

Regional Practice Differences: The Adaptability of Tertiary Crusher Applications in Global Screening Systems

1. Europe: Synergy between Fine Crushing and Screening under the "Zero Waste" Goal

Europe was the first region in the world to promote "zero waste" policies. The EU's "Circular Economy Action Plan" calls for a municipal waste recycling rate of at least 65% by 2030. This goal is driving the development of tertiary crushers towards "fine and low-energy" technology. A waste sorting plant in Munich, Germany, utilizes a combined "two-stage fine crushing + intelligent screening" system. The first-stage fine crusher uses toothed rollers with adjustable gaps to shred large furniture and used mattresses to pieces smaller than 300mm, while preventing material mixing caused by over-crushing. The second-stage fine crusher utilizes "low-temperature shearing" technology (controlling the crushing temperature below the plastic's softening point) to target tough plastics and paper, preventing plastic adhesion that could affect subsequent sorting.

Data from the plant shows that after two stages of fine crushing, the purity of food waste in the screening system has increased from 58% to 92%, and the recyclable plastic recovery rate has reached 85%, significantly exceeding the EU average of 60%. Furthermore, thanks to the use of variable-frequency motors and intelligent load regulation, the fine crusher's unit energy consumption is only 60% of that of traditional equipment, meeting the energy efficiency requirements of the EU Ecodesign Directive for waste treatment equipment. Similar applications are widely used in countries like Sweden and Finland. The Stockholm waste treatment plant in Sweden even achieves precise separation of PET and HDPE plastics by integrating a fine shredder with near-infrared sorting equipment, achieving recovery rates of 90% and 88%, respectively.

2. Asia: Efficient Crushing and Cost Optimization in Large-Scale Processing Scenarios

Asia is the world's largest waste-generating region. Countries like China, India, and Japan all face the challenges of large-scale waste management, complex waste composition, and cost sensitivity. In this scenario, fine shredders prioritize efficient crushing, volume reduction, and energy efficiency. A Chinese multinational environmental group built a comprehensive waste treatment plant in Ho Chi Minh City, Vietnam. To address the high proportion of food waste (65%) and the high concentration of bulk materials (such as palm trunks and used motorcycle parts) in local waste, the company adopted a heavy-duty double-toothed roller fine shredder to shred mixed waste to sizes below 200mm, achieving a crushing efficiency of 150 tons/hour, a 50% improvement over existing local equipment. Operational data from the plant shows that after fine crushing, the clogging rate of screening equipment has dropped from 35% to below 5%, and the average daily processing capacity has increased from 800 tons to 1,200 tons. Furthermore, due to a 40% reduction in waste volume, transportation costs have dropped from $12 per ton to $7 per ton, saving over $2 million in transportation costs annually. In Japan, due to limited land resources, fine crushers also serve the purpose of reducing volume and footprint. A Tokyo waste transfer station used fine crushers to reduce waste volume by 50%. Combined with compression technology, this increased the station's storage capacity by two times, effectively alleviating the pressure of waste accumulation.

3. North America: Integrated Crushing and Sorting in an Intelligent Recycling System

Waste treatment in North America places a greater emphasis on "deep resource recovery." Fine crushers are often integrated with intelligent sorting equipment (such as magnetic separators and eddy current separators) to achieve an integrated "crushing-screening-sorting" process. An electronic waste processing plant in California, USA, uses a "low-temperature fine crushing + airflow screening" process to address the tight integration of metal and plastic in used computers, mobile phones, and other devices. The fine crusher crushes the electronic waste at -50°C, increasing the plastic's brittleness and allowing for more thorough separation of metal and plastic. Airflow screening then separates materials of varying densities.

Data from the plant indicates that this process has increased copper recovery rates from 75% to 95% and aluminum recovery rates from 68% to 88%. Low-temperature crushing also prevents plastic combustion and reduces harmful gas emissions, meeting the environmental requirements of the US Resource Conservation and Recovery Act. A waste sorting plant in Vancouver, Canada, uses a linkage between the fine crusher and an AI-powered visual sorting system to adjust the crushing gap in real time. When the system detects a high proportion of recyclable glass, it increases the gap to prevent excessive glass breakage; when it detects a high proportion of tough plastic, it reduces the gap to ensure adequate tearing, resulting in a 30% increase in resource recovery efficiency.

4. Africa: Low-cost, durable crushing for basic sorting scenarios

Most African countries have rudimentary waste treatment facilities, and the demand for fine crushers focuses on low cost, high durability, and easy maintenance. The United Nations Environment Programme, in collaboration with Kenya, has built a community waste sorting center in Naivasha that uses a "single-tooth roller simple fine crusher." Powered by a diesel engine (to accommodate local power instability), the crushing teeth are made of high-manganese steel, boasting a service life of 5,000 hours, and the unit cost is only one-fifth of similar European equipment.

Since the center's operation, the crushing rate of large pieces of mixed waste has increased from 30% to 85%, the recovery rate of recyclable metals has increased from 15% to 40%, and the amount of community waste going to landfill has been reduced by 25%. It has also created 20 maintenance and sorting jobs, achieving both environmental and social benefits. Similar simple fine crushing equipment has been deployed in countries such as Ethiopia and Tanzania, becoming the "entry-level" equipment for basic waste sorting systems in Africa.

Global Policy and Technology Trends: The Upgrading Value of Fine Crushers in Screening Systems

Driven by global carbon neutrality and circular economy policies, the role of fine crushers is evolving from a single crushing tool to a core hub in screening systems, demonstrating three major global trends:

1. Greening: Low energy consumption and environmentally friendly design become mainstream

The EU Industrial Emissions Directive requires a 20% reduction in energy consumption and a 15% reduction in carbon emissions for waste treatment equipment by 2027, driving the transition of fine crushers toward energy-saving motors and low-carbon processes. A German equipment manufacturer has developed a hydraulically driven fine crusher that uses an energy recovery system to convert hydraulic energy generated during the crushing process into electricity, reducing energy consumption by 25%. This has been used in over 200 waste treatment plants across Europe. A Japanese company has developed a biodegradable lubricant fine crusher to prevent waste contamination from traditional lubricant leaks, complying with the environmental requirements of Japan's Waste Disposal Act.

2. Intelligence: Deep Integration with Digital Technology

Leading global waste treatment equipment manufacturers have begun integrating the Internet of Things, AI, and big data into tertiary crusher design. A Swedish company has launched an "intelligent tertiary crushing system." This system uses pressure sensors and particle size monitoring cameras mounted on the toothed rollers to collect real-time data on material hardness and particle size. AI algorithms then automatically adjust the crushing speed and clearance. When processing hard materials (such as metal), the speed is reduced to protect the toothed rollers; when processing soft materials (such as plastic), the speed is increased to improve efficiency. This has reduced crushing energy consumption by 18% and reduced equipment failure rates by 40%. This system has been deployed in waste treatment plants in over 50 countries worldwide, setting a benchmark for intelligent upgrades.

3. Modularity: Adapting to Different Processing Scales

To meet the diverse processing scales across different regions of the world, tertiary crushers are moving towards modularization. A Swiss manufacturer has launched a "modular tertiary shredder" that can be flexibly combined with one to four crushing units, depending on the processing capacity (ranging from 10 tons/hour to 200 tons/hour). Each unit can be independently maintained, significantly reducing initial investment costs in low- and middle-income countries. This unit has been deployed in small and medium-sized waste treatment plants in countries such as Indonesia and the Philippines, helping to build screening and pre-treatment capabilities from scratch.

Global Value Consensus: Tertiary Shredders Promote the Transformation of Waste Screening Towards Sustainability

Global practice shows that while the functional requirements of tertiary shredders vary across regions, there is a consensus on their core value: using crushing to eliminate screening barriers, improve resource recovery efficiency, reduce overall processing costs, and ultimately promote the transition of waste management towards a "circular economy." A 2024 World Resources Institute (WRI) research report indicates that waste screening plants equipped with high-efficiency fine-crushing pre-treatment systems can increase global average resource recovery rates by 35%-45%, reduce landfill volume by 40%-50%, and reduce carbon emissions per unit of waste processed by 20%-30% compared to traditional systems. This data has been verified in Europe, Asia, North America, and other regions.

With the increasing global emphasis on "waste-to-resource" recycling, fine-crushers will further integrate with global screening technology trends. In Europe, they are being combined with "chemical recycling" technologies to achieve efficient crushing and cracking of plastics; in Asia, they are being adapted to "anaerobic fermentation" processes to improve the efficiency of food waste degradation; in North America, they are being integrated with "deep resource sorting" systems to achieve precise recovery of precious metals; and in Africa, they are being enhanced through "simplified technology transfer" to improve basic screening capabilities. It can be said that fine-crushers are no longer just "pre-treatment equipment" for waste screening; they are also key technological vehicles for achieving the global goal of "sustainable waste management," providing countries at different levels of development with a viable path to overcome waste disposal challenges.