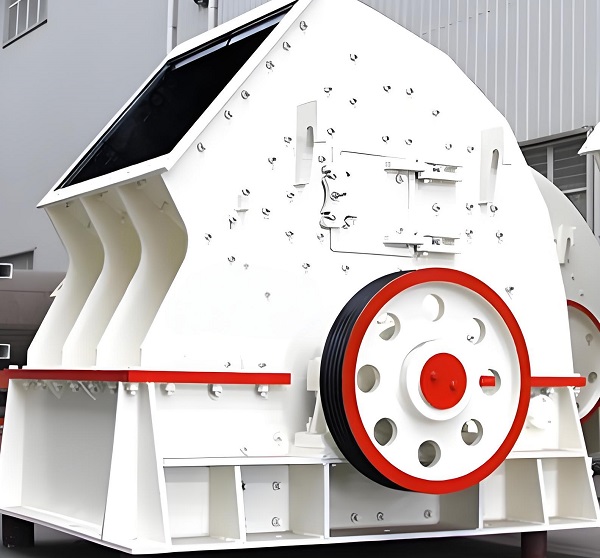

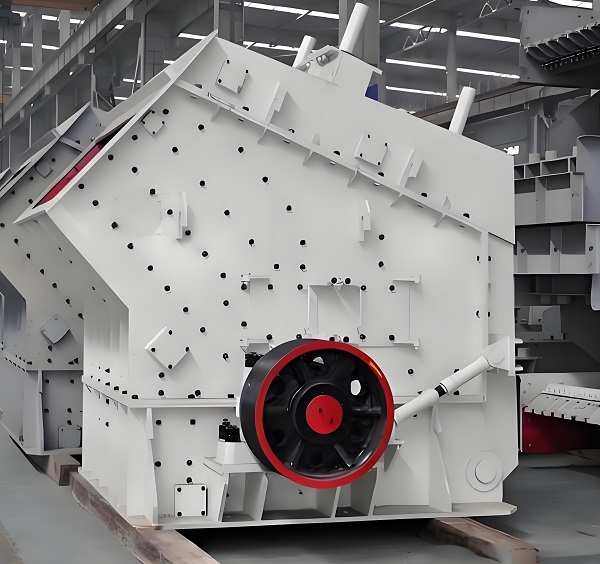

In mining, building materials, road construction, and other fields, crushing equipment is a core component of material processing. The impact crusher, with its unique operating principle and superior performance, has become the preferred equipment for many crushing scenarios. It utilizes impact energy as its primary crushing force, with the high-speed rotation of the rotor driving the hammers to impact, collide, and grind the material, ultimately achieving material crushing. The following detailed analysis of the core competitiveness of the impact crusher will examine its structural features, performance advantages, and application advantages, helping industry practitioners gain a more comprehensive understanding of its value.

Structural Design Features: Simple and Efficient, Easy Operation and Maintenance

The impact crusher's structural design takes practicality and maintainability into full consideration. The overall structure is relatively simple, consisting primarily of core components such as the rotor, hammers, impact plates, frame, feed inlet, and discharge port. The rational layout of these components ensures stable operation and ongoing maintenance.

The rotor, serving as the power transmission and impact core, is manufactured from high-strength alloy steel and undergoes a specialized heat treatment process, resulting in excellent impact resistance and a significantly extended service life. The rotor speed can be flexibly adjusted according to material characteristics and crushing requirements, ensuring efficient crushing of materials of varying hardness and particle size. The blow bars, the components that come into direct contact with the material, are made of high-chromium alloy, offering high hardness and excellent wear resistance. They are secured with wedges, making replacement quick and easy without the need for complex disassembly, significantly reducing downtime for maintenance.

The impact plate design is equally ingenious, typically employing a curved structure. This allows the material to undergo multiple impacts and rebounds within the crushing chamber, improving crushing efficiency while effectively controlling the output particle size. Furthermore, the gap between the impact plate and the blow bars can be precisely adjusted using an adjustment mechanism to meet the diverse particle size requirements of various industries. Furthermore, the machine's frame utilizes a one-piece welded structure, offering strong rigidity and stability. It can withstand the significant impact forces generated during crushing, preventing deformation that could affect normal operation.

For ease of maintenance, the impact crusher features a dedicated inspection door and observation window, allowing quick access to the interior of the machine for component inspection, replacement, and cleaning without disassembling the entire machine, significantly reducing maintenance complexity and labor intensity. The observation window allows real-time monitoring of the material crushing progress within the crushing chamber, enabling timely identification and resolution of problems such as material blockage and component wear, ensuring continuous and stable operation.

Performance Advantages: High Efficiency and Energy Saving, Excellent Crushing Results

1. High Crushing Efficiency and High Processing Capacity

The impact crusher utilizes the impact crushing principle. Upon entering the crushing chamber, the material is instantly broken into small pieces by the high-speed impact of the hammer. Simultaneously, the collision and grinding action between the impact plate and the material further refines the material, resulting in a fast and efficient crushing process. Compared to traditional jaw crushers, impact crushers offer a faster crushing rate and can increase processing capacity by 20%-30% for materials with a hardness below medium (such as limestone, granite, and concrete blocks). Taking limestone processing as an example, a medium-sized impact crusher (such as the PF-1214) can process 80-150 tons per hour, meeting the production needs of small and medium-sized building materials factories and mines. Large impact crushers (such as the PF-1520) can process up to 200-350 tons per hour, making them suitable for crushing materials in large-scale infrastructure projects.

Furthermore, the impact crusher's large feed opening and grate-free design effectively prevent material clogging. This ensures stable feeding and crushing efficiency, especially for materials with high moisture content or a certain degree of viscosity. This advantage makes the impact crusher particularly effective in processing special materials such as construction waste and coal gangue, further expanding its application range.

2. Energy Saving and Consumption Reduction, Low Operating Costs

In today's increasingly energy-scarce world, energy-saving performance has become a key concern for businesses, and impact crushers offer significant advantages in this regard. First, the equipment utilizes an optimized drive system, with the motor and rotor directly connected via a coupling. This results in high transmission efficiency and minimal energy loss, saving 10%-15% in electricity compared to belt-driven crushing equipment. Second, the crushing process primarily relies on impact energy, rather than compression, requiring relatively low crushing forces. Therefore, the motor power requirement is minimal, further reducing energy consumption. For example, when processing the same limestone output, the unit power consumption of an impact crusher is only 70%-80% of that of a jaw crusher. Over time, this can significantly save companies money on electricity costs.

Furthermore, the impact crusher's wearing parts (such as the hammer and impact plate) are made of highly wear-resistant materials, ensuring a long service life and a relatively short replacement cycle. Taking the blow hammer as an example, when processing low- to medium-hardness materials like limestone, the service life can reach 3,000-5,000 hours, while when processing harder materials like granite, the service life can reach 1,500-2,500 hours. Compared to traditional crushing equipment, this can reduce the frequency of wear part replacement by over 30%. This not only reduces the procurement cost of wear parts but also reduces downtime caused by component replacement, indirectly improving production efficiency.

3. Uniform output particle size and high product quality

For industries such as building materials and road construction, the output particle size and shape of materials directly affect the quality of subsequent products. Impact crushers offer unique advantages in this regard. Because the material undergoes multiple impacts, collisions, and grinding within the crushing chamber, the crushing process is more thorough, resulting in a uniform and well-graded output particle size that effectively meets the particle size requirements of various industries. By adjusting the gap between the impact plate and the blow hammer, the output particle size can be controlled within a range of 0-50mm, with a particle size acceptance rate exceeding 95%, far exceeding the particle size control accuracy of traditional crushing equipment. In addition, the impact crusher produces mostly cubic particles with minimal flakes, which is crucial for applications such as concrete aggregate and road base materials. Cubic particles offer excellent flowability and compaction properties, improving the strength and stability of concrete, enhancing the bearing capacity of road bases, and reducing the occurrence of later construction defects. For example, in gravel used in road construction, the flake content of crushed stone using an impact crusher can be kept below 5%, fully complying with the national standard for "Pebbles and Crushed Stone for Construction" (GB/T 14685-2022), providing a strong guarantee for project quality.

Application Advantages: Wide Range of Applications and Strong Adaptability

1. Strong Material Adaptability, Capable of Crushing a Wide Range of Materials

The impact crusher is highly adaptable and can efficiently crush a wide range of materials, from brittle materials (such as limestone, marble, and gypsum) to medium-hard rocks (such as granite, basalt, and quartzite), as well as recycled materials such as construction waste, concrete blocks, and coal gangue. This advantage is primarily due to its unique crushing principle and rational structural design: the impact crushing method effectively addresses the crushing needs of brittle materials and avoids over-crushing; while the high-strength component material and optimized crushing chamber structure can withstand the impact and wear caused by harder materials, ensuring stable operation.

In the mining industry, impact crushers are commonly used to crush non-metallic ores such as limestone and gypsum, reducing the raw ore to a particle size suitable for subsequent processing. In the construction and building materials industry, they are used to crush limestone in cement production lines and prepare aggregates in concrete mixing plants. In road construction, they can crush hard rocks such as granite and basalt to produce high-quality crushed stone for road base and surface layers. In construction waste management, they can crush waste concrete blocks and bricks into recycled aggregate, achieving resource recycling and aligning with China's green and environmentally friendly development philosophy.

2. Flexible Adaptability to Various Production Processes

The impact crusher can not only be used alone as the primary crushing device, but can also be combined with jaw crushers, cone crushers, sand making machines, and other equipment to form a complete crushing production line to meet diverse production needs. In primary crushing operations, if the material is hard and large in size, a jaw crusher can be used for primary crushing. After the material is reduced in size, an impact crusher can then be used for secondary and tertiary crushing, further improving crushing efficiency and product quality. In sand production, the impact crusher can be used as a tertiary crushing device, feeding the crushed material into a sand making machine for further processing. This completes a complete production line of "primary crushing - tertiary crushing - sand making," producing high-quality sand and gravel aggregate that meets construction sand standards.

In addition, impact crushers offer flexible installation options, allowing for either fixed or mobile installations depending on site conditions. Fixed installation is suitable for enterprises with fixed sites and large production scales, where the equipment is secured with a concrete foundation to ensure stable operation. Mobile installation utilizes a mobile crushing station, integrating the impact crusher, feeder, vibrating screen, and other equipment onto a mobile frame. This allows for flexible movement according to material storage locations, reducing material transportation costs. It is particularly suitable for highly mobile operations such as mining sites and construction waste disposal sites.

3. Environmental Advantages: Reduced Pollution, Complying with Green Development Requirements

With the country's increasing environmental protection requirements, the environmental performance of crushing equipment has become a key consideration when selecting equipment. Impact crushers also excel in this regard. First, the equipment generates low noise during operation, thanks to its optimized structural design and shock-absorbing devices. Shock pads are installed between the frame and the foundation to effectively absorb vibrations generated during operation, reducing vibration noise. Furthermore, the impact crushing method between the hammer and the material produces less noise than extrusion crushing. By adopting measures such as enclosed soundproofing enclosures, the equipment's operating noise level can be controlled below 85 decibels, meeting national noise emission standards for industrial enterprises and reducing noise pollution to the surrounding environment and workers.

Second, impact crushers offer advantages in dust control. Sealing devices can be installed at the feed and discharge ports to prevent dust from escaping during the crushing process. Furthermore, dust removal equipment such as pulse bag filters can be installed to collect and treat dust generated during the crushing process, keeping dust emission concentrations below 30mg/m³, meeting national atmospheric pollutant emission standards. Furthermore, when processing recycled materials such as construction waste, impact crushers can achieve resource recycling, reduce landfill volume, and minimize land use and environmental pollution. This aligns with the national carbon peak and carbon neutrality development goals and provides strong support for enterprises to achieve green production.

With its numerous advantages and features, including a simple structure, easy operation and maintenance, high efficiency and energy saving, excellent crushing performance, wide applicability, and excellent environmental performance, impact crushers play a vital role in various fields, including mining, construction, building materials, and road construction. With continuous technological innovation and upgrades, impact crushers will further develop in terms of intelligence, large-scale development, and greenness, providing even stronger equipment support for the high-quality development of the industry.