In the waste resource utilization and harmless treatment industry chain, vibrating screens, as core pre-treatment equipment, play a crucial role in material classification and impurity separation, directly determining the efficiency and effectiveness of subsequent crushing, sorting, incineration, or landfill processes. They utilize vibrations of different frequencies and amplitudes to achieve precise screening of various types of waste, adapting to a variety of solid waste treatment scenarios. With increasing environmental requirements and the development of more sophisticated waste treatment processes, the application range of vibrating screens continues to expand, and their structural and performance advantages are becoming increasingly prominent, making them important equipment for promoting quality improvement and efficiency in the waste treatment industry and practicing green development concepts.

A. Types of Waste Suitable for Processing by Vibrating Screens

The adaptability of vibrating screens primarily depends on the physical characteristics of the waste (particle size, moisture content, viscosity, hardness), and they are mainly used for the classification and sorting of various solid wastes. Based on the source of the waste, they can be divided into four main categories, covering mainstream treatment scenarios such as household, construction, and industrial waste, and also exhibiting a certain degree of adaptability to special wastes after pre-treatment.

1. Household Waste and Derived Waste

This is the most common application scenario for vibrating screens, mainly processing mixed municipal solid waste and derived waste after incineration and landfill. For mixed household waste that has not been pre-treated, vibrating screens can separate materials of different particle sizes, such as large plastic bottles, metal parts, and fabrics; medium-sized paper scraps, fruit peels, and kitchen waste; and fine dust and sand, laying the foundation for subsequent classified recycling (such as plastic and metal resource utilization) and harmless treatment (such as kitchen waste anaerobic fermentation and waste incineration).

For incinerator bottom ash and fly ash, vibrating screens can screen out large impurities from the bottom ash, classifying out aggregates that meet standards for resource utilization in road subgrades, brick making, etc.; for fly ash, after solidification treatment, vibrating screens can separate unqualified particles to ensure that subsequent disposal meets standards. It should be noted that when processing high-moisture kitchen waste, an anti-clogging structure is required to prevent material clumping and screen blockage.

2. Construction Waste and Renovation Waste

Construction waste has a complex composition but is relatively hard and less viscous, making it suitable for classification and processing by vibrating screens, and it is one of the core pieces of equipment for the resource recycling of construction waste. The treatable construction waste includes sand and gravel, concrete blocks, bricks, tile fragments, waste rebar, and wood waste. Using screens with different mesh sizes, aggregates of different particle sizes can be separated. Coarse aggregates can be used to prepare recycled concrete and road base materials, while fine aggregates can be used for mortar mixing and backfilling materials.

At the same time, vibrating screens can separate lightweight impurities (such as wood and plastic fragments) and metal impurities (such as waste rebar) from construction waste, improving the purity of recycled aggregates. For dust and fine particles in renovation waste, vibrating screens can achieve efficient screening, reducing dust pollution in subsequent processing and adapting to large-scale renovation waste treatment scenarios.

3. Industrial Solid Waste

Vibrating screens are suitable for the treatment of most industrial solid waste, especially waste materials with large particle size differences that require graded recycling. By industry, they can be divided into three categories: First, waste slag from the metallurgical and mining industries, such as blast furnace slag, steel slag, and mine slag. After grading by vibrating screens, useful minerals can be recovered, and qualified waste slag can be screened out for building material production; second, solid waste from the chemical industry, such as plastic waste, rubber fragments, and resin particles. Vibrating screens can achieve particle size grading, providing precise materials for subsequent recycling; third, waste from the mechanical processing industry, such as metal chips, waste grinding wheels, and waste castings. Impurities can be separated through vibrating screens to improve the purity of metal recycling.

It should be noted that when processing corrosive industrial waste, corrosion-resistant vibrating screens should be selected to avoid equipment damage.

4. Other Special Waste

In addition to the three main types of waste mentioned above, vibrating screens can also process agricultural waste (such as grading after straw crushing and screening after solidification of livestock and poultry manure) and medical waste (after high-temperature sterilization treatment, screening to remove large impurities for subsequent harmless landfill). This type of waste requires pre-treatment (such as crushing, solidification, and sterilization) to reduce viscosity and eliminate harmful components before being graded by vibrating screens, adapting to the refined needs of niche waste treatment scenarios. Furthermore, vibrating screens are not suitable for high-viscosity, easily agglomerating waste (such as undewatered sludge and highly adhesive waste paint residue). These materials tend to adhere to the screen mesh and clog the screen holes, leading to a significant decrease in screening efficiency.

B. Core Characteristics of Vibrating Screens for Waste Treatment

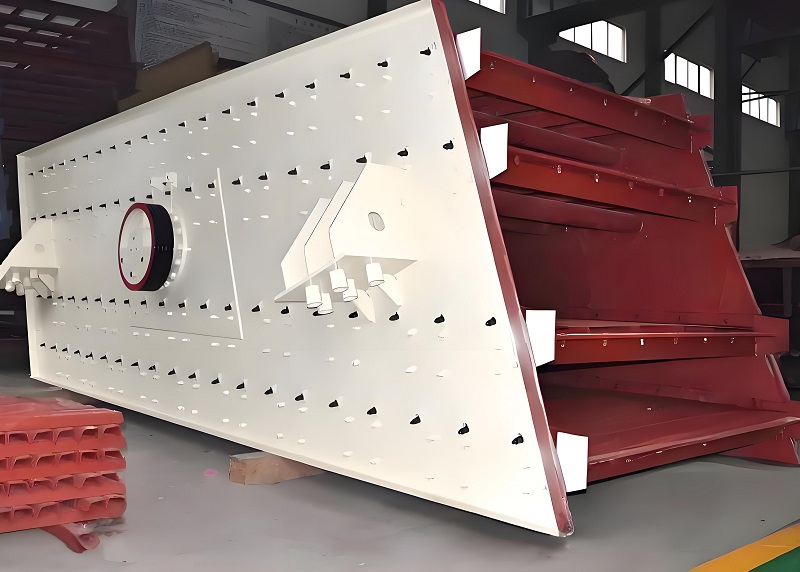

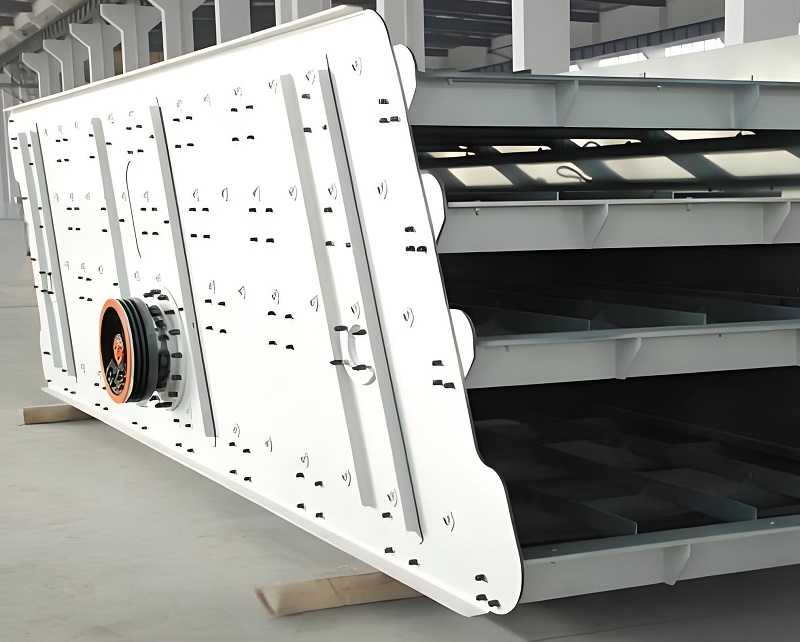

Considering the working conditions of waste treatment (complex materials, numerous impurities, and the need for continuous operation), vibrating screens possess strong adaptability, high screening efficiency, and stable operation. They also balance environmental protection and economic efficiency, meeting the practical needs of large-scale waste treatment.

1. Wide Range of Applications, Accommodating Various Waste Characteristics

Vibrating screens can be adapted to different particle sizes and hardnesses of waste by adjusting the screen mesh size, vibration frequency, and amplitude. They can handle both fine dust with particle sizes below 5mm and large pieces of waste with particle sizes exceeding 50cm (such as concrete blocks in construction waste). For waste with different moisture content, multi-layer screens and anti-clogging screen designs can be used to reduce agglomeration and clogging of wet materials. For hard waste (such as metal and mineral waste), wear-resistant screens and reinforced structures are used to improve equipment durability, meeting the needs of various waste treatment without frequent equipment replacement.

2. High Screening Efficiency and Controllable Grading Accuracy

Vibrating screens utilize a motor-driven eccentric block to generate high-frequency vibrations, causing the material to move back and forth on the screen surface. This significantly increases the contact area and frequency between the material and the screen, preventing material accumulation, and resulting in much higher screening efficiency than traditional screening equipment. In most cases, the waste screening efficiency can reach over 85%, and for dry, free-flowing waste (such as construction waste and dry industrial waste), the efficiency can be increased to over 90%.

At the same time, by using multi-layer screens (2-4 layers), multi-particle size grading can be achieved, accurately separating materials of different specifications to meet the differentiated needs of subsequent recycling and treatment. The grading accuracy error can be controlled within 5%, adapting to the development trend of refined waste treatment. 3. Compact Structure, Adaptable to Complex Operating Scenarios

Waste treatment sites often face challenges such as limited space and complex working conditions. The vibrating screen adopts a compact structural design, occupying a small footprint and allowing for flexible integration with crushing, sorting, and conveying equipment to form a streamlined operation system. This makes it suitable for various scenarios, including municipal solid waste transfer stations, construction waste recycling plants, and industrial waste treatment workshops. Furthermore, the equipment is easy to install and can be designed as either a fixed or mobile unit depending on site requirements. Mobile vibrating screens can be flexibly moved to the waste generation site (such as demolition sites), reducing waste transportation costs and improving processing efficiency.

4. Stable Operation and Low Maintenance Costs

Waste treatment requires continuous operation. The vibrating screen utilizes a mature vibration drive structure with good dynamic balance performance, resulting in low noise during operation (typically below 75 decibels). The vibration load transmitted to the foundation is small, reducing the likelihood of malfunctions and enabling 24-hour continuous operation. To address common problems in waste treatment, such as screen wear and material clogging, the equipment features a detachable screen for easy replacement and is equipped with screen cleaning devices (such as bouncing balls and ultrasonic cleaning) to reduce manual cleaning efforts.

In addition, the equipment's wear parts (screen mesh, eccentric blocks) are highly standardized, resulting in low procurement costs. Routine maintenance only requires periodic lubrication and tightening of components. The long-term operating and maintenance costs are lower than similar screening equipment, meeting the needs of large-scale, low-cost operations in the waste treatment industry.

5. Excellent Environmental Performance, Meeting Green Treatment Requirements

When processing waste, the vibrating screen can be equipped with a sealed screen box design to effectively reduce dust dispersion during the screening process and prevent secondary pollution. For wet waste, the vibration of the screen surface can separate some of the moisture, reducing energy consumption in subsequent processing (such as incineration) and minimizing wastewater discharge. Furthermore, precise screening improves the recycling rate of waste resources, reduces the total amount of waste for landfill and incineration, and contributes to achieving the goals of "reduction, resource utilization, and harmlessness" in waste treatment, complying with modern environmental protection policies. 6. High Flexibility and Customizable to Meet Specific Needs

The processing requirements for different types of waste vary significantly. Vibrating screens can be custom-designed based on actual working conditions. For example, for corrosive industrial waste, materials such as stainless steel and anti-corrosion coatings are used; for high-humidity food waste, the screen surface angle and vibration frequency are optimized to improve anti-clogging performance; and for large pieces of construction waste, the equipment structure is strengthened to adapt to heavy-duty screening requirements. Simultaneously, it can be integrated with an intelligent control system to achieve precise adjustment of vibration parameters, adapting to the screening needs of different types of waste.

With its wide range of waste adaptability and diverse performance advantages, the vibrating screen has become a core piece of equipment in the pre-treatment stage of waste processing, covering the grading and sorting needs of various types of waste, including household, construction, and industrial waste. It not only promotes the improvement of waste resource utilization but also provides efficient support for harmless treatment. Its efficient, stable, environmentally friendly, and flexible characteristics align with the development trend of large-scale, refined, and green waste treatment. As environmental protection technologies evolve, vibrating screens will further optimize anti-clogging, anti-corrosion, and intelligent performance, expanding their application scenarios and contributing to the high-quality development of the waste treatment industry, injecting continuous momentum into ecological environmental protection and resource recycling.