A thorough understanding of the advantages and characteristics of shaftless trommel screens is of great practical significance for the rational selection of screening equipment, improving production efficiency, reducing operating costs, and promoting quality improvement and efficiency enhancement in the material screening process.

Improving the screening efficiency of a trommel screen requires a coordinated effort across four dimensions: material pretreatment, equipment parameter adjustment, routine maintenance, and standardized operation, with precise control over the key points in each stage.

The installation and commissioning of the disc screen must strictly follow standardized procedures, precisely controlling key aspects such as foundation construction, component assembly, and parameter calibration, in order to avoid various installation and operational hazards.

The mud and stone separator, with its targeted structural design and unique screening mechanism, achieves efficient separation of soil and aggregates, balancing sorting accuracy and processing efficiency. It is widely used in the material pretreatment stages of various industries, providing a guarantee for subsequent processing and resource recovery, and is an important piece of equipment for pra...

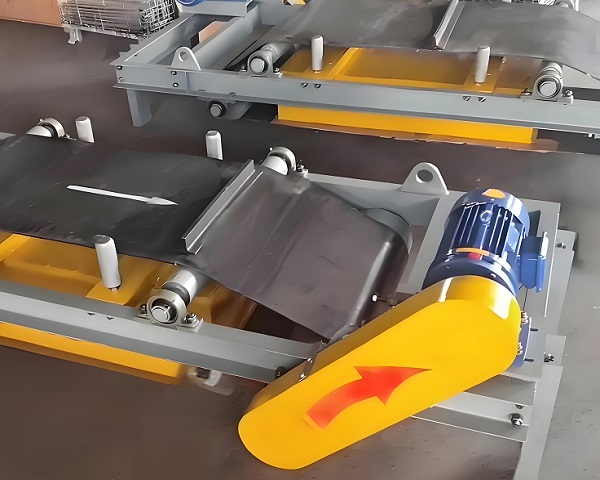

Magnetic separators, by precisely separating magnetic impurities, recovering usable magnetic resources, adapting to various sorting scenarios, and optimizing subsequent processing procedures, have become a core auxiliary equipment in waste sorting systems.

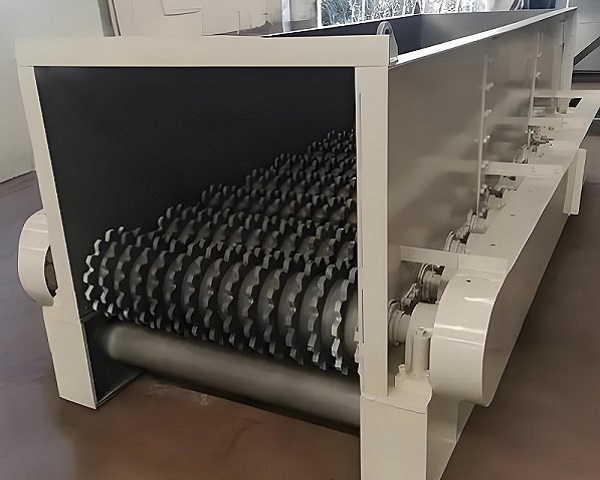

With its unique structure and operating characteristics, the finger screen solves the problems of material clogging and low efficiency encountered with traditional equipment, playing a crucial role in the screening of aged waste and laying a solid foundation for subsequent treatment.

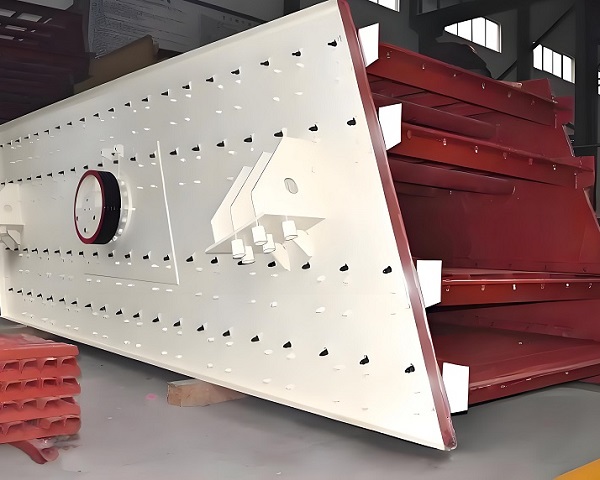

Vibrating screens, as core pre-processing equipment, play a crucial role in material classification and impurity separation, directly determining the efficiency and effectiveness of subsequent crushing, sorting, incineration, or landfill processes.

With its unique three-dimensional vibration principle, the swing screen breaks through the efficiency bottleneck of traditional screening equipment when processing viscous and damp materials, becoming a core piece of equipment in the chemical, food, and pharmaceutical industries.

This article, combining the structural principles of vertical waste balers and their practical application scenarios, comprehensively analyzes their core advantages and distinctive features. It also includes supplementary explanations based on practical details, providing comprehensive technical references for equipment selection, use, and maintenance.

Waste balers are core equipment in the environmental protection, waste treatment