As an important equipment for material transmission in industrial production, chain conveyor is widely used in many industries such as food, chemical industry, metallurgy, mining, etc. due to its large conveying capacity, wide application range and solid structure. However, in the long-term continuous operation process, chain conveyor will inevitably have various faults, affecting production efficiency and normal operation of equipment. Understanding the common fault types and causes of chain conveyor and mastering the corresponding maintenance methods are of great significance to ensure stable operation of equipment and reduce production costs.

Common fault types and causes of chain conveyor

1. Chain failure

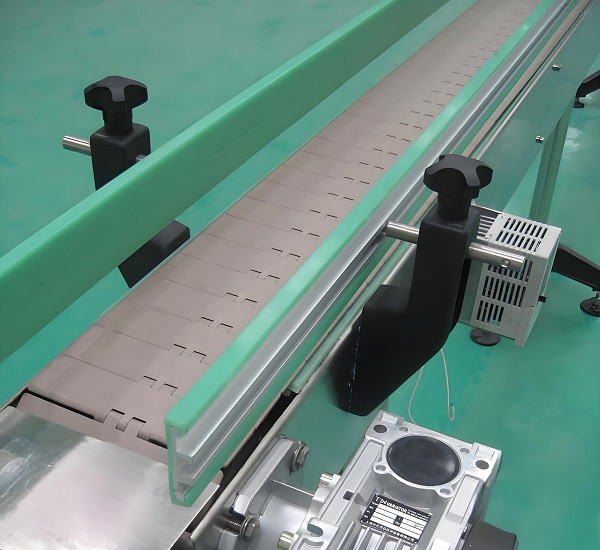

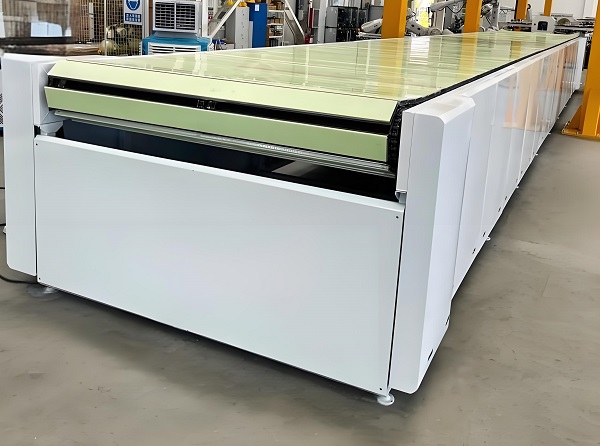

Chain Plate Conveyor

a. Chain wear

During the long-term operation, the chain is constantly rubbed against sprockets, guide rails and other parts, resulting in wear of chain links, chain pins and other parts. The main reasons for chain wear are: poor chain material and poor wear resistance; insufficient chain lubrication and increased friction coefficient; sharp particles in the conveyed material, aggravating chain wear; excessive or too small chain tension, causing uneven force on the chain and accelerated wear.

b. Chain tooth skipping

Chain tooth skipping means that the chain jumps out of the sprocket teeth when the chain is in operation. The main reasons include: the chain is severely worn and the pitch becomes longer, resulting in a decrease in the meshing accuracy between the chain and the sprocket; the sprocket wears unevenly and the tooth shape changes; the chain tension is insufficient and the chain is loose during operation; the center distance between the chain and the sprocket is inaccurate during installation, resulting in poor meshing.

c. Chain breakage

Chain breakage is a more serious fault that will cause the conveyor to stop suddenly and affect the production progress. The main reasons for chain breakage are: the chain has been subjected to excessive loads for a long time, exceeding its carrying capacity; there are defects in the chain material, such as cracks and slag inclusions inside; the chain is severely worn and the strength is reduced; during operation, the chain is subjected to sudden impact loads, such as material blockage and foreign matter stuck in.

2. Chain plate failure

Chain Plate Conveyor

a. Chain plate deformation

During the process of conveying materials, the chain plate may be deformed due to the gravity, friction and impact of the material during the conveying process. The reasons for the deformation of the chain plate are: the weight of the conveyed material exceeds the load-bearing capacity of the chain plate; the chain plate material is relatively soft and lacks strength; there is a deviation in the installation process of the chain plate, and the force is uneven; during the conveying process, the material is unevenly piled up, causing the chain plate to be locally overstressed.

b. Chain plate fracture

The chain plate fracture is usually caused by long-term exposure to large stress, or the chain plate itself has quality problems. Specific reasons include: the conveyed material contains sharp and hard objects, which cause impact and scratches on the chain plate, forming stress concentration points, causing the chain plate to break; the chain plate has defects in the manufacturing process, such as unqualified welding quality, pores inside the material, etc.; the chain plate is in a harsh environment such as high temperature and corrosion for a long time, and its performance and strength are reduced.

c. Loose chain plate connectors

The chain plates are fixed by bolts, pins and other connectors. During the operation of the conveyor, the connectors may loosen due to vibration, impact and other reasons. Loose connectors will cause the connection between the chain plates to be loose, affecting the normal transportation of materials, and may even cause serious accidents such as chain plate falling off. The main reasons for the loosening of the connectors are: the connectors are not tightened during installation; the vibration during operation is large, causing the connectors to gradually loosen; the material of the connector does not meet the requirements, the strength is insufficient, and it loosens under stress.

3. Failure of the drive device

Chain Plate Conveyor

a. Motor failure

The motor is the power source of the chain conveyor. Motor failure will directly cause the conveyor to fail to operate normally. Common motor failures include: motor overload. Due to excessive conveyor load, material blockage and other reasons, the motor current is too large, the heat is serious, and even the motor is burned; motor bearing damage. The bearing is worn out for a long time, poor lubrication or impact, which will cause bearing damage, causing abnormal noise and vibration when the motor is running; the motor winding is short-circuited or open-circuited. This may be caused by aging of the motor insulation, moisture, wiring errors, etc., which will cause the motor to fail to start normally or abnormalities during operation.

b. Reducer failure

The function of the reducer is to reduce the motor speed and increase the torque to meet the operating requirements of the conveyor. Common faults of reducers include: oil leakage of reducers, mainly due to aging and damage of seals, or uneven joint surface of the housing, which leads to lubricating oil leakage; wear of gears inside reducers, due to long-term operation, poor lubrication, gear material problems, etc., which will cause wear on the gear surface, affect transmission efficiency, and even cause gear breakage; damage to reducer bearings, similar to the causes of motor bearing damage, bearing wear, insufficient lubrication, etc., will cause abnormal noise and vibration during the operation of the reducer.

4. Tensioning device failure

Chain Plate Conveyor

a. Insufficient tensioning force

The function of the tensioning device is to maintain the proper tension of the chain. If the tensioning force is insufficient, the chain will relax, resulting in problems such as chain skipping and unstable operation. The main reasons for insufficient tensioning force are: the adjusting bolt of the tensioning device is loose, so that the tensioning force cannot be maintained; the tensioning spring fails due to fatigue and the elastic force decreases; the mechanical structure of the tensioning device fails, such as the screw rod is stuck, the nut is damaged, etc., resulting in the inability to adjust the tensioning force normally.

b. Excessive tension

Excessive tension will also have an adverse effect on the chain conveyor, increase the wear of components such as chains and sprockets, shorten the service life of the equipment, and even cause the chain to break. The main reason for excessive tension is that the operator did not adjust the tension device according to the prescribed tension standard, over-tightened the adjustment bolt or compressed the tension spring.

Common fault repair methods for chain conveyors

1. Chain fault repair

Chain Plate Conveyor

a. Chain wear treatment

When the chain wear is light, the wear rate can be slowed down by adjusting the chain tension and improving lubrication conditions. Apply appropriate lubricants to the chain regularly, such as high-temperature chain oil, to ensure that all parts of the chain are fully lubricated. If the chain is severely worn and the pitch elongation exceeds the specified range, a new chain needs to be replaced. When replacing the chain, you should choose a product with the same specifications and models as the original chain, and pay attention to the installation method and tension adjustment of the chain to ensure good meshing between the chain and the sprocket.

b. Chain skipping repair

For chain skipping faults, first check the wear of the chain and sprocket. If the wear is not serious, you can adjust the chain tension to restore the chain to the appropriate tightness and improve the meshing. If the sprocket is severely worn and the tooth shape changes significantly, you need to replace the sprocket; if the chain is severely worn, you should replace the chain and sprocket at the same time. When installing the chain and sprocket, make sure that the center distance between the two is accurate and the meshing between the chain and the sprocket is correct.

c. Chain break repair

After the chain breaks, stop the machine immediately and replace it with a new chain. When replacing the chain, pay attention to adjusting the length of the new chain to avoid the chain being too long or too short. At the same time, check the cause of the chain break, such as whether there is material blockage, foreign matter stuck, etc., and eliminate the hidden dangers of the fault in time to prevent the chain breakage accident from happening again.

2. Chain plate fault repair

Chain Plate Conveyor

a. Chain plate deformation repair

For slightly deformed chain plates, correction methods can be used to repair them. Use a special correction tool to apply appropriate pressure to the deformed part to restore it to its original shape. If the chain plate is severely deformed and cannot be repaired by correction, a new chain plate needs to be replaced. When replacing the chain plate, make sure that the specifications and materials of the new chain plate are the same as the original chain plate, and install the chain plate connector correctly to ensure a firm connection.

b. Replacement of chain plate fracture

A new chain plate must be replaced after the chain plate breaks. When replacing the chain plate, first stop the conveyor, loosen the chain, remove the broken chain plate, install the new chain plate and fix the connector. After the installation is completed, readjust the tension of the chain to ensure that the chain plate runs smoothly. At the same time, analyze the cause of the chain plate fracture and take corresponding preventive measures, such as screening the conveying materials, avoiding sharp and hard objects from entering the conveyor, and preventing the chain plate from breaking again.

c. Tightening of chain plate connectors

When the chain plate connector is found to be loose, stop the machine in time and check and tighten all connectors. Use appropriate tools to tighten bolts, pins and other connectors according to the specified torque. For severely worn or damaged connectors, replace new parts in time to ensure that the chain plate connection is firm and reliable.

3. Repair of drive device failure

a. Repair of motor failure

When the motor has an overload failure, first check whether the conveyor has material blockage, excessive load, etc. After troubleshooting, let the motor cool down for a while and restart it. If the motor bearing is damaged, it needs to be replaced with a new one. When replacing the bearing, pay attention to selecting the appropriate model and reliable quality products, and install them according to the correct installation method to ensure that the bearing is installed in place and well lubricated. For motor winding short circuit or open circuit failure, a professional electrician is required to inspect and find the fault point and repair or replace the winding. If the motor is seriously damaged and cannot be repaired, a new motor needs to be replaced.

b. Reducer fault handling

When the reducer leaks oil, first clean the leaking part and check whether the seal is aging or damaged. If the seal is damaged, replace it with a new one; if the joint surface of the box is uneven, it can be processed by grinding, applying sealant, etc. to ensure good sealing. When the internal gear of the reducer is severely worn, the worn gear needs to be replaced. When replacing the gear, pay attention to selecting products with the same specifications and models as the original gear, and perform correct installation and debugging to ensure good gear meshing. For the failure of the reducer bearing damage, the repair method is similar to the repair of the motor bearing damage. Replace the new bearing and lubricate it.

4. Tensioning device failure repair

Chain Plate Conveyor

a. Insufficient tension adjustment

If the tension is insufficient, first check whether the adjusting bolt of the tensioning device is loose. If the bolt is loose, tighten the adjusting bolt to make the chain reach the appropriate tension. If the tensioning spring fails due to fatigue, replace the new spring and adjust the compression of the spring to ensure that the tension meets the requirements. For mechanical structural failures of the tensioning device, such as screw rod jamming, nut damage, etc., it is necessary to repair or replace the faulty parts to restore the normal adjustment function of the tensioning device.

b. Adjustment of excessive tension

When the tension is too large, loosen the adjusting bolt or spring of the tensioning device to appropriately reduce the tension. In the process of adjusting the tension, use the tension measuring tool for detection to ensure that the tension is within the specified range. After the adjustment is completed, test the conveyor and observe the operation of the chain to ensure that the chain runs smoothly without tooth skipping, slipping, etc.

Maintenance and care of chain conveyor

1. Daily maintenance

a. Regular inspection

Inspect the chain conveyor every day, check the operation of the chain and chain plate, and observe whether there are abnormal phenomena such as wear, deformation, and breakage; check the working status of the drive device and tensioning device, check whether the operating temperature and noise of the motor and reducer are normal, and whether the tension is appropriate; check whether the connection of each component is firm, loose, or falling off.

b. Cleaning and lubrication

Regularly clean the materials, dust and other debris on the chain conveyor to keep the equipment clean. According to the requirements of the equipment manual, regularly apply lubricant to the moving parts such as chains, sprockets, and bearings to ensure good lubrication and reduce component wear.

2. Regular maintenance

Chain Plate Conveyor

a. Component replacement

Regularly replace wearing parts such as chains, chain plates, seals, bearings, etc. according to the operating time and wear of the equipment. Replace severely worn parts in time to avoid the expansion of equipment failures due to component damage.

b. System debugging

Regularly debug and calibrate the drive system and tensioning system of the chain conveyor to ensure that each system operates normally. Adjust the tension of the chain to keep it within the appropriate range; check the transmission ratio of the motor and reducer to ensure the stability of the conveying speed; inspect and maintain the electrical control system to ensure the safe operation of the equipment.

Common faults of chain conveyors involve many aspects. By understanding the fault type, cause and corresponding repair method, and doing daily maintenance and regular maintenance, the probability of faults can be effectively reduced, the service life of the equipment can be extended, and the smooth progress of industrial production can be guaranteed. In actual use, operators should strictly follow the operating procedures, deal with problems in a timely manner, and ensure that the chain conveyor is always in good operating condition.