In the process of upgrading industries such as solid waste resource utilization and fine mineral processing in mines, the drum screen, as a key grading equipment, directly affects the efficiency and benefits of downstream industries in terms of its technical level. From traditional simple screening equipment to efficient equipment that integrates intelligent control, the evolution of drum screens has always closely followed the policy orientation of environmental protection and intelligent manufacturing. Currently, the energy efficiency requirements under the "dual carbon" target and the screening needs of complex working conditions are driving its technological breakthroughs into an accelerated period. This article focuses on the current development status of drum screen technology, analyzes core innovation points, and predicts future trends, providing reference for industry development.

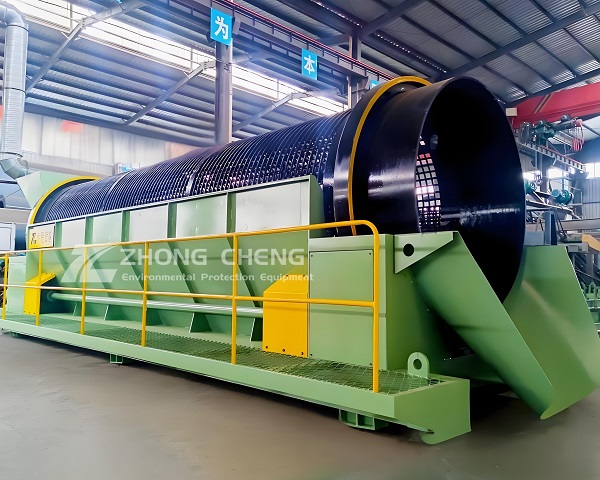

As an indispensable core screening equipment in various fields such as solid waste treatment, mining beneficiation, building materials production, grain processing, and environmental engineering, the drum screen plays an irreplaceable role in the classification and treatment of various complex materials due to its unique cylindrical rotating screening principle. The basic working mechanism is to drive the drum to rotate at low speed through a motor. After the material enters from one end of the drum, it slides along the drum wall under the combined action of gravity and rotational force. Materials smaller than the sieve hole are discharged from the corresponding sieve area, while materials larger than the sieve hole are discharged from the other end of the drum, thus completing the classification and screening of materials. With outstanding advantages such as stable structural operation, strong adaptability to materials with high moisture content and viscosity, and relatively easy maintenance and operation, the drum screen has continued to play a role in China's industrialization process and is constantly iterating and evolving in the wave of industrial upgrading and technological innovation. At present, the national "dual carbon" strategy has put forward energy efficiency improvement requirements for high energy consuming equipment, and the intelligent manufacturing policy has guided the digitization and intelligence of equipment, forming a dual driving force to promote the development of drum screen technology to break through the traditional framework, presenting a multi-dimensional collaborative progress trend in structure, materials, intelligent control, etc. At the same time, it also points out a clear and definite direction for its future technological evolution and industrial application.

From the perspective of current technological development, the drum screen has formed a three-dimensional technological pattern of "structural optimization, material innovation, and intelligent upgrading" that support each other and develop synergistically. Among them, innovative breakthroughs in structural design have become the primary lever for improving equipment operating efficiency. In traditional structures, the axial drum screen can ensure rotational stability due to the central axis passing through the cylinder. However, when dealing with materials such as metal wires, waste cables, branches, vines, and other long strip or fiber materials, it is prone to material entanglement around the central axis. This not only leads to a sudden drop in screening efficiency, but also may cause motor overload, bearing damage, and other faults, increasing equipment downtime and maintenance time and costs. In response to this pain point, shaftless drum screens have emerged and quickly become an emerging mainstream direction. This innovative structure completely abandons the traditional central support shaft and instead adopts a multi-point support formed by a set of supporting wheels and blocking wheels distributed along the circumference of the cylinder, which drives the drum to rotate through gears or friction transmission, fundamentally eliminating the risk of material entanglement. Taking the application case of a large recycled metal recycling enterprise as an example, the scrap steel processed by it is often mixed with impurities such as waste steel bars and cables. After replacing traditional shaft equipment with a shaftless drum screen, the winding problem was completely solved, and the average time between equipment failures was extended from 15 days to 25 days, reducing the failure rate by 40%. The daily processing capacity of a single production line also increased from 80 tons to 110 tons. At the same time, modular design has become a standard feature of current drum screen products. Designers have standardized and disassembled core components such as the screen mesh, cylinder section, and transmission device, and developed a quick disassembly and assembly connection structure - the screen mesh adopts a snap on or bolt quick fixing method, reducing the replacement time from the traditional 4 hours to less than 1 hour; The cylinder can be combined with module segments of different lengths and mesh sizes according to screening requirements, allowing the equipment to flexibly adapt to multi specification screening needs from 5mm fine particles to 150mm large blocks. Whether it is ore grading in mining or aggregate screening in construction waste treatment, it can quickly adapt to working conditions, greatly improving the adaptability and market competitiveness of the equipment.

Material upgrading, as a key path to improve the durability of drum screens and reduce operating costs, has made significant breakthroughs in material selection and process innovation in recent years, completely changing the previous "one size fits all" material usage mode and forming a "scenario based customization" material system that accurately matches working conditions. In terms of cylinder material, traditional ordinary carbon structural steel often shows significant wear and deformation after 3-6 months of use in heavy load conditions such as mining and construction waste due to low strength and poor wear resistance, and requires repair or replacement. Nowadays, mainstream enterprises commonly use Q345B low-alloy high-strength steel as the base material for cylinder bodies. This steel, by adding alloying elements such as manganese and silicon, has a yield strength increased to over 345MPa, which is about 50% higher than ordinary steel. At the same time, it has good welding performance and impact resistance, and is not easy to crack when subjected to large material impacts, extending its service life to 1-2 years. On the core screen components, scenario customization features are more prominent: in heavy working conditions such as mines and sand and gravel fields where materials have high hardness and severe wear, high manganese steel screens have 3-5 times higher wear resistance than ordinary steel due to their surface work hardening characteristics after impact. After being applied in a certain sand and gravel enterprise, the screen replacement cycle has been extended from 15 days to 60 days; In the presence of corrosive media in chemical and metallurgical industries, 304 or 316L stainless steel mesh, with its excellent acid and alkali resistance, effectively avoids the problem of decreased screening accuracy caused by corrosion perforation of the mesh, and its service life can reach 8-12 months; In the field of resource utilization of construction waste, polyurethane composite screen has become a new choice. It adopts polyurethane elastomer and steel skeleton composite molding, which not only reduces the weight by 40% compared to metal screen and is easy to install and replace, but also effectively reduces the phenomenon of material blocking the screen holes with elastic structure. The screening efficiency is increased by 15%, and the service life is three times that of traditional metal screen, greatly reducing the frequency of screen replacement and maintenance costs. It is worth noting that in the field of high-end wear-resistant materials, the domestic substitution process of China's leading enterprises is accelerating. Previously, some high-end screening screens used for precision screening relied on imports, which were expensive and had long delivery cycles. Now, domestic enterprises have achieved domestic production of high-end screening screens through independently developed surface hardening treatment processes and composite molding technologies. The product performance has reached the international level, but the price has been reduced by more than 30%. This not only breaks the dependence on imports, but also reduces the comprehensive maintenance cost of the entire drum screening equipment by more than 15%, providing strong support for cost reduction and efficiency improvement in the industry.

Against the backdrop of industrial intelligent transformation, intelligent upgrading has become the core engine for upgrading drum screen technology. The deep integration of digital technologies such as the Internet of Things, artificial intelligence, and big data with traditional equipment is driving the leapfrog development of drum screens from "single machine passive operation" to "intelligent active operation and maintenance". In the past, the monitoring of the operating status of drum screens mainly relied on manual inspections by operators, which not only had low efficiency but also made it difficult to detect potential faults inside the equipment in advance. Often, maintenance could only be carried out after the equipment was shut down, resulting in significant production losses. Nowadays, mainstream intelligent drum screen models are fully equipped with multi-dimensional sensor systems. Vibration sensors, temperature sensors, and speed sensors are installed in key parts such as motors, bearings, and drums. Some high-end models are also equipped with voiceprint sensors and material flow sensors, which can collect key data such as vibration frequency, bearing temperature, drum speed, operating noise, and material processing volume in real time during equipment operation. The data is wirelessly transmitted to the cloud monitoring platform through industrial Internet of Things (IoT) modules. On the backend of the platform, AI algorithm models continuously analyze and process real-time data - when the bearing temperature exceeds the preset threshold of 10 ℃, the system automatically issues a first level warning to remind operation and maintenance personnel to conduct inspections; When there is abnormal fluctuation in vibration frequency, the algorithm can accurately determine the type of fault based on historical fault data, such as bearing wear, poor gear meshing, etc., and push specific repair suggestions to achieve preventive maintenance of "early warning, early diagnosis, and early treatment". The intelligent drum screen products launched by industry leaders such as Sinoma Equipment and CITIC Heavy Industries have achieved excellent indicators of screening efficiency of over 90% and unit energy consumption of less than 0.8 kWh/t with this intelligent operation and maintenance system. This energy consumption level is about 25% lower than traditional equipment, approaching the international advanced level. According to industry statistics, the market penetration rate of intelligent drum screens in China has reached 12.5% in 2023, and in large-scale application scenarios such as large mines and environmental protection industrial parks, the penetration rate has exceeded 30%. At the same time, improving environmental compliance has become an important dimension of technological upgrading. In response to the problem of dust overflow during the operation of traditional drum screens, the company has developed a fully sealed cylinder structure, combined with negative pressure dust removal systems and spray dust reduction devices, to strictly control the dust emission concentration during equipment operation within 10mg/m ³, far below the requirement of 30mg/m ³ in the Comprehensive Emission Standards for Air Pollutants. This not only protects the occupational health of operators, but also meets the strict regulatory requirements of environmental protection departments in various regions.

Combining policy guidance with market demand, the future technological development of drum screens will focus on the three core directions of "high efficiency and energy conservation, intelligent deepening, and scene expansion", forming a more precise and efficient technological system. In the field of high efficiency and energy conservation, technological upgrades will start with the core power and transmission system, gradually replacing traditional high energy consuming components - permanent magnet synchronous motors will become the mainstream configuration. This type of motor has a power factor of over 0.95 and an efficiency improvement of 10% -15% compared to traditional asynchronous motors. Combined with variable frequency speed regulation technology, it can automatically adjust the speed according to changes in material processing volume, avoiding energy waste caused by "big horses pulling small cars". It is expected that through the optimization combination of motors and transmission systems, the unit energy consumption of drum screens will be further reduced by 20%. The deep application of digital twin technology will become another important support for energy-saving upgrading. Enterprises can build a virtual digital model of the drum screen to comprehensively map the structural parameters, operating data, material characteristics and other information of the equipment to the virtual system. Before the installation and commissioning of the equipment, it can simulate the operating status under different working conditions in the virtual environment, optimize core parameters such as drum speed and screen inclination angle, not only greatly shorten the on-site commissioning cycle (from the traditional 7 days to less than 2 days), but also detect energy waste caused by improper parameter matching in advance, and achieve energy efficiency optimization throughout the entire life cycle. The core breakthrough direction of intelligent deepening is the mature application of adaptive control technology. Although some intelligent devices can achieve data monitoring and fault warning, manual intervention is still needed to adjust parameters. In the future, by integrating AI visual recognition system and particle size sensor at the feed inlet, material images and particle size distribution data entering the equipment can be collected in real time. AI algorithms can quickly analyze the composition, humidity, particle size distribution and other characteristics of the material, automatically adjust the drum speed, screen inclination angle and even screen vibration frequency, and achieve precise screening of "material adaptation". For example, when an increase in large particles is detected in the material, the system can automatically increase the drum speed to accelerate the material conveying speed; When the humidity of the material increases and it is prone to sticking, the screen self-cleaning device can be activated and the speed can be appropriately reduced to ensure screening efficiency. This fully autonomous adaptive control will elevate the intelligence level of the equipment from "auxiliary decision-making" to "autonomous operation".

The development of scenario customization will move towards a more specialized and specialized direction, breaking the current limitation of "one machine, multiple scenarios" and forming specialized equipment for specific fields. In the field of resource utilization of construction waste, with the annual increase of more than 2 billion tons of construction waste in China, the demand for efficient processing equipment is becoming increasingly urgent. In the future, an integrated drum screen equipment with both screening and crushing functions will be developed. The front end of the equipment will integrate a jaw type crushing module to preliminarily crush large construction waste and directly enter the drum screen for classification, avoiding the transfer of materials between the crushing and screening equipment, reducing energy consumption and site occupation. It is expected to improve the comprehensive efficiency of the construction waste treatment line by 30%. In the field of new energy materials, with the rapid development of industries such as lithium batteries and photovoltaic modules, the screening accuracy requirements for ultrafine powders such as positive electrode materials and silicon materials continue to increase. Specialized ultrafine powder drum screens will become a research and development focus. By using high-precision woven mesh screens and low-frequency vibration assisted screening technology, precise classification of materials below 1 millimeter or even 50 microns can be achieved, with screening accuracy errors controlled within 2%, meeting the strict requirements of purity and particle size for new energy materials. In terms of international market expansion, technological upgrades will be closely integrated with market demand. In response to strict energy efficiency certifications in Europe, North America, and other regions (such as EU CE certification and US ENERGY STAR certification), enterprises will accelerate the optimization of product energy consumption indicators and upgrade safety standards. By adopting low-noise transmission components, environmentally friendly coating materials, etc., they will meet the entry requirements of the international market. At the same time, relying on the overseas investment brought by the "the Belt and Road" initiative

The dual drive of policy and market will continue to accelerate technological iteration. The clear goal of comprehensive utilization of solid waste in the "14th Five Year Plan" for the development of circular economy, as well as the rigid constraints of industrial energy efficiency improvement policies, will force enterprises to increase research and development investment. It is expected that by 2026, the penetration rate of intelligent drum screens will increase to 28%, and the industry market size will exceed 5.2 billion yuan. Enterprises with core technology and full industry chain service capabilities will occupy the competitive high ground, promoting the comprehensive transformation of the drum screen industry from "scale expansion" to "value enhancement".

The drum screen technology has moved from traditional structure to the stage of coordinated development of "structure material intelligence". The optimization of shaftless and modular structure has solved traditional pain points, and the upgrading of scene based materials has reduced operation and maintenance costs. The intelligent transformation has achieved efficient operation and maintenance. In the future, efficient energy conservation, intelligent deepening, and scenario segmentation will become the core directions, and the application of technologies such as permanent magnet synchronous motors and digital twins will further enhance energy efficiency and intelligence levels. Driven by policies and markets, the industry will accelerate its transformation towards high value, and enterprises with core technologies will lead the development, providing solid equipment support for industrial upgrading.