In many industrial fields such as ore mining and construction aggregate production, hammer crushers have become key equipment in the material crushing process due to their efficient crushing capacity and wide applicability. However, there are many types of hammer crushers on the market with uneven performance. How to choose high-quality equipment that meets their own production needs has become an important issue faced by enterprises and practitioners. The purchase of hammer crushers requires comprehensive consideration of equipment performance, quality reliability, operating costs and other factors. The following will elaborate on the skills and main matters of purchase from multiple dimensions.

Clarify your own production needs

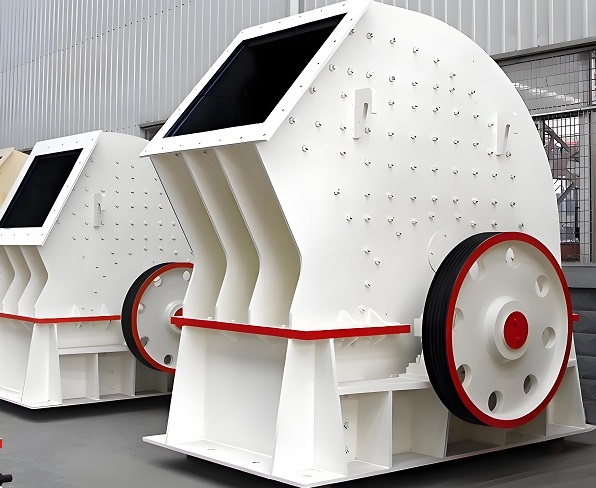

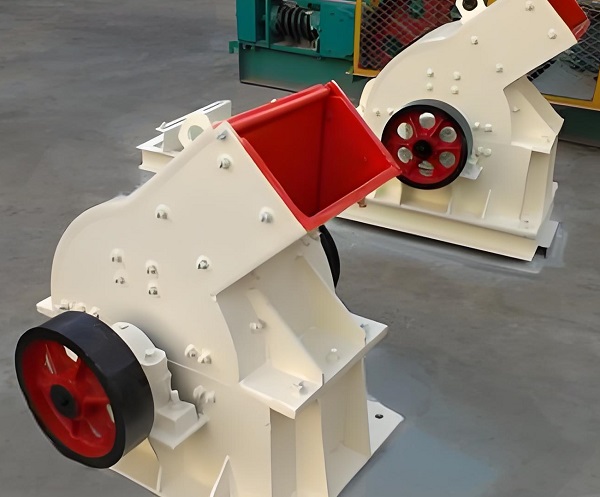

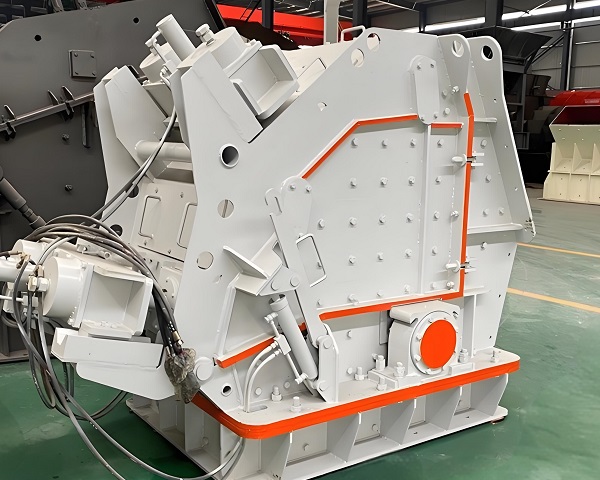

Hammer Crusher

1. Processing material characteristics

Material type and hardness: Different materials have different hardness and physical properties, which directly affect the selection of hammer crushers. For example, medium and low hardness materials such as limestone and gypsum have relatively little wear on the crusher, and conventional models of hammer crushers can be selected; while materials with higher hardness such as quartz stone and granite will cause greater wear on the hammer head, liner and other components of the crusher during the crushing process, and hammer crushers equipped with high wear-resistant material components and stronger crushing force need to be selected. If the hardness of the materials varies greatly, it is also necessary to consider whether the equipment has the ability to flexibly adjust the crushing parameters.

Material humidity: Material humidity will affect its fluidity and crushing difficulty. When handling materials with high humidity, such as clay, wet sand, etc., it is easy for the materials to adhere to the crushing chamber, causing blockage and affecting the crushing efficiency. Therefore, for materials with high humidity, a hammer crusher with anti-blocking design should be selected, such as increasing the size of the feed port, optimizing the structure of the crushing chamber, and adding a discharge port cleaning device to ensure that the material can pass through the crushing chamber smoothly and avoid equipment shutdown and production interruption due to blockage.

Material particle size: Understanding the maximum particle size and particle size distribution of the material to be crushed is crucial to determining the feed port size and crushing ratio of the hammer crusher. If the feed particle size is large, it is necessary to select equipment with a wide feed port and a large crushing ratio to ensure that the material can enter the crusher smoothly and be crushed to the appropriate particle size at one time, reducing the energy consumption and cost increase caused by secondary crushing.

Hammer Crusher

2. Production scale and capacity requirements

Processing volume requirements: According to the company's production plan and expected output, accurately calculate the required material processing volume. The capacity of a hammer crusher is usually measured by the weight of material processed per hour (tons/hour). When purchasing, you should ensure that the rated capacity of the equipment is slightly greater than the actual demand to cope with fluctuations in the production process and processing needs during peak hours. For example, for large-scale mining companies, the processing volume may reach hundreds of tons per hour, and a large-scale, high-capacity hammer crusher needs to be selected; while for small processing plants, the processing volume is relatively small, and small and medium-sized equipment can be selected.

Continuous working time: Considering the continuous working time of the equipment is also key. If production requires long-term uninterrupted operation, such as large stone production lines, which work up to 16 hours or even longer a day, then the stability and reliability of the equipment are particularly important. You should choose a hammer crusher with a good heat dissipation system, a sturdy and durable mechanical structure, and the ability to withstand long-term high-load operation. At the same time, pay attention to the convenience of replacing the equipment's wearing parts to reduce downtime and maintenance time and ensure production continuity.

Pay attention to the core performance indicators of the equipment

Hammer Crusher

1. Crushing ratio and crushing efficiency

Crushing ratio: Crushing ratio refers to the ratio of the crusher's feed particle size to the discharge particle size, reflecting the degree of crushing of the material by the crusher. Different types of hammer crushers have different crushing ratios. Generally speaking, the larger the crushing ratio, the finer the crusher can crush the material. When purchasing, you need to choose equipment with a suitable crushing ratio according to the actual production requirements for product particle size. For example, if you need to produce fine-grained building aggregates, you should choose a hammer crusher with a large crushing ratio; if you only need to perform coarse crushing pretreatment, equipment with a moderate crushing ratio can meet the needs.

Crushing efficiency: Crushing efficiency is not only related to the crushing ratio, but also affected by many factors such as the structural design, rotation speed, and power system of the equipment. Efficient hammer crushers usually have a reasonable crushing cavity shape, optimized hammer arrangement and motion trajectory, which can fully impact, collide and grind the material in the crushing cavity, thereby improving the crushing efficiency. When purchasing, you can refer to the technical parameters and actual production cases provided by the equipment manufacturer to understand the crushing efficiency performance of the equipment under the same working conditions, and give priority to products with high efficiency.

2. Power system and energy consumption

Motor power matching: The motor power of the hammer crusher must match the crushing capacity and production requirements of the equipment. If the power is too small, the equipment may not achieve the expected crushing effect and production capacity, and may even cause problems such as stalling and overload; if the power is too large, it will cause energy waste and increase operating costs. When selecting the motor power, it should be comprehensively calculated based on factors such as material characteristics, processing volume and crushing ratio, and consult the professional advice of the equipment manufacturer to ensure that the motor power can meet production needs and achieve energy-saving operation.

Energy consumption level: Energy consumption is an important part of the equipment operating cost. Choosing a low-energy hammer crusher can effectively reduce long-term production costs. Modern and efficient hammer crushers usually use advanced transmission technology, optimized motor design and reasonable structural layout to improve energy utilization. When purchasing, you can compare the energy consumption data of equipment from different manufacturers and different models, and pay attention to whether the equipment has energy-saving technology, such as variable frequency speed regulation function, which can automatically adjust the motor speed according to the material processing volume to reduce unnecessary energy consumption.

Hammer Crusher

3. Quality and life of wearing parts

Hammer material and wear resistance: The hammer is the most critical wearing part of the hammer crusher. Its quality and wear resistance directly affect the crushing effect and service life of the equipment. Common hammer materials include high manganese steel, high chromium cast iron, composite materials, etc. High manganese steel has good toughness and work hardening properties. When impacted, the surface will harden quickly and improve wear resistance; high chromium cast iron has high hardness and good wear resistance, but relatively poor toughness; composite hammer combines the advantages of high manganese steel and high chromium cast iron, and has good toughness and wear resistance. When purchasing, it is necessary to select a hammer of suitable material according to the characteristics of the processed materials and production conditions, and understand the manufacturer's production process and quality control standards to ensure the wear resistance and reliability of the hammer.

Lining and other vulnerable parts: In addition to the hammer, the lining and screen plates of the crushing chamber are also vulnerable parts, which will be impacted and worn by the material during the crushing process. High-quality linings and screen plates should have good wear resistance and impact resistance, which can effectively protect the chamber structure of the crusher and extend the service life of the equipment. When purchasing, you need to check the material, thickness and manufacturing process of these wearing parts, and understand the manufacturer's wearing parts supply and price, so as to avoid affecting production due to high replacement costs or untimely supply of wearing parts.

Consider equipment quality and reliability

Hammer Crusher

1. Manufacturer's strength and reputation

Manufacturer qualifications and technical level: Choosing a manufacturer with good qualifications and technical strength is the key to ensuring equipment quality. You can understand the manufacturer's legal compliance and production management level by checking the manufacturer's business license, production license, quality management system certification and other relevant qualification documents. At the same time, pay attention to the manufacturer's R&D capabilities and technological innovation achievements, such as whether it has patented technology, whether it participates in the formulation of industry standards, etc. Manufacturers with strong R&D capabilities can usually provide equipment with more advanced performance and more reliable quality.

Market reputation and user evaluation: Understanding the manufacturer's market reputation and user evaluation can intuitively reflect the actual use effect and after-sales service quality of the equipment. You can collect other users' evaluations of the manufacturer's equipment through online searches, industry forums, peer exchanges, etc., including equipment stability, reliability, life of wearing parts, after-sales service response speed and other aspects. Priority should be given to products from manufacturers with a good reputation in the industry and high user satisfaction.

2. Equipment manufacturing process and quality control

Processing accuracy and assembly process: The manufacturing process of the hammer crusher directly affects the operating stability and reliability of the equipment. High-quality equipment usually uses advanced processing equipment and precision processing technology to ensure the processing accuracy of parts. For example, the processing accuracy of the spindle affects the dynamic balance performance of the rotor. If the spindle processing error is large, it will cause the vibration of the equipment to intensify during operation and shorten the life of the equipment; the assembly accuracy and balance of the hammer head also have an important impact on the crushing effect and equipment stability. When purchasing, you can ask the manufacturer to provide the processing technology description and quality inspection report of the equipment parts to understand the manufacturing process level of the equipment.

Quality control system: A complete quality control system is an important link to ensure the quality of equipment. Formal manufacturers should have a full-process quality control process from raw material procurement, parts processing, assembly and debugging to finished product inspection, and conduct strict quality inspection and control for each production link. When purchasing, you can ask the manufacturer's quality control measures and inspection standards to check whether the equipment has passed relevant quality certifications, such as ISO 9001 quality management system certification, to ensure that the equipment meets quality requirements.

Attach importance to after-sales service and technical support

Hammer Crusher

1. After-sales service content and response speed

After-sales service items: High-quality after-sales service should cover equipment installation and commissioning, operator training, regular maintenance, fault repair and other aspects. Equipment installation and commissioning can ensure the correct installation and smooth operation of the equipment, and reduce faults caused by improper installation; operator training can enable staff to master the operation methods and maintenance points of the equipment, improve the efficiency and safety of equipment use; regular maintenance can timely discover and solve potential problems of the equipment and extend the service life of the equipment; fast and effective fault repair can reduce equipment downtime and production losses. When purchasing, it is necessary to understand the manufacturer's after-sales service content and commitments in detail to ensure that you can get comprehensive service support.

Response speed: The response speed of after-sales service is directly related to the downtime of equipment failure. In the production process, once the equipment fails, it is very important to get timely maintenance support from the manufacturer. You should choose a manufacturer with a wide coverage of after-sales service network and timely response, and understand whether the manufacturer has after-sales service outlets in the local or surrounding areas, and the average response time after the fault is reported. Priority should be given to manufacturers who can arrive at the site for repair within 24 hours to ensure the continuity of production.

2. Technical support and accessories supply

Technical support capabilities: In addition to after-sales service, the manufacturer's technical support capabilities should not be ignored. During the operation of the equipment, various technical problems may be encountered, such as process parameter adjustment, equipment optimization and upgrading, etc., which require the manufacturer to provide professional technical guidance and solutions. Manufacturers with strong technical support capabilities can provide personalized technical services according to the actual needs of users to help users improve equipment operation efficiency and production benefits. When purchasing, you can understand the scale and professional level of the manufacturer's technical team, as well as whether they can provide regular technical training and technical consulting services.

Accessory supply guarantee: Ensuring the timely supply of wearing parts and other accessories is an important guarantee for the normal operation of the equipment. When purchasing a hammer crusher, you need to understand the manufacturer's accessories supply, including whether the types of accessories are complete, whether the price is reasonable, and whether the supply cycle meets the needs. Choose a manufacturer with sufficient accessories supply, transparent prices, and short supply cycles to avoid equipment downtime due to accessories shortages, while reducing accessories procurement costs.

Comprehensive evaluation of price and cost performance

Hammer Crusher

Price is a factor that must be considered when purchasing a hammer crusher, but price cannot be the only criterion for selection. Low-priced equipment may have deficiencies in quality, performance and after-sales service, and may generate higher maintenance and operating costs during later use, which will increase the overall investment; and overpriced equipment may not fully meet actual needs, and may have redundant functions. Therefore, while paying attention to the price, the performance, quality, after-sales service and other factors of the equipment should be comprehensively considered to conduct a cost-effectiveness analysis. By comparing the prices and comprehensive performance of equipment from different manufacturers and different models, a hammer crusher that can meet production needs and has a high cost performance can be selected to maximize economic benefits.

Purchasing a hammer crusher is a comprehensive decision-making process. It is necessary to start from one's own production needs and comprehensively consider the core performance, quality reliability, after-sales service and price of the equipment. Only through in-depth research, multi-party comparison, and comprehensive evaluation combined with actual production conditions can a hammer crusher with excellent performance, reliable quality and high cost performance be purchased to provide strong guarantees for the production and operation of the enterprise and enhance the market competitiveness and economic benefits of the enterprise.