In modern industrial production, cone crushers are widely used in many fields such as mining, metallurgy, building materials, highways, railways, water conservancy and chemical industries due to their advantages of large crushing ratio, high efficiency, low energy consumption and uniform product particle size. They are key equipment for material crushing and processing. However, since cone crushers are operated under high load and harsh conditions for a long time, various faults will inevitably occur, affecting the normal operation of the equipment and production progress

Common faults and repairs of cone crushers

1. Mechanical failure

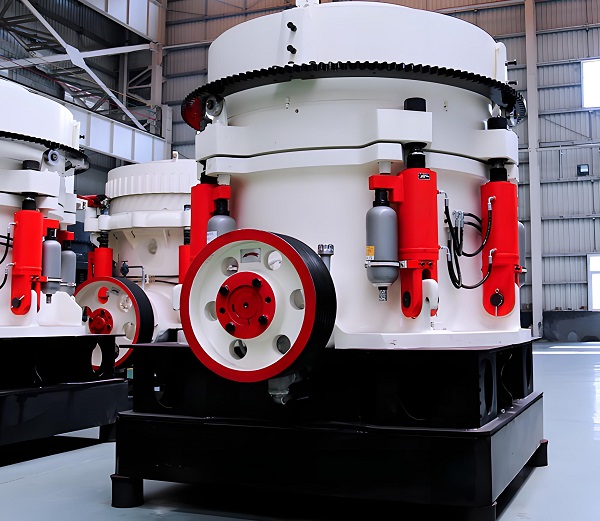

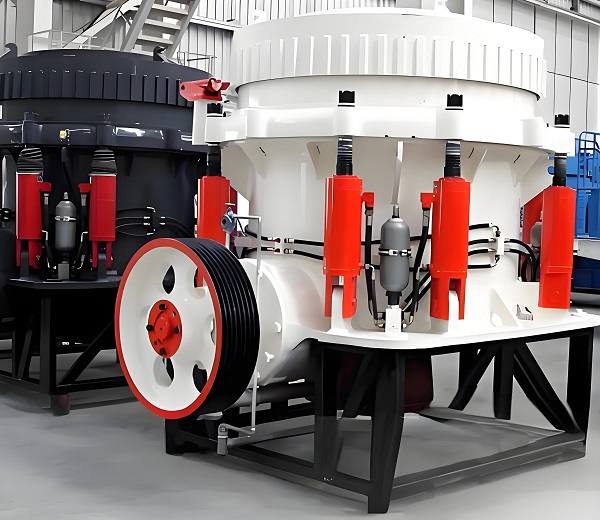

Cone Crusher

a. The moving cone and fixed cone linings wear too fast

Fault phenomenon: Severe wear, grooves or peeling on the surface of the lining plate lead to an increase in the size of the discharge port, a coarser product particle size and a decrease in the production capacity of the crusher.

Causes: Material properties do not meet the requirements, such as too large particle size, too high hardness, containing a large number of sharp edges or corrosive substances; uneven feeding, resulting in excessive local force on the liner; the eccentricity of the crusher is too large or the speed is too fast, which intensifies the impact and friction between the liner and the material; poor lubrication, the heat generated by the friction between the moving cone and the main shaft is transferred to the liner, accelerating the wear of the liner; the liner material is not good or the installation quality is poor, the liner and the moving cone and the fixed cone are not tightly fitted, and relative sliding occurs during the crushing process.

Maintenance method: strictly control the particle size and properties of the material to prevent materials that do not meet the requirements from entering the crusher; adjust the feeding device to ensure uniform and continuous feeding; reasonably adjust the eccentricity and speed of the crusher according to the material properties and production requirements; strengthen the maintenance of the lubrication system, regularly check the quality and amount of the lubricating oil, and replace the deteriorated or contaminated lubricating oil in time to ensure good lubrication effect; select reliable quality and good wear-resistant liner materials, ensure that the liner fits tightly with the moving cone and the fixed cone during installation, and use high-strength bolts or special fixing methods to fix the liner when necessary. For severely worn linings, they should be replaced in time.

b. Abnormal vibration of the crusher

Fault phenomenon: The crusher vibrates violently during operation, and the vibration amplitude exceeds the normal range, which may be accompanied by abnormal noise. In severe cases, it may cause the equipment foundation to loosen and parts to be damaged.

Cause: Uneven material feeding leads to unbalanced material distribution in the crushing chamber; non-crushed objects, such as iron blocks and stones, enter the crusher, causing uneven force on the moving cone; the clearance between the main shaft and the moving cone is too large or too small, affecting the stability of the moving cone; the bearing is severely worn, the clearance increases, and the vibration of the rotating parts is aggravated; the equipment foundation is not firmly installed, the anchor bolts are loose or the foundation pad is displaced; the belt tension of the belt drive device is uneven or the belt is severely worn.

Maintenance method: Adjust the feeding device to ensure that the material enters the crushing chamber evenly and stably; install an iron removal device, such as an electromagnetic iron remover or a permanent magnetic iron remover, in front of the crusher feed port to prevent non-crushed objects from entering the crusher. Once it is found that non-crushed objects have entered the crusher, the crusher should be stopped immediately and the foreign objects should be removed; check the clearance between the main shaft and the moving cone, and adjust it according to the requirements of the equipment manual. If the clearance is too large, it can be solved by replacing the matching parts of the main shaft or the moving cone; if the clearance is too small, it can be properly ground or processed; check the wear of the bearings regularly, and replace new bearings in time when the bearing wear reaches a certain degree. When installing the bearings, ensure that they are installed correctly and that the clearance of the bearings meets the requirements; check the equipment foundation, tighten the anchor bolts, adjust the position of the foundation pad, and ensure that the equipment foundation is firm and level. Reinforce the loose foundation; adjust the belt tension of the belt drive device to make the tension of each belt consistent. For belts that are severely worn, they should be replaced in time.

c. Spindle fracture

Cone Crusher

Fault phenomenon: The crusher suddenly stops running and cannot start normally. After disassembling the equipment for inspection, it is found that the spindle is broken.

Causes: Long-term overload operation causes the stress on the main shaft to exceed its fatigue limit; there are defects in the main shaft material, such as cracks and inclusions inside, which reduce the strength of the main shaft; the equipment is frequently started and stopped, resulting in a large impact load on the main shaft; non-crushed objects enter the crusher, generating a huge instant impact force, causing the main shaft to break; poor lubrication, the friction between the main shaft and the bearing generates high temperature, reducing the mechanical properties of the main shaft.

Maintenance method: Strictly operate according to the rated parameters of the equipment to avoid overload operation. Reasonably arrange production plans to reduce the frequent start and stop of equipment; when purchasing a crusher, choose equipment produced by regular manufacturers to ensure that the material quality of key components such as the main shaft is reliable. Before installing the equipment, perform flaw detection on the main shaft to check whether there are material defects; once the main shaft is found to be broken, a new main shaft should be replaced immediately. When replacing the main shaft, choose a main shaft with the same specifications and qualified quality as the original model, and install it strictly according to the installation process. After installation, the coordination between the main shaft and other components should be checked and debugged to ensure the normal operation of the equipment; strengthen the management of the lubrication system, regularly check the quality and quantity of the lubricating oil, and replace the deteriorated or contaminated lubricating oil in time to ensure good lubrication between the main shaft and the bearing.

2. Hydraulic system failure

Cone Crusher

a. Insufficient pressure in the hydraulic system

Failure phenomenon: The hydraulic system cannot reach the set working pressure, resulting in difficulty in adjusting the discharge port, failure of the overload protection function, or failure of the movable cone to rise and fall normally.

Causes: Damage or performance degradation of the hydraulic pump, such as wear of the internal parts of the pump and aging of the seals, resulting in insufficient flow and pressure of the pump; insufficient hydraulic oil or oil pollution, air, moisture, impurities, etc. mixed in the hydraulic oil, affecting the normal operation of the hydraulic system; hydraulic pipeline leakage, including loose oil pipe joints, broken oil pipes, damaged seals, etc.; Failure of pressure control components such as overflow valves, such as the overflow valve core stuck and the spring failed, resulting in the inability to adjust the pressure or the pressure is too low; damage to the hydraulic cylinder seal, resulting in internal or external leakage of the hydraulic cylinder.

Maintenance method: Check the working condition of the hydraulic pump. If there is any damage or performance degradation, the hydraulic pump should be replaced or the internal parts of the pump should be repaired in time. When replacing the hydraulic pump, choose a hydraulic pump with the same specifications and matching performance as the original model; check the oil quantity and oil quality of the hydraulic oil. When the oil quantity is insufficient, replenish the hydraulic oil that meets the requirements in time. If the hydraulic oil is seriously contaminated, all hydraulic oil should be replaced, and the oil tank, filter and other components should be cleaned to ensure the internal cleanliness of the hydraulic system; check the hydraulic pipeline, tighten the loose joints after finding the leakage site, and replace the broken oil pipe and damaged seals. Perform a pressure test on the pipeline to ensure that there is no leakage; check the pressure control components such as the overflow valve, clean the valve core, replace the damaged spring or seal, and readjust the pressure setting value of the overflow valve. If the pressure control component is seriously damaged and cannot be repaired, it should be replaced with a new component in time; check the seal of the hydraulic cylinder. If it is damaged, replace the seal in time. At the same time, check whether the inner wall of the hydraulic cylinder is worn or scratched. If there is a problem, the hydraulic cylinder should be repaired or replaced.

Cone Crusher

b. The oil temperature of the hydraulic system is too high

Fault phenomenon: During the operation of the hydraulic system, the oil temperature continues to rise, exceeding the specified normal working temperature range (generally 30-60℃), resulting in a decrease in the viscosity of the hydraulic oil, an increase in system leakage, and an increase in the wear of hydraulic components.

Cause: The hydraulic system runs at high load for a long time, and the hydraulic oil generates too much heat during the circulation of the system; the viscosity of the hydraulic oil is too high or too low, which will affect the heat dissipation performance and work efficiency of the system, resulting in an increase in oil temperature; cooler failure, such as blockage of the cooling water pipeline, non-rotation of the cooling fan, and serious dust accumulation on the heat sink, prevents the hydraulic oil from being effectively cooled; there is a serious leakage in the hydraulic system, and a large amount of hydraulic oil generates heat during the leakage process; the oil tank capacity is too small, and the heat dissipation area of the hydraulic oil is insufficient, resulting in an increase in oil temperature.

Maintenance method: Arrange production tasks reasonably to avoid long-term high-load operation of the hydraulic system. When operating in a high-temperature environment, the working intensity of the equipment can be appropriately reduced or the rest time of the equipment can be increased; according to the requirements of the equipment manual, select hydraulic oil with appropriate viscosity. If the viscosity of the hydraulic oil is too high, it can be replaced with low-viscosity hydraulic oil; if the viscosity is too low, it can be replaced with high-viscosity hydraulic oil; check the working status of the cooler, clean the blockage in the cooling water pipeline, repair or replace the damaged cooling fan, clean the dust and debris on the heat sink, and ensure that the heat dissipation effect of the cooler is good. Regularly maintain and service the cooler; check the leakage of the hydraulic system, repair the leaking parts in time, and reduce the leakage of hydraulic oil. Hydraulic components with serious leakage should be replaced; if the oil tank capacity is too small, consider replacing a large-capacity oil tank or adding auxiliary heat dissipation devices, such as adding heat dissipation fins or external radiators, to improve the heat dissipation capacity of the hydraulic oil.

3. Electrical system failure

Cone Crusher

a. The motor cannot start

Fault phenomenon: After pressing the start button, the motor does not rotate, the indicator light in the control cabinet does not light up, or an abnormal alarm signal appears.

Causes: Power failure, such as power outage, power line disconnection, loose terminal, blown fuse, etc.; motor failure, such as motor winding short circuit, disconnection, grounding, rotor bar breakage, bearing jamming, etc.; control circuit failure, such as contactor, relay and other control components damage, button switch failure, control line disconnection or short circuit; overload protection device action, such as thermal relay overload protection, current transformer protection, etc., resulting in circuit disconnection.

Repair method: Check the power supply system to confirm whether there is a power outage, check whether the power line is disconnected or loose, and replace the blown fuse. Use a multimeter or other tools to measure whether the power supply voltage is normal to ensure stable power supply; conduct a comprehensive inspection of the motor, use an insulation resistance meter to measure the insulation resistance of the motor winding, and determine whether the winding is short-circuited, disconnected or grounded. If the motor winding is damaged, the motor can be repaired or replaced according to the situation. Check whether the motor's rotor is broken or the bearing is stuck. If there is a problem, repair or replace it in time; check the control circuit, check whether the contactor, relay and other control components are damaged one by one, and repair or replace the damaged components. Check whether the button switch is normal, and repair or replace the failed button. Check whether the control circuit is open or short-circuited, use tools such as a multimeter to troubleshoot, and repair the faulty circuit; check the overload protection device, and check whether the thermal relay, current transformer, etc. are working. If the overload protection is activated, the cause of the overload should be found out. After troubleshooting, manually reset the thermal relay or other protection devices, and then restart the motor.

b. Abnormal motor operation

Fault phenomenon: The motor has unstable speed, excessive vibration, abnormal noise, and high temperature during operation.

Causes: The three-phase power supply voltage of the motor is unbalanced, resulting in unbalanced three-phase current of the motor, vibration and noise; the motor bearing is worn or poorly lubricated, resulting in heating of the bearing and increased vibration; the motor winding is partially short-circuited or broken, causing the motor output power to drop and unstable operation; the motor load is too large or stuck, exceeding the rated load of the motor, causing the motor to overload; the motor cooling system fails, such as the cooling fan is damaged and the vents are blocked, so that the motor cannot dissipate heat normally and the temperature rises.

Repair method: Use a multimeter to measure the three-phase power supply voltage of the motor to check whether the voltage is balanced. If the voltage is unbalanced, check the power supply line, transformer and other equipment to eliminate the power supply failure. Adjust the load distribution of the three-phase power supply to make the three-phase voltage as balanced as possible; check the wear and lubrication status of the motor bearings. When the bearings are severely worn, replace new bearings in time. Lubricate the bearings regularly, add or replace grease to ensure good lubrication performance of the bearings; test the motor windings, and use tools such as multimeters and insulation resistance meters to check whether the windings are short-circuited or broken. If a winding fault is found, the motor winding can be repaired or replaced according to the situation; check the load of the motor to eliminate the cause of excessive load or jamming. For example, clean the blocked materials in the crushing chamber, adjust the tension of the belt drive device, and ensure that the motor load is normal; check the cooling system of the motor, repair or replace the damaged cooling fan, clean the blockage of the vent, and ensure that the heat dissipation channel of the motor is unobstructed. Regularly maintain and service the motor cooling system to ensure that the motor operates within the normal temperature range.

3. Preventive maintenance measures for cone crushers

Cone Crusher

a. Regular inspection and maintenance

Check the operating status of the equipment daily, including the vibration, noise, temperature, feeding conditions, etc. of the crusher, and deal with abnormalities in time.

Check the oil quantity and oil quality of the lubrication system every week, clean the filter, and replace the deteriorated or contaminated lubricating oil. Check the pressure, oil temperature, and pipeline leakage of the hydraulic system, replenish the hydraulic oil in time, and repair the leaking parts.

Check the wear of the crusher liner every month, measure the size of the discharge port, and adjust or replace the liner in time according to the wear. Check the belt tension and belt wear of the transmission device, adjust the belt tension, and replace the belt with severe wear.

Carry out comprehensive inspection and maintenance of the equipment every quarter, including checking the matching clearance between the main shaft and the moving cone, the wear of the bearings, the tightness of the wiring terminals of the electrical system, the performance of the control components, etc. Repair or replace parts in time for the problems found.

b. Standardized operation and management

Operators should operate in strict accordance with the operating procedures of the equipment, be familiar with the performance, structure and working principle of the equipment, and strictly prohibit overloading and using the equipment beyond the scope.

Formulate a reasonable production plan to avoid frequent starting and stopping of the equipment and reduce the wear and fatigue of the equipment.

Strengthen the training and management of operators, improve the technical level and sense of responsibility of operators, and ensure the correct operation and maintenance of the equipment.

Cone Crusher

c. Optimize the working environment

Keep the workplace of the crusher clean and hygienic, regularly clean up the debris and dust around the equipment, prevent dust and debris from entering the crusher, and affect the normal operation of the equipment.

Control the humidity and temperature of the material to prevent over-humidified or overheated materials from entering the crusher, and prevent the material from sticking to the liner and crushing chamber, which will affect the crushing effect and the service life of the equipment.

Set up reasonable feeding devices and iron removal devices before the crusher feed port to ensure that the material enters the crusher evenly and stably, and prevent non-crushed materials from entering the crusher.

As an important equipment in industrial production, the common failures of cone crushers involve multiple systems such as mechanical, hydraulic, and electrical systems. By deeply understanding the causes of failures, mastering scientific and effective maintenance methods, and taking active preventive maintenance measures, it is possible to eliminate failures in a timely manner, ensure the stable operation of equipment, improve production efficiency, reduce production costs, and create greater economic and social benefits for enterprises. At the same time, with the continuous development of technology, the fault diagnosis and maintenance technology of cone crushers is also constantly updated and improved. Enterprises should keep up with the trend of technological development and continuously improve the level of equipment management and maintenance.