With its unique working principle and significant performance advantages, the impact crusher occupies an important position in many fields such as mining, building materials, roads, and railways. A deep understanding of the working principle and application scenarios of the impact crusher will help to reasonably select and use equipment and improve production efficiency. Next, we will conduct a comprehensive and in-depth analysis of the impact crusher.

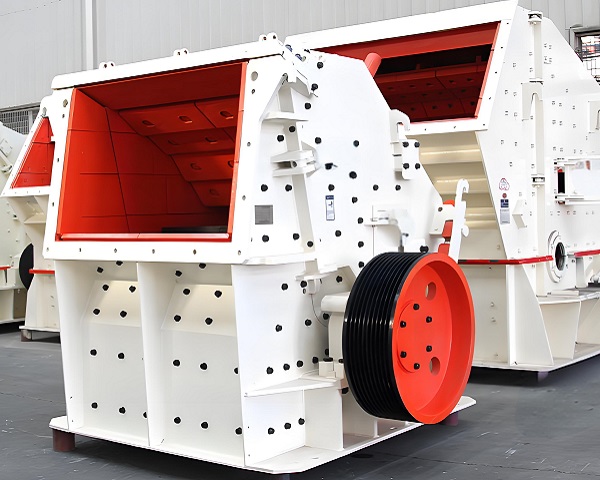

Impact Crusher

Structural composition of the impact crusher

The impact crusher is mainly composed of a frame, a rotor, an impact plate, a crushing chamber, an adjustment device, a transmission device, and a lubrication system. Each part cooperates with each other to complete the material crushing task.

1. Frame

The frame is the basic support structure of the impact crusher. It is usually welded with high-strength steel plates. It has good rigidity and stability and can withstand the huge impact force generated during the crushing process. The frame is divided into an upper frame and a lower frame. The upper frame can be opened by a hydraulic device or manually to facilitate the inspection and replacement of internal parts; the lower frame is fixed on the foundation to provide stable support for the entire equipment.

2. Rotor

The rotor is the core component of the impact crusher, which consists of the main shaft, hammer frame, hammer head, hammer shaft, etc. The main shaft is made of high-quality alloy steel and has sufficient strength and rigidity to withstand the centrifugal force and impact force generated by the high-speed rotation of the rotor. The hammer frame is installed on the main shaft and is distributed radially to fix the hammer head. The hammer head is a key part that directly contacts and crushes the material. It is usually made of wear-resistant materials such as high-chromium cast iron and high-manganese steel. Its shape and mass distribution have an important influence on the crushing effect. The hammer shaft connects the hammer head to the hammer frame so that the hammer head can swing freely around the hammer shaft.

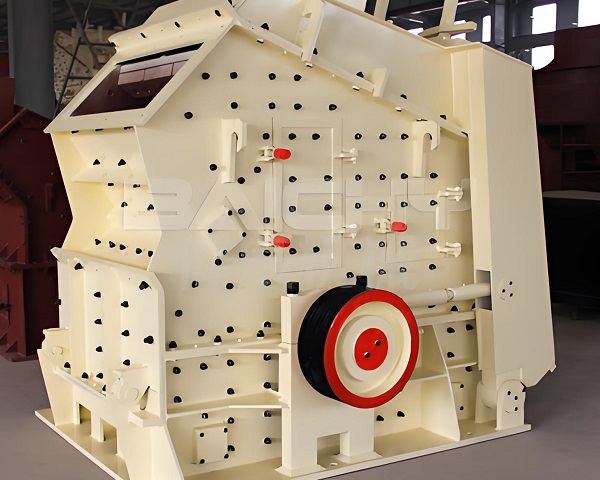

Impact Crusher

3. Counterattack plate

The counterattack plate is installed inside the frame and forms a crushing chamber with the hammer head on the rotor. Its function is to rebound the material ejected from the rotor, so that it collides, impacts and grinds with the hammer head and the counterattack plate again, thereby achieving further crushing of the material. The counterattack plate is generally made of high manganese steel or other high-strength wear-resistant materials. Its shape and angle can be adjusted according to the material properties and crushing requirements. Common counterattack plate shapes are broken line and arc.

4. Crushing chamber

The crushing chamber is the main area for material crushing, which is surrounded by the rotor, the impact plate and the guard plates on both sides. Its design shape and size determine the movement trajectory and residence time of the material in the chamber, which in turn affects the crushing efficiency and product particle size. Reasonable crushing chamber design can make the material be impacted and crushed multiple times in the chamber, improve the crushing ratio and product uniformity.

5. Adjustment device

The adjustment device is used to adjust the gap between the impact plate and the rotor to control the particle size of the product. Common adjustment methods include hydraulic adjustment and wedge adjustment. The hydraulic adjustment device pushes the impact plate forward and backward through the hydraulic system to achieve precise adjustment of the gap. The operation is convenient and fast, and it can be adjusted during the operation of the equipment; the wedge adjustment device changes the position of the impact plate by adjusting the position of the wedge. It has a simple structure and low cost, but it needs to be stopped for adjustment.

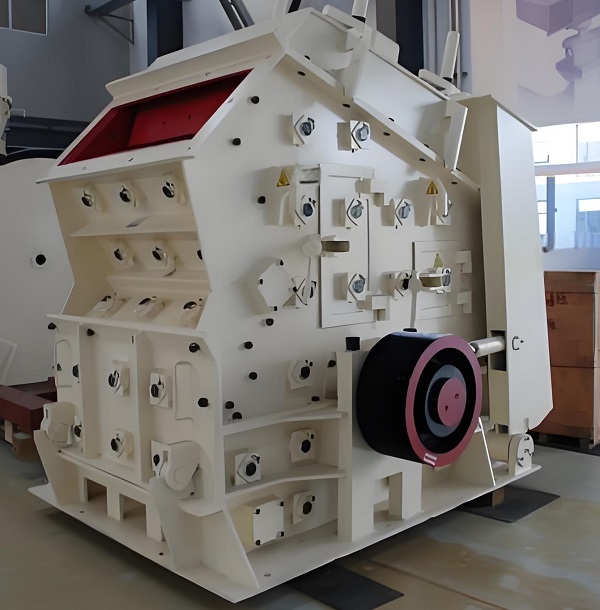

Impact Crusher

6. Transmission device

The transmission device is composed of a motor, a pulley, a belt, a transmission shaft, etc. Its function is to transmit the power of the motor to the rotor so that the rotor rotates at high speed. The motor is connected to the transmission shaft through a pulley and a belt. By adjusting the tension of the belt, the smoothness and reliability of the transmission can be ensured. The transmission shaft is connected to the rotor through a coupling, which transmits power to the rotor and drives the rotor to rotate at a set speed.

7. Lubrication system

The lubrication system provides lubrication for each moving part of the crusher, reduces friction and wear, reduces the operating temperature of the equipment, and extends the service life of the equipment. The lubrication system mainly includes components such as oil tanks, oil pumps, filters, oil pipes and oil nozzles. The lubricating oil is transported to various lubrication points through the oil pump to lubricate and cool key parts such as bearings and journals.

Working principle of impact crusher

Impact Crusher

The working principle of impact crusher is based on impact crushing theory. When the equipment is started, the motor drives the rotor to rotate at high speed through the transmission device, and the hammer installed on the rotor also moves at high speed. After the material enters the crushing chamber from the feed inlet, it is first impacted by the high-speed rotating hammer and crushed into smaller particles. Under the action of inertia, these crushed particles hit the impact plate at high speed, collide with the impact plate and rebound, and collide, impact and grind with the hammer head or other materials on the rotor again. In this process, the material is continuously crushed and refined until its particle size meets the requirements and is discharged from the discharge port at the bottom of the crusher.

During the entire crushing process, the material undergoes multiple impacts, collisions and grinding. This crushing method makes the material crushing ratio large, the product particle size is uniform, and it is mostly cubic in shape, with less needle-like content, which is very suitable as a high-quality building aggregate. At the same time, since the crushing process of the impact crusher mainly relies on impact force, compared with the extrusion crusher, its energy utilization rate is higher and the energy consumption is relatively low.

Application field of impact crusher

Impact Crusher

1. Mining industry

In mining, impact crusher is often used for medium and fine crushing of ore. For example, in metal mines, it can crush the mined raw ore to a suitable particle size for subsequent mineral processing. For iron ore, copper ore, lead-zinc ore, etc., impact crusher can effectively crush them, improve the dissociation degree of ore, and help improve the recovery rate of mineral processing. In non-metallic mines, such as limestone mines and quartz mines, impact crusher can crush ore into finished products of different particle sizes to meet the requirements of raw material particle size in the construction, chemical and other industries. In addition, impact crusher also plays an important role in the treatment of mine tailings. Through the crushing and reprocessing of tailings, the comprehensive utilization of tailings can be achieved, and the pressure on the environment caused by tailings accumulation can be reduced.

2. Building materials industry

In the building materials industry, impact crusher is a key equipment for the production of building aggregates. It can crush various rocks such as limestone, dolomite, granite, basalt, etc. into crushed stone and machine-made sand of different specifications for the production of concrete, asphalt mixture, cement products, etc. Because the aggregate produced by impact crusher has good particle shape and reasonable gradation, it can improve the strength and durability of concrete, so it is widely used in the construction of large-scale infrastructure such as high-rise buildings, roads and bridges, and water conservancy projects. In addition, impact crushers can also be used for raw material processing in the production of building materials such as bricks, tiles, and ceramics, crushing the raw materials to a suitable particle size to improve product quality and production efficiency.

Impact Crusher

3. Highway and railway construction

In highway and railway construction, high-quality building aggregates are the key to ensuring project quality. The aggregates produced by the impact crusher have good particle shape and gradation, and can meet the quality requirements of highway pavement base, subbase, and railway ballast. In highway construction, the impact crusher can crush stones into crushed stones of different specifications for paving the pavement base and subbase to improve the bearing capacity and stability of the pavement. In railway construction, the crushed stones it produces can be used as railway ballast to provide stable support for the rails and ensure the safe operation of trains. In addition, impact crushers can also be used for the crushing and recycling of waste concrete and asphalt pavements in highway and railway construction, crushing the waste materials and reprocessing them into aggregates for new engineering construction, realizing the recycling of resources and reducing engineering costs.

4. Urban construction waste treatment

With the acceleration of urbanization, the amount of urban construction waste is increasing. Impact crusher has important application value in the treatment of urban construction waste. It can crush and screen concrete blocks, bricks, tiles, stones, etc. in construction waste and process them into recycled aggregates of different particle sizes. These recycled aggregates can be used to produce recycled bricks, recycled concrete, road base materials, etc., to achieve the reduction, resource utilization and harmless treatment of construction waste. By using impact crusher to treat construction waste, it can not only reduce the pollution of construction waste to the environment, but also provide a large amount of recycled resources for urban construction, alleviate the problem of shortage of natural sand and gravel resources, and have significant economic and environmental benefits.

5. Chemical industry

Impact Crusher

In the chemical industry, impact crusher can be used for crushing and processing various chemical raw materials. For example, in fertilizer production, it can crush raw materials such as phosphate ore and potash ore to a suitable particle size for subsequent chemical reactions and processing. In rubber, plastic and other industries, impact crusher can crush waste rubber, plastic, etc. to provide raw materials for recycling. In addition, in the production process of some chemical products, the raw materials need to be crushed into fine particles to improve the reaction rate and product quality. The impact crusher can meet these production needs and provide strong support for the production of the chemical industry.

The impact crusher plays an important role in many industries with its unique working principle and significant performance advantages. Although it has some limitations, these problems will be gradually solved with the continuous advancement and innovation of technology. In the future, the impact crusher will develop in a more efficient, energy-saving, environmentally friendly and intelligent direction, making greater contributions to industrial production and social development.