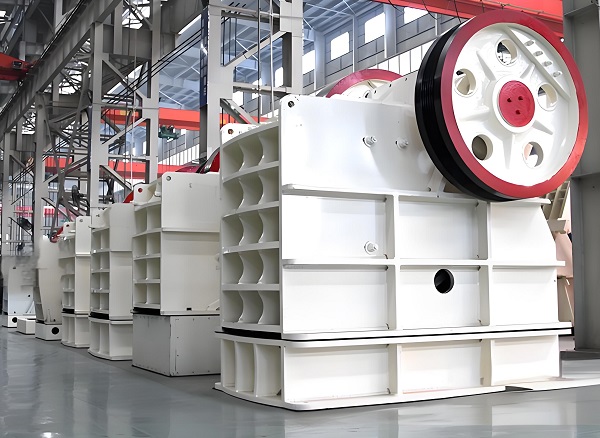

In the field of construction waste resource utilization, jaw crushers, as core equipment for concrete crushing, integrate multiple technologies from mechanical mechanics, materials science, and process design. Compared to crushing natural ore, concrete crushing presents unique challenges, including complex material composition, the presence of steel bars and impurities, and wide variations in hardness. The following systematically analyzes the complete concrete crushing process of a jaw crusher, revealing how it efficiently transforms waste concrete blocks into recycled aggregate.

Pretreatment Stage: Clearing Obstacles in the Crushing Process

The quality of pretreatment of concrete material before it enters the jaw crusher directly impacts crushing efficiency and equipment safety. This stage requires addressing three key issues: material size control, impurity separation, and moisture content adjustment.

Material sorting and cutting are the primary steps in pretreatment. Construction waste concrete blocks are often mixed with impurities such as steel bars, wood chips, and plastics. The presence of steel bars can cause the jaw crusher to jam or damage the movable jaw. The pre-treatment line must be equipped with magnetic separation equipment (magnetic field strength ≥12,000 gauss) to magnetically separate rebar with a diameter of ≤12mm. For densely packed reinforced concrete blocks, hydraulic shears are used to break the material into units weighing ≤50kg and with a side length ≤500mm. This size is based on a criterion of 80% of the jaw crusher's feed opening width (for example, for a PE-600×900 model with a feed opening width of 600mm, the optimal feed size should be ≤480mm). Practical data from a construction waste treatment plant shows that sorted concrete can increase the jaw crusher's operating efficiency by 20% and reduce the jamming rate by 80%.

Moisture content adjustment significantly impacts crushing performance. When the moisture content of concrete blocks exceeds 15%, they tend to form bonds during crushing, leading to blockage of the discharge opening. During the pretreatment stage, the moisture content must be reduced to below 10% through sun drying or hot air drying (controlled at 60-80°C). For materials collected during rainy weather, 0.5% quicklime can be added as a desiccant to neutralize the alkaline components in the concrete. Concrete blocks with a satisfactory moisture content can reduce jaw plate wear by 15% during crushing, and the fines content (particle size <0.075mm) in the finished aggregate is controlled to less than 3%.

Grading screening ensures material homogenization. A vibrating screen (200mm mesh size) at the end of the pretreatment line separates the concrete blocks into three grades: large blocks >200mm are returned for reshredding, medium blocks between 50-200mm are directly fed into the jaw crusher, and small blocks <50mm are pre-screened as finished products. This classification process ensures a more uniform particle size distribution of the material entering the crushing chamber, avoiding load fluctuations caused by the concentration of large pieces. The motor current fluctuation rate can be controlled within ±5%, far lower than the ±15% in unclassified conditions.

Crushing Stage: Mechanical Processes Within the Jaw Crusher

After entering the jaw crusher, the concrete block undergoes a complex crushing process involving extrusion, splitting, and grinding. This stage is controlled by the crushing chamber structure, the motion trajectory of the movable jaw, and the hydraulic system to achieve a balance between efficient crushing and impurity tolerance.

The initial extrusion in the feed area initiates the crushing process. When the concrete block falls into the jaw crusher's feed port (typically at a 60° angle), the wedge formed by the fixed and movable jaws begins to function. Driven by an eccentric shaft, the movable jaw oscillates periodically (small and medium-sized jaw crushers have an oscillation frequency of 250-350 times/minute), exerting a compressive pressure of 50-100 MPa on the material. This pressure must precisely match the compressive strength of concrete (typically 20-40 MPa) to ensure effective crushing while avoiding energy waste. For concrete blocks with a mortar layer attached to their surfaces, the shearing action in the feed zone first strips away the outer loose material, revealing the hard aggregate core.

Laminated crushing in the crushing zone is a key component. When the material enters the lower middle section of the crushing chamber (a critical area for deep-chamber designs), the meshing angle between the movable and fixed jaws (typically 20° for European-style jaw crushers) clamps the material and subjects it to multi-directional pressure, creating an "inter-material crushing" effect—inter-material compression and splitting, rather than simply colliding with the jaw plates. This crushing method reduces jaw plate wear (30% less wear than single-particle crushing) while also breaking the concrete blocks along the aggregate interface, preserving aggregate integrity. For materials containing small amounts of residual rebar, the laminating action squeezes the rebar into the interstices between the materials, preventing direct contact with the jaw plates and potential damage.

Particle size control in the discharge zone determines the quality of the finished product. After the crushing zone, the material enters the discharge opening (typically with an adjustable range of 50-150mm). The movable jaw's swing amplitude is reduced (the end stroke is approximately one-third of the feed end stroke), primarily through grinding to shape the aggregate. The impact plate at the discharge opening further adjusts the material flow rate, keeping the needle-like and flake content in the finished aggregate below 10%. If uncrushable hard objects (such as unsorted iron blocks) are detected, a hydraulic safety system temporarily expands the discharge opening by 20% within 0.3 seconds, automatically resetting after the foreign object is removed. This feature extends the jaw crusher's trouble-free operating time to over 120 hours when processing mixed materials.

Finished Product Processing: The Transformation from Crushed Product to Recycled Aggregate

The crushed product discharged from the jaw crusher undergoes multiple stages of processing to become recycled aggregate that meets construction standards. This stage focuses on particle size classification, secondary impurity separation, and performance optimization.

Screening and grading achieve aggregate standardization. The crushed product first enters a double-deck vibrating screen (upper screen mesh: 50mm, lower screen mesh: 20mm), where it is separated into three product grades: coarse material >50mm is returned to the jaw crusher for further crushing; medium material (20-50mm) is used as recycled coarse aggregate (for concrete basement); and fine material <20mm is fed into a sand making machine for further processing. An air separator installed during the screening process removes light impurities (such as plastic and wood chips) from the material, achieving a separation efficiency of over 95%. Through precise grading, a recycled aggregate production project has increased the grade compliance rate of finished aggregate from 70% to 92%.

Secondary magnetic separation for iron removal ensures aggregate purity. Even after pretreatment, fine steel bar fragments (less than 50mm in length) may remain in the crushed concrete aggregate, requiring secondary separation using a high-frequency magnetic separator (magnetic field strength of 8000 gauss). The magnetic separation drum speed is set at 1500 rpm, which removes iron impurities with a particle size of 2mm or greater, reducing the aggregate's iron content to ≤0.01%, meeting the requirements of GB/T 25177-2010, "Recycled Coarse Aggregate for Concrete." Recycled aggregates used in reinforced concrete require salt testing (chloride ion content ≤0.06%) and, if necessary, water washing to reduce the soluble salt content.

Particle shape optimization and strengthening enhance aggregate performance. Crushed recycled concrete aggregate typically has 10%-15% mortar dust attached to its surface. This requires surface treatment using a grinder (300-500 rpm) to remove the attached mortar and round the edges of the aggregate particles. After processing, aggregates must be tested for crushing value (should be ≤30%) and water absorption (controlled within 8%). Aggregates that do not meet these performance standards can be treated with silane impregnation (5% concentration) to form a waterproof membrane on the surface, reducing water absorption by more than 30%.

Equipment Adaptation and Process Optimization: Specially Designed for Concrete Crushing

The jaw crusher's high efficiency in crushing concrete stems from equipment modifications tailored to the material's characteristics and optimized process parameters. Technological innovation in this area directly determines the economic efficiency of the processing line.

The jaw plate material is specifically selected to address the abrasive nature of concrete. Sand and gravel aggregates in concrete can severely abrade the jaw plates. Conventional high-manganese steel jaw plates have a lifespan of only 100-150 hours under these conditions. Jaw plates, cast from a composite of high-chromium cast iron (Cr26) and high-manganese steel, achieve a working surface hardness exceeding HRC60 and a toughness of ≥15J/cm², extending their service life to 300-400 hours. The jaw plate's grid-like pattern enhances grip on concrete blocks, preventing slippage and improving crushing efficiency by 12%.

Dynamic adjustment of the movable jaw's motion parameters accommodates fluctuations in hardness. Concrete hardness varies with the original strength grade (C20-C80). The jaw crusher uses a variable-frequency motor to adjust the movable jaw's speed. When processing low-strength concrete (C20-C30), the speed is increased to 350 strokes/minute, using high-frequency impact to break up loose structures. When processing high-strength concrete (C60 and above), the speed is reduced to 250 strokes/minute to increase the single-shot crushing force. A certain intelligent crushing line uses a hardness sensor (with a detection accuracy of ±5 MPa) to automatically adjust the speed, keeping energy consumption fluctuations within ±8%.

Integrated dust removal and noise reduction systems meet environmental requirements. The concrete crushing process generates a large amount of dust (primarily composed of SiO₂). Negative pressure dust hoods (air volume 5000-8000 m³/h) are installed at the feed and discharge ports, along with bag filters (filtration accuracy 1μm) to maintain dust concentrations within the workshop at ≤2 mg/m³. The equipment foundation utilizes a combination of spring shock absorbers (damping coefficient 0.2) and a soundproof enclosure (insertion loss ≥30 dB) to keep noise levels below 85 dB, complying with the "Environmental Noise Emission Standards for Construction Sites."

The concrete crushing process of a jaw crusher is essentially a systematic process that transforms the material's form through mechanical force. Its efficiency and quality depend on the precise matching of pretreatment processes, equipment parameters, and material properties. With the increasing use of recycled aggregates in green buildings (currently exceeding 30%), jaw crusher concrete crushing technology is evolving towards intelligent features (such as AI-powered visual recognition of impurities), modularization (rapid switching of crushing modes), and low-energy consumption (specific energy consumption reduced to below 0.5 kW/h/ton). For construction waste treatment companies, mastering the technical key points of this process can not only improve economic benefits, but also provide core support for the construction of a circular economy system.