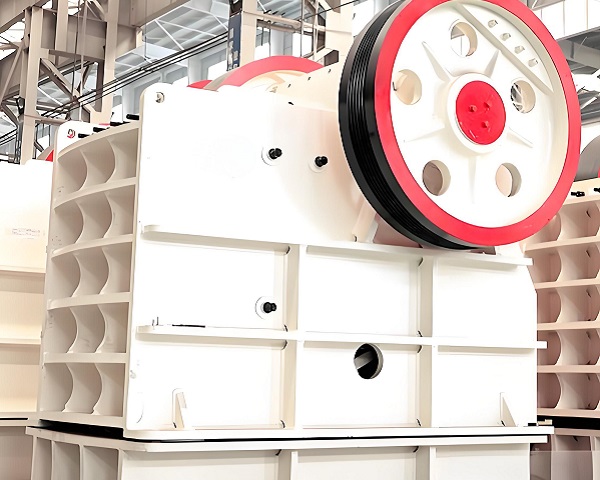

Jaw crushers are key equipment in the crushing industry, and their stable operation directly impacts production efficiency and costs. Proper jaw crusher maintenance and routine upkeep can effectively extend equipment life and reduce downtime. The following details key jaw crusher maintenance points and routine maintenance methods.

Jaw Crusher Maintenance

A. Common Faults and Repair Methods

Jaw crushers are bound to experience various faults during long-term operation, making timely and accurate diagnosis and repair crucial.

1. Bearing Overheating: This is a common jaw crusher fault. Overheating is considered a problem when the bearing temperature exceeds 70°C. Causes of bearing overheating may include poor lubrication (i.e., insufficient or poor-quality lubricant); excessive bearing clearance (increased friction); or bearing damage. If bearing overheating is detected, first check the lubricant and add or replace the appropriate lubricant. If the problem persists, check the bearing clearance and replace the bearing if necessary.

2. Coarsening of the crushed product: This may indicate excessive clearance between the movable and fixed jaws. This clearance can be reduced by adjusting shims or wedges. Alternatively, the jaw plates may be severely worn, requiring replacement.

3. Severe machine vibration: This may be due to loose foundation bolts, which should be tightened promptly. It may also be due to rotor imbalance; check for loose or unevenly worn rotor parts and perform balancing adjustments. Alternatively, hard objects such as iron may have entered the material, requiring machine shutdown and cleaning.

B. Inspection of Key Components

1. Jaw Plate: The jaw plate is the component of the jaw crusher that directly crushes the material and wears rapidly. Regularly inspect the jaw plate for wear and replace it when wear reaches a certain level. Ensure it is securely installed and fits snugly against the jaw body to prevent loosening or shaking during the crushing process.

2. Bearings: Bearings are critical rotating components of the jaw crusher, and their performance directly impacts the operation of the equipment. Regularly inspect the bearings for abnormal noise, overheating, or oil leakage. If a bearing is found to be damaged, it should be replaced promptly. When replacing, select a bearing that matches the original model and ensure proper installation.

3. Eccentric Shaft: The eccentric shaft is a key component that drives the movable jaw and bears heavy loads. Inspect the eccentric shaft for defects such as bends and cracks. If found, repair or replace it promptly. Also, check the fit between the eccentric shaft and the bearing to ensure proper operation.

C. Daily Maintenance of Jaw Crusher

1. Pre-Startup Inspection

Before starting up, a comprehensive inspection of the jaw crusher must be performed to ensure safe and normal operation.

Check that all connecting bolts, including those on the frame, jaw plate, and bearing seat, are tight. Tighten any loose bolts promptly.

Check the lubrication system to ensure sufficient lubricating oil, good quality, and unobstructed oil flow. Add or replace lubricating oil if necessary.

Inspect the crushing chamber and remove any debris, such as iron or rocks, to prevent damage during startup. Check the transmission system to see if the belt is properly tight and whether the pulleys are misaligned. If any problems arise, adjust them promptly.

2. Monitoring During Operation

During the operation of the jaw crusher, closely monitor the equipment's operating status to promptly detect and address any abnormalities.

Pay attention to the equipment's operating sound. During normal operation, it should produce a uniform and steady sound. If any abnormal noises, such as banging or squealing, occur, immediately stop the machine for inspection.

Monitor the equipment's temperature. Regularly measure the temperatures of the bearings, motor, and other components to ensure they are within normal ranges. Generally, bearing temperatures should not exceed 70°C, and motor temperatures should not exceed the rated temperature.

Observe the particle size of the crushed product. If the particle size does not meet the requirements, adjust the clearance between the movable and fixed jaws promptly.

Pay attention to the equipment's vibration. If excessive vibration occurs, stop the machine and investigate the cause.

3. Maintenance After Shutdown

Performing proper maintenance on the jaw crusher after shutdown can effectively extend its service life.

Clean the crushing chamber to remove any remaining material to prevent it from solidifying or agglomerating. Inspect the wear of various components, such as the jaw plate, bearings, and belts, and keep records to facilitate subsequent repairs and replacements.

Maintain the lubrication system by draining the lubricant, cleaning the oil tank and oil lines, and then adding new lubricant.

Clean the equipment surface to remove dust, oil, and other debris, and keep the equipment clean and tidy.

4. Maintenance Precautions

Operators must receive professional training and be familiar with the performance and operation of the jaw crusher. They must strictly follow the operating procedures during operation and maintenance.

Perform a comprehensive inspection and maintenance of the equipment regularly, develop a reasonable maintenance plan, and strictly adhere to it.

When replacing parts, select products of qualified quality and the correct model to ensure the performance and safety of the equipment.

Maintain maintenance records, detailing the equipment's operating conditions, maintenance details, and replaced parts for traceability and analysis.

Repair and routine maintenance of a jaw crusher is a systematic and meticulous process. Only by doing this properly can you ensure stable equipment operation, improve production efficiency, and reduce production costs.