As a highly efficient classification and screening equipment, the disc screen, with its unique disc structure, is suitable for material screening needs in various fields such as sand and gravel, mining, and waste disposal. The proper installation and commissioning of the disc screen directly determine the equipment's operational stability, screening accuracy, and service life. Compared to traditional screening equipment, the disc screen has a more complex structure, requiring higher standards for installation benchmarks, component connections, and parameter calibration. A scientifically completed installation and commissioning process can prevent malfunctions such as material blockage and abnormal vibration during operation, and maximize the equipment's efficiency, laying a solid foundation for large-scale and precise screening operations.

The installation of the disc screen must follow the principles of "precise positioning, standardized connection, and safety and stability," proceeding in four steps: preliminary preparation, foundation construction, main unit installation, and auxiliary component assembly. Each step requires strict attention to detail. In the preliminary preparation stage, it is necessary to verify the equipment model and installation site dimensions, clear the site of debris, level the ground, and plan the material conveying route. Simultaneously, check whether the equipment components are complete and in good condition, paying particular attention to checking for damage or deformation of core components such as discs, shaft assemblies, bearings, and frames. Prepare installation materials such as bolts and seals, as well as lifting and measuring tools in advance.

Foundation construction is the core prerequisite for installation. A concrete foundation must be poured according to the equipment manual, ensuring that the foundation strength meets the standards and the dimensions are accurate. Anchor bolt holes must be reserved during pouring, with a hole position deviation controlled within ±2mm to avoid affecting the subsequent main unit fixing; the top surface of the foundation needs to be leveled, with a flatness error not exceeding 0.5mm/m, to prevent resonance caused by uneven foundation during equipment operation. After concrete pouring, it needs to be cured for 7-10 days. Only when the strength reaches more than 80% of the design standard can the main unit installation begin.

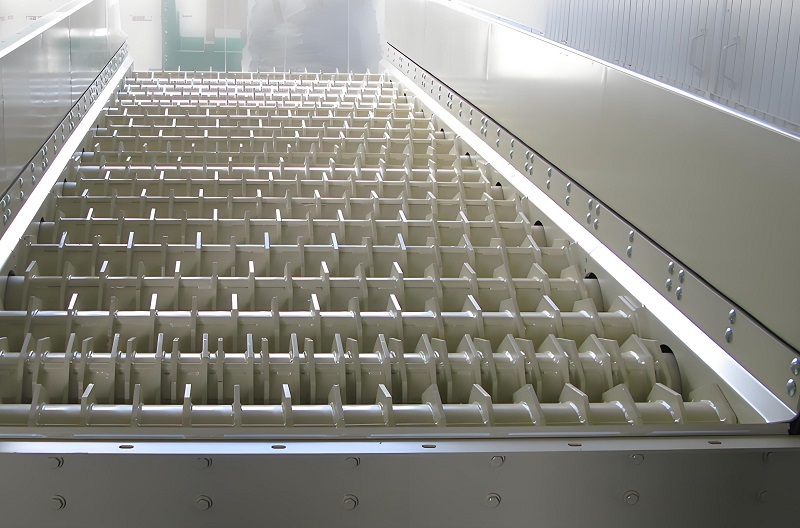

Main unit installation requires the use of professional lifting equipment. Slowly lift the disc screen main unit onto the foundation, adjust the horizontal and vertical alignment of the main unit, and use a level to check. The horizontal deviation should be controlled within 0.3mm/m, and the vertical deviation should not exceed 1mm/m. After calibration, tighten the anchor bolts. The bolts must be tightened to the specified torque, and anti-loosening washers should be added if necessary to prevent bolt loosening during equipment operation. Subsequently, the shaft assembly and discs are assembled. The discs must be installed with even spacing, with a deviation of no more than 1mm, ensuring smooth rotation without jamming or collision. Lubricating grease should be applied to the connection between the shaft assembly and bearings to improve operational smoothness.

The auxiliary components must be connected to the main machine's functions. The feed hopper, discharge port, conveyor belt, dust cover, and drive system are installed in sequence. The feed hopper must be precisely aligned with the main machine's feed port to prevent material spillage or uneven feeding; the conveyor belt tension should be adjusted appropriately, with a deviation of no more than 5mm; the connection between the drive system and the shaft assembly must be coaxial, with an error of no more than 0.2mm, to prevent abnormal noise or component wear during operation. Protective devices should also be installed to ensure operational safety during equipment operation.

Commissioning is crucial for ensuring the efficient operation of the disc screen and should be carried out comprehensively after installation and before formal production. It is divided into three stages: no-load commissioning, load commissioning, and precision calibration. Before no-load commissioning, check the connections of all components, confirming that bolts are tightened, lubrication is sufficient, and the electrical circuits are functioning correctly. Then, start the equipment and run it without load for 1-2 hours, observing the equipment's operating status. Pay particular attention to any abnormal noise, abnormal vibration, or rapid bearing temperature rise. If any faults occur, immediately stop the machine for inspection and correction.

Load commissioning involves gradually feeding material, starting at 50% of the rated load and gradually increasing to 100%, running for 3-4 hours. During commissioning, monitor the material screening effect, observe the flexibility of disc rotation and the stability of material transport, and adjust the feeding speed and equipment rotation speed to ensure that the material is evenly distributed on the discs, without clogging or leakage. Also, monitor the bearing temperature; during normal operation, the temperature should not exceed 75℃. If the temperature is too high, check the lubrication or component clearance and optimize the adjustments accordingly.

Precision calibration involves optimizing parameters for the screening effect. Based on the material particle size requirements, adjust the disc spacing, equipment amplitude, and vibration frequency to ensure that the screening accuracy meets the standards. If there is too much fine material in the screened material or too much coarse material in the undersize material, fine-tune the disc spacing or rotation speed until the classification requirements are met. After debugging is complete, all parameters must be recorded to create a debugging report, which will serve as a reference for subsequent equipment maintenance and parameter optimization.

The installation and debugging of the disc screen must strictly follow standard procedures, precisely controlling key aspects such as foundation construction, component assembly, and parameter calibration, to avoid various installation and operational hazards. Proper installation and debugging not only extend the equipment's service life but also improve screening efficiency and accuracy, adapting to the material processing needs of various fields. Regular maintenance and calibration should be performed based on the equipment's operating conditions to ensure long-term stable performance, supporting large-scale production and efficient resource utilization.