As a key equipment for achieving continuous, uniform and quantitative supply of materials in industrial production, vibrating feeder is widely used in many fields such as mining, metallurgy, coal, building materials, chemical industry, etc. In the production line, it often connects the silo with the subsequent processing equipment to transport the materials at the set speed and flow rate to ensure the stability and order of the production process. However, under long-term high-load operation, vibrating feeder will inevitably have various faults, affecting production efficiency and product quality. Mastering its maintenance methods and daily maintenance skills is an important means to ensure stable operation of equipment and extend its service life.

Common fault analysis and maintenance of vibrating feeder

1. Abnormal vibration fault

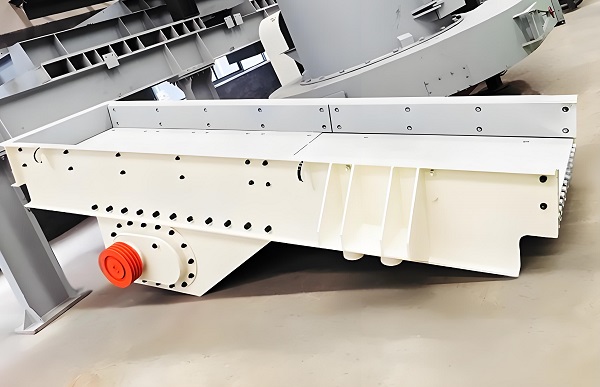

Vibrating Feeder

Fault phenomenon and cause

When the vibration of the vibrating feeder is abnormal, it may be manifested as unstable vibration amplitude, deviation of vibration direction or excessive vibration. The main reasons for this type of failure are: the eccentric block of the vibrator is not installed accurately or is not fixed firmly, the eccentric block is loose and shifted during operation, which destroys the balance of the vibration system; the spring of the spring support system is damaged, aged or has inconsistent elasticity, and cannot provide stable elastic support for the tank body; the coupling between the motor and the vibrator is not installed concentrically, which generates additional vibration and impact during operation; the equipment foundation is not installed firmly, and it shakes during operation, affecting the stability of the vibration.

Maintenance method

For the eccentric block problem, it is necessary to recheck the installation position and tightening of the eccentric block after stopping the machine, adjust the angle of the eccentric block according to the requirements of the equipment manual, use high-strength bolts to fix it firmly, and check the tightening degree of the bolts regularly at the beginning of the equipment operation. If the spring is damaged or the elasticity is inconsistent, the spring of the same specification and model should be replaced in time. When replacing, a group of springs should be replaced at the same time to ensure that the elastic properties of each spring are consistent. For the case of eccentric installation of the coupling, the coaxiality of the motor and the vibrator should be recalibrated, and tools such as dial indicators can be used for precise measurement and adjustment. If the equipment foundation is not firm, the foundation needs to be reinforced to ensure that the flatness and strength of the foundation meet the equipment operation requirements. If necessary, buffer devices such as shock-absorbing pads can be added to reduce the impact of equipment vibration on the foundation.

2. Unstable feeding amount failure

Vibrating Feeder

Failure phenomenon and cause

The unstable feeding amount is manifested as more or less material conveying, and it is impossible to feed evenly according to the set flow rate. The main reasons include: changes in the working parameters of the exciter, such as improper adjustment of the eccentric block angle, fluctuations in motor speed, etc., resulting in changes in vibration intensity and frequency, affecting the material conveying speed; changes in material properties, such as increased material humidity, uneven particle size, etc., which change the movement state of the material on the trough body, thereby affecting the feeding amount; wear, deformation or foreign matter blockage inside the feeding trough body, hindering the normal flow of materials; control system failure, such as sensor failure, controller parameter setting error, etc., cannot accurately control the operating state of the feeder.

Maintenance method

If the feeding amount is unstable due to changes in the working parameters of the exciter, it is necessary to readjust the eccentric block angle and motor speed, determine the appropriate working parameters through experiments, and strengthen the monitoring of parameters during the operation of the equipment. When the material characteristics change and affect the feeding amount, the equipment can be adjusted appropriately according to the material conditions, such as adding an arch-breaking device to solve the problem of material agglomeration, or adjusting the vibration frequency to adapt to materials of different humidity and particle sizes. For the wear and deformation of the feeding trough, minor wear can be repaired by welding wear-resistant materials, and severe deformation or wear requires the replacement of the trough; if there is foreign matter blocking, it should be stopped and cleaned in time. For control system failures, it is necessary to check the working status of the sensor, calibrate or replace the failed sensor; reset the controller parameters to ensure that it matches the actual operation requirements of the equipment.

3. Equipment noise is too loud

Vibrating Feeder

Failure phenomenon and cause

The abnormal noise generated by the vibrating feeder in operation will not only affect the working environment, but may also be an early warning signal of equipment failure. The main reasons for excessive noise are: the bearing of the vibrator is seriously worn or poorly lubricated, and the bearing produces friction noise when rotating at high speed; the spring and the connector of the spring support system are loose, and they collide with each other during operation to produce noise; the feed trough body rubs or collides with other parts, such as the gap between the trough body and the bracket and protective cover is too small; abnormal operation of the motor, such as motor bearing damage, rotor imbalance, etc., will also cause increased noise.

Maintenance method

For the bearing problem of the vibrator, it is necessary to check the lubrication of the bearing regularly, and replenish or replace the grease in time according to the equipment requirements; if the bearing is seriously worn, a new bearing should be replaced, and a reliable and suitable bearing model should be selected. Check the connection between the spring and the connector, tighten the loose bolts, and add a buffer gasket between the spring and the connector if necessary to reduce the collision noise. Adjust the gap between the feed trough body and other parts to ensure that the trough body does not rub or collide with the surrounding parts during the vibration process, and repair or replace the worn parts. If the motor is abnormal and causes increased noise, it is necessary to check the motor bearing and replace the damaged bearing; perform dynamic balancing test and correction on the motor rotor to ensure the smooth operation of the motor.

Daily maintenance of vibrating feeder

1. Cleaning and inspection

Vibrating Feeder

Daily cleaning

After the equipment is operated every day, the residual materials on the surface and inside of the feeding trough should be cleaned in time to prevent material accumulation and agglomeration, which will affect the normal operation and service life of the equipment. At the same time, clean the outer shell, protective cover and other parts of the equipment to keep the appearance of the equipment clean and tidy, and prevent dust and debris from entering the interior of the equipment, causing wear or blockage of the moving parts.

Regular inspection

Perform a comprehensive inspection of the vibrating feeder once a week to check whether the eccentric block, bolts and other parts of the exciter are loose, whether the spring is damaged or deformed, whether the feeding trough is worn or cracked, and whether the operating status of the motor and coupling is normal. During the inspection, if any problems are found in the parts, they should be handled in time to prevent the problems from expanding. In addition, the control system of the equipment needs to be checked to ensure that the sensors, controllers and other parts are working properly and the signal transmission is accurate.

2. Lubrication and maintenance

Lubrication management

Strictly follow the requirements of the equipment manual and regularly lubricate key parts such as the exciter bearings and motor bearings. Different types of bearings and working environments require different types of grease and lubrication cycles. Generally speaking, the lubrication cycle of the exciter bearing is shorter, and the grease needs to be added every 1-2 weeks and replaced every 3-6 months; the motor bearing can be added with grease every 3-6 months and replaced once a year. When adding or replacing grease, ensure that the quality and type of the grease meet the requirements to avoid bearing damage caused by using inferior grease.

Parts Maintenance

Regularly check the elastic properties of the spring. You can determine whether its elasticity is normal by measuring the compression and recovery of the spring. If the spring elasticity decreases or is damaged, it should be replaced in time. Anti-corrosion treatment is performed on the feeding trough, such as spraying anti-corrosion paint, to prevent the trough from rusting and damage due to material corrosion and environmental factors. At the same time, check the wear of the wear-resistant lining of the trough, and replace it in time if it is severely worn to extend the service life of the trough. In addition, it is necessary to regularly check the insulation performance of the motor to prevent the motor from malfunctioning or causing safety accidents due to poor insulation.

3. Standardized operation and records

Vibrating Feeder

Standardized operation

Operators should operate strictly in accordance with the equipment operating procedures. Before starting the equipment, check whether all parts of the equipment are normal and start only after confirming that there are no abnormalities. When starting, the motor should be started first, and feeding should be started after the equipment runs stably; when shutting down, feeding should be stopped first, and the motor should be turned off after the material in the tank is transported. Avoid the equipment from running under overload, no-load or abnormal conditions. It is strictly forbidden to adjust the working parameters of the equipment at will, such as the angle of the eccentric block, the speed of the motor, etc. When adjustment is necessary, it should be carried out under the guidance of professional technicians.

Operation record

Establish equipment operation record files, and record in detail the operating time, feeding amount, working parameters, fault conditions, and maintenance and maintenance of the vibrating feeder. Through the analysis of the operation records, potential problems in the operation of the equipment can be discovered in time, the operating rules of the equipment can be summarized, data support can be provided for the maintenance and maintenance of the equipment, and scientific management of the equipment can be realized.

The maintenance and daily maintenance of the vibrating feeder is a systematic and important work, which requires operators and maintenance personnel to have professional knowledge and a serious and responsible attitude. By timely and accurate fault repair and scientific and standardized daily maintenance, the operating stability and reliability of the vibrating feeder can be effectively improved, the equipment failure rate and maintenance costs can be reduced, and a strong guarantee can be provided for the production and operation of the enterprise.