As a common primary crushing equipment in mining, building materials, metallurgy and other industries, jaw crushers are favored for their simple structure, convenient operation and large crushing ratio. However, there are many types and models of jaw crushers on the market. How to choose the right equipment is a key issue that every user needs to understand.

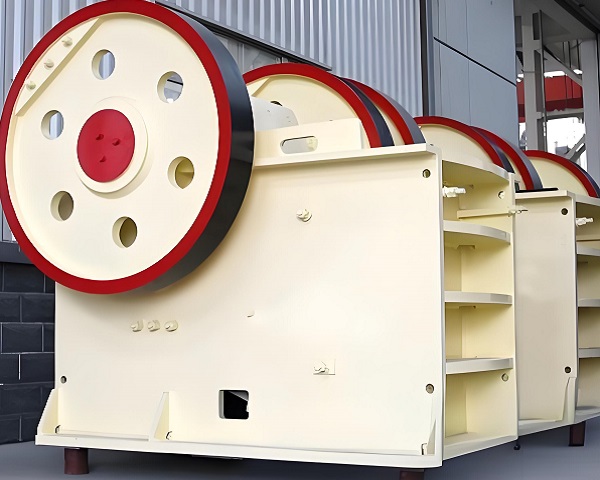

Jaw Crusher

1. Clarify your own needs

Before purchasing a jaw crusher, you must first clarify your own production needs, which is the basis and premise for purchase. To determine the type of material to be processed, the hardness, humidity, particle size and other characteristics of different materials vary greatly. Materials with higher hardness, such as quartz and granite, require extremely high wear resistance and pressure resistance of the crusher; and materials with higher humidity are prone to blockage of the crusher, affecting production efficiency. At the same time, it is necessary to be clear about the required output, and determine the processing volume that the crusher needs to achieve per hour or day according to the production capacity planning of its own production line, so as to avoid waste of resources or low production efficiency due to insufficient or excessive equipment capacity. In addition, the particle size requirements of the material after crushing must also be considered. Different production processes have different requirements for the particle size of the finished product, which is directly related to the model and configuration selection of the crusher.

Jaw Crusher

2. Pay attention to equipment performance parameters

The performance parameters of the equipment are important indicators to measure the quality and applicability of the jaw crusher. The size of the feed port determines the maximum size of the material that can be put in. The appropriate feed port specifications should be selected according to the actual material size. If the feed port is too small, the material cannot enter the crusher smoothly, affecting the production progress; if the feed port is too large, the equipment cost will increase. The crushing ratio reflects the degree of change in the particle size before and after the material is crushed. The larger the crushing ratio, the finer the particle size of the material after crushing. The size of the discharge port can be adjusted. By adjusting the size of the discharge port, the particle size of the finished material can be controlled. Therefore, it is necessary to select equipment with convenient and flexible discharge port adjustment. At the same time, the processing capacity and motor power of the equipment should match its own production needs. If the motor power is too small, the equipment cannot operate normally; if the motor power is too large, the energy consumption cost will increase. In addition, the speed of the crusher will also affect the crushing efficiency and product particle size. If the speed is too fast, the equipment may be aggravated. If the speed is too slow, the production efficiency will be reduced.

Jaw Crusher

3. Examine the quality and reliability of the equipment

The quality and reliability of the equipment directly affect the continuity and cost of production. High-quality jaw crushers are usually made of high-strength steel, such as high manganese steel, chrome-molybdenum alloy steel, etc. These materials have good wear resistance and pressure resistance, and can extend the service life of the equipment. The manufacturing process is also crucial. Advanced manufacturing technology can ensure the accuracy and assembly quality of each component of the equipment and reduce the failure rate during the operation of the equipment. The manufacturing process level can be examined by checking the welding quality, component processing accuracy, assembly process and other aspects of the equipment. In addition, it is also critical to understand the operating stability of the equipment. You can consult users who have used the equipment to understand whether the equipment has excessive vibration, excessive noise, frequent replacement of wearing parts and other problems during actual operation.

Jaw Crusher

4. Pay attention to after-sales service

Perfect after-sales service is a factor that cannot be ignored when purchasing a jaw crusher. During the use of the equipment, various faults and problems are inevitable. Timely and professional after-sales service can reduce equipment downtime and reduce production losses. Choose a manufacturer with a wide coverage of after-sales service network and fast response speed to ensure that when there is a problem with the equipment, it can get support from maintenance personnel in the shortest time. At the same time, the manufacturer should provide sufficient spare parts supply to ensure the timely replacement of wearing parts. In addition, the manufacturer should also provide services such as equipment installation and commissioning, operation training, regular maintenance and maintenance to help users use and maintain the equipment correctly and extend the service life of the equipment.

Jaw Crusher

5. Compare different brands and prices

There are many brands of jaw crushers on the market, and the price difference is also large. When purchasing, it is necessary to compare and analyze the products of different brands to understand the market reputation, product quality, after-sales service, etc. of each brand. Price cannot be used as the only criterion for purchase. Low-priced products may have defects in quality and performance, and the cost of later use will increase significantly. It is necessary to comprehensively consider the cost-effectiveness of the equipment and choose products that can meet their needs in terms of quality, performance, price and after-sales service. You can learn about the information of different brands of jaw crushers through online searches, industry exhibitions, friends' recommendations, etc., and make comprehensive comparisons and evaluations.

The above sorts out the key points of jaw crusher purchase from many aspects. If you want to learn more about a part of the content or have specific purchase needs, please feel free to talk to me.