With the rapid development of mining, construction, river dredging, and waste disposal industries, the harmless treatment and resource recovery of soil and rock mixtures have become important issues. These materials have complex compositions and fluctuating moisture content, making them prone to clumping and sticking. Traditional screening equipment is easily clogged and has low separation efficiency, making it difficult to meet the needs of large-scale processing. Soil and rock separation machines, with their targeted structural design and unique screening mechanism, achieve efficient separation of soil and sand/gravel, balancing separation accuracy and processing efficiency. They are widely used in the pre-treatment of materials in various industries, providing a guarantee for subsequent processing and resource recovery, and are an important piece of equipment for practicing a circular economy.

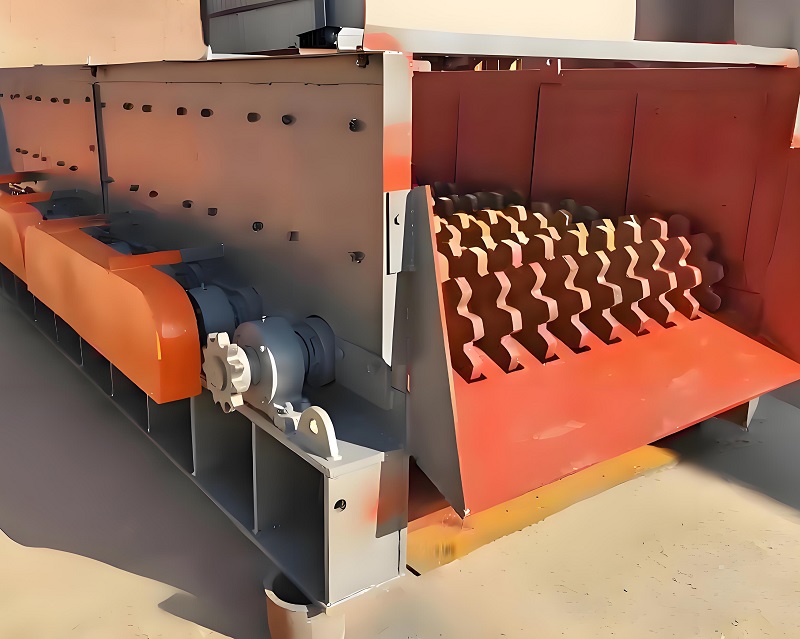

The screening principle of the soil and rock separation machine is based on graded screening + gravity sedimentation + self-cleaning, combining the physical characteristics of the materials to achieve precise separation, adapting to soil and rock mixtures with different moisture content and particle sizes. Its core structure consists of a screen box, eccentric vibration mechanism, screen bars, damping device, and drive system. The screen bars adopt a parallel rigid structure, and the spacing can be flexibly adjusted according to separation requirements, making them a key component for achieving graded separation. During operation, the drive system drives the eccentric mechanism to generate high-frequency, small-amplitude vibrations in the screen box. The amplitude and vibration frequency can be adjusted as needed to adapt to materials with different degrees of adhesion.

After the material is evenly fed into the screen surface through the inlet, it quickly spreads out under the action of vibration, forming a uniform material layer. Due to the significant differences in density and particle size between soil and sand/gravel, under the action of vibration inertia and gravity, small soil particles, dust, and mud will pass through the gaps between the screen bars and fall into the receiving device below, completing the initial separation; sand and gravel particles larger than the screen bar spacing will slide forward along the screen surface and finally be discharged from the outlet, achieving graded separation of soil and rock. For wet and sticky materials, the high-frequency vibration of the screen body generates centrifugal force, stripping the soil particles attached to the surface of the sand and gravel. At the same time, the rigid structure of the screen bars prevents wet mud from sticking and clogging, achieving self-cleaning of the screen surface and ensuring continuous screening operation. Compared to traditional screening equipment, the screening principle of the mud-rock separator offers significant advantages, effectively addressing the industry's pain point of wet material clogging and improving separation accuracy. Traditional perforated screens and woven screens are prone to clogging with mud when handling wet and sticky mud-rock materials, requiring frequent shutdowns for cleaning, which severely impacts processing efficiency. The mud-rock separator's open screen surface and high-frequency vibration design effectively overcome this problem. Even when processing wet and sticky materials with a moisture content exceeding 30%, it maintains stable screening performance, achieving a separation accuracy of over 90%, significantly superior to traditional equipment.

Based on its efficient screening principle, the mud-rock separator is widely used in the mining industry and is a core piece of equipment for ore pretreatment. Ores produced during mining often contain a large amount of mud and dust. If these are directly fed into the crushing and grinding stages, it will not only wear down equipment components but also reduce ore grade and affect subsequent beneficiation efficiency. The mud-rock separator can pre-screen the raw ore, separating out mud impurities and fine dust, improving ore purity, reducing the load on crushing equipment, extending equipment lifespan, and lowering operating and maintenance costs. It is suitable for large-scale processing needs in various mines, including coal mines, iron mines, and non-metallic mines.

In the construction and road construction fields, the mud-rock separator plays a crucial role in construction waste recycling and aggregate purification. Construction waste generated from building demolition and road reconstruction contains a large amount of mud, concrete blocks, and aggregates. After processing by the mud-rock separator, clean aggregate particles can be separated for the preparation of recycled aggregates, replacing virgin aggregates for road base paving, concrete mixing, etc., achieving the resource recovery of construction waste. Simultaneously, the separated mud components can be treated harmlessly and used for site backfilling, improving resource utilization.

The mud-rock separator is also applied in river dredging and environmental remediation scenarios. The sediment accumulated in riverbeds contains a large amount of silt, weeds, and household waste. After being screened by a mud-stone separator, clean sand and gravel can be separated for river restoration and dike reinforcement, while the silt can be dewatered and treated harmlessly for land improvement or environmentally friendly landfill, preventing environmental pollution caused by the indiscriminate dumping of silt. In the disposal of aged waste and construction waste, the mud-stone separator can also separate the soil from bricks, stones, and plastics, laying a solid foundation for subsequent precise sorting and resource recovery.

The mud-stone separator, relying on the core principle of combined grading and self-cleaning, solves the industry problem of sorting wet and sticky mud-stone materials. It boasts advantages such as high separation accuracy, strong adaptability, and convenient operation and maintenance, playing an important role in mining, construction, environmental protection, and other fields. With the advancement of resource utilization policies, its structure and performance will be continuously optimized to adapt to more complex material processing scenarios, providing strong support for promoting the development of a circular economy and improving the efficiency of environmental governance.