As a continuous conveying equipment with compact structure and stable conveying, the screw conveyor is widely used in many fields due to its unique working principle and performance characteristics. From grain storage to chemical production, from building materials transportation to food processing, the screw conveyor provides a reliable solution for material transportation in various industries with its strong practicality. Next, this article will explore the application fields of screw conveyors and their important role.

Application fields of screw conveyors

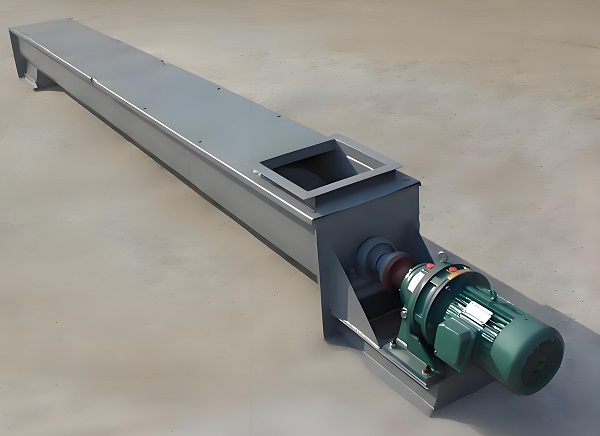

Screw Conveyor

1. Agricultural field

a. Grain storage and processing

In the grain storage link, screw conveyors are often used for grain in and out of the warehouse. Whether it is grains such as wheat and corn, or oil crops such as soybeans and rapeseed, screw conveyors can efficiently transport grain out of the granary or send newly harvested grain into the granary for storage. In grain processing enterprises, screw conveyors can transport the cleaned raw grain to processing equipment such as mills and oil presses, and can also collect and transport by-products such as bran and cakes produced during the processing process. For example, in a flour mill, the screw conveyor transports the cleaned wheat to the mill, and then transports the flour to the packaging workshop after grinding. The whole process is continuous and stable, which greatly improves production efficiency.

b. Feed production

In the process of feed production, multiple raw materials need to be mixed in a certain proportion. The screw conveyor undertakes an important material transportation task in the feed mill. It can transport raw materials such as corn, soybean meal, fish meal, additives, etc. from the storage bin to the mixer to ensure that various raw materials are accurately measured and evenly mixed. Due to the wide variety and different properties of feed raw materials, the screw conveyor can select the appropriate spiral blade form and conveying parameters according to the characteristics of different materials to ensure that the material does not get blocked or damaged during the conveying process, providing guarantee for the production of high-quality feed.

2. Industrial field

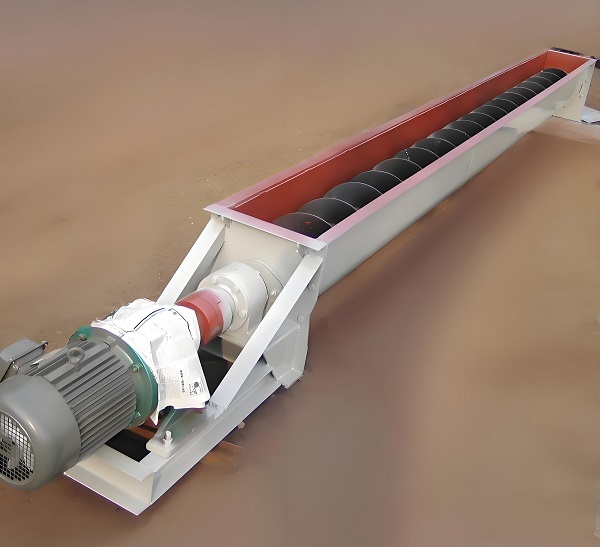

Screw Conveyor

a. Chemical industry

The chemical production process involves the transportation of a large amount of powdered and granular materials. The screw conveyor has become an ideal equipment for material transportation in the chemical industry due to its good sealing and low dust emission. In fertilizer production, powdered fertilizer raw materials such as urea and diammonium phosphate can be transported to granulation equipment; in the plastic processing industry, plastic particles can be transported from storage bins to extruders, injection molding machines and other molding equipment. In addition, for some corrosive or toxic and harmful chemical materials, the use of screw conveyors made of special materials (such as stainless steel, rubber lining, etc.), combined with material troughs and inlets and outlets with good sealing performance, can effectively prevent material leakage and ensure production safety and environmental friendliness.

b. Building materials industry

In the building materials industry, screw conveyors are widely used in the transportation of materials such as cement, fly ash, sand and gravel. In cement plants, screw conveyors transport finished cement from packaging machines to bulk warehouses or loading systems; in concrete mixing plants, powdered cement, fly ash and other materials can be transported to mixers, and sand and gravel aggregates can also be transported from storage bins to batching devices. Due to the large amount of building materials conveyed, screw conveyors usually adopt a large diameter and large conveying capacity design, and are equipped with wear-resistant spiral blades and troughs to adapt to long-term and high-intensity work requirements and ensure the continuous supply of building materials.

c. Mining industry

Ore, mineral powder and other materials generated during mining need to be transported efficiently. Screw conveyors can be used for short-distance ore transportation, such as transporting underground ore from the mining face to the lifting equipment, or transporting mineral powder in the beneficiation plant from the grinding equipment to the grading equipment. In the mining environment, screw conveyors need to have strong wear resistance and impact resistance, so thickened spiral blades and troughs are usually used, and the sealing performance of the equipment is strengthened to prevent dust from spilling, protecting the working environment and the health of operators.

3. Food industry

Screw Conveyor

a. Food processing

The food industry has extremely high hygiene requirements for material conveying equipment. Screw conveyors are made of stainless steel, with a smooth and easy-to-clean surface, which meets food hygiene standards, so they are widely used in the field of food processing. In biscuit production, screw conveyors can transport raw materials such as flour, sugar, and oil to mixers for mixing; in candy manufacturing, they can transport materials such as syrup and candy granules to molding equipment. In addition, screw conveyors can also be used in food packaging to transport packaged food from packaging machines to palletizers or warehouses to achieve automation and continuity in food production.

b. Food warehousing and logistics

In food warehousing and logistics, screw conveyors can be used for loading and unloading and handling of agricultural products such as grain, fruits and vegetables. For example, in large grain warehouses, screw conveyors transport grain from transport vehicles to granaries, or in fruit and vegetable processing enterprises, they transport washed fruits and vegetables to sorting and packaging workshops. By using closed screw conveyors, food can be effectively prevented from being contaminated during transportation, ensuring food quality and safety.

4. Environmental protection field

Screw Conveyor

a. Sewage treatment

In sewage treatment plants, screw conveyors are mainly used for the transportation and treatment of sludge. After sedimentation and concentration, the sludge has a certain viscosity and fluidity. The screw conveyor can transport the sludge from the sludge pool to the sludge dewatering machine, sludge drying equipment or sludge storage bin. Since the sludge contains corrosive substances and odor, the screw conveyor is usually made of anti-corrosion materials and equipped with sealing devices to prevent sludge leakage and odor emission, protecting the environment and the health of operators.

b. Garbage disposal

During the garbage disposal process, the screw conveyor can be used in the garbage conveying system of the garbage incineration power plant. The collected domestic garbage is transported to the incinerator. Through the push of the screw conveyor, it is ensured that the garbage can enter the incinerator evenly and continuously, thereby improving the incineration efficiency. In addition, in the landfill, the screw conveyor can also be used for the transportation of landfill cover soil, and the cover soil is evenly laid on the landfill layer to reduce the pollution of garbage to the environment.

The role of screw conveyors in various fields

Screw Conveyor

1. Improve material conveying efficiency

The continuous conveying characteristics of the screw conveyor can realize the uninterrupted transportation of materials, which greatly improves the material conveying efficiency compared with the traditional intermittent conveying method. In industrial production, it can work closely with other production equipment to form an automated production line, so that materials can be quickly and accurately transported from one production link to the next, reducing the waiting time of materials during the transportation process and improving the operating efficiency of the entire production system. In the agricultural field, the screw conveyor can quickly complete the transportation of grain in and out of the warehouse and the processing of raw materials, meeting the needs of strong seasonality and concentrated operation time in agricultural production.

2. Ensure the stability and accuracy of material transportation

The screw conveyor can ensure that the material maintains a uniform and stable flow rate during the transportation process through precisely designed spiral blades and stable speed control. In industries such as feed production and food processing, the ratio accuracy of materials is required to be high. The screw conveyor can accurately control the material delivery amount according to the requirements of the production process, ensure that various raw materials are mixed according to the set ratio, and thus ensure the stability of product quality. At the same time, the conveying process of the screw conveyor is relatively stable, and it is not easy to cause material spillage and accumulation, which reduces the loss and waste of materials.

3. Reduce labor intensity and labor costs

Screw Conveyor

The traditional material handling method often relies on manual operation, which is labor-intensive and inefficient. The application of screw conveyors realizes the mechanization and automation of material transportation. Operators only need to monitor and perform simple maintenance on the equipment, without directly participating in heavy material handling work, which greatly reduces labor intensity. At the same time, the automated conveying system reduces dependence on manual labor and reduces the labor cost of enterprises. This advantage is particularly obvious in large enterprises and production lines, which can save a lot of human resources and operating costs for enterprises.

4. Adapt to a variety of complex working conditions and material characteristics

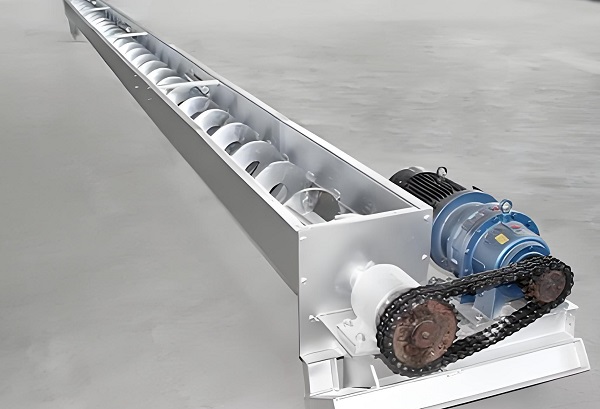

The screw conveyor has strong adaptability and can operate under different conveying distances, conveying angles and working environments. Whether it is horizontal conveying, inclined conveying or vertical conveying, the screw conveyor can meet the needs through reasonable design and configuration. In addition, it can also adapt to a variety of material characteristics, and can effectively convey powdery, granular, small blocks and even materials with a certain viscosity. In industries such as chemical and mining, facing special materials with corrosiveness and abrasion, the use of screw conveyors with special materials and structural designs can ensure the normal operation and service life of the equipment.

With its unique structure and working principle, the screw conveyor plays an irreplaceable and important role in many fields such as agriculture, industry, food, and environmental protection. With the continuous advancement of science and technology and the increasing requirements of various industries for material transportation, screw conveyors are also constantly innovating and developing, and will demonstrate their powerful functions and broad application prospects in more fields in the future.