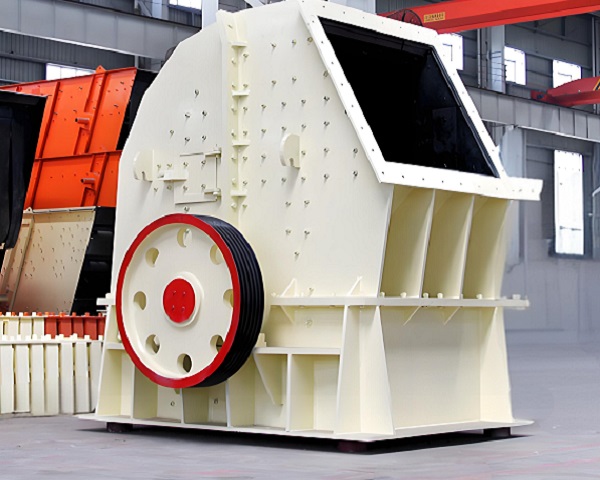

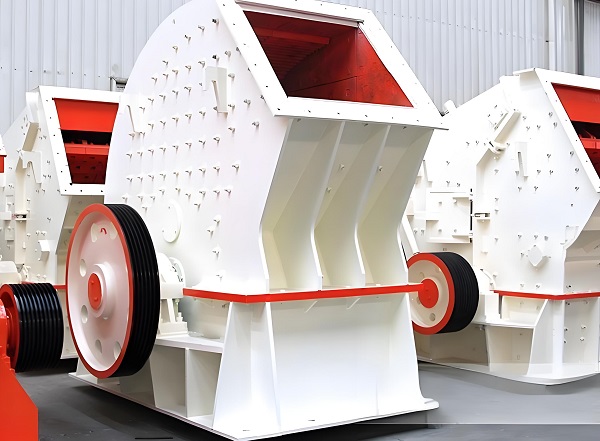

In numerous industrial sectors, such as mining, coal processing, construction and building materials, and chemical raw material processing, crushing equipment is a critical component of the material processing process. Hammer crushers, with their unique impact crushing principle and efficient material handling capabilities, have become essential equipment for crushing low- to medium-hardness materials. Their core working component, a high-speed rotating hammer, achieves rapid material crushing through the intense impact, collision, and grinding action of the hammer. This article comprehensively analyzes the core features and advantages of hammer crushers from multiple perspectives, including structural design, performance, application scope, and environmental protection and energy conservation, providing a professional reference for industry practitioners in selecting and using these crushers.

Structural Design Features: Simple and Compact, Easy to Maintain

The hammer crusher's structural design adheres to the principles of practicality, efficiency, and ease of maintenance. Its overall construction is relatively simple, consisting primarily of core components such as the housing, rotor, hammers, grates, feed inlet, and discharge port. The compact layout of these components not only saves installation space but also facilitates subsequent maintenance and inspection. The rotor, the core component of the hammer crusher, is constructed from high-strength cast steel or alloy steel and undergoes a quenching and tempering heat treatment process, resulting in excellent impact and deformation resistance. It can stably drive the hammers at high speeds (typically 900-1500 rpm). Multiple hammer mounting slots are evenly distributed across the rotor, and the hammers are secured to the rotor via pins or wedges, making installation simple, reliable, and easy to replace later. As a key component in direct contact with the material, the choice of material is crucial. Wear-resistant materials such as high-manganese steel (ZGMn13), high-chromium alloy, or multi-element alloy are typically used. High-manganese steel hammers offer excellent toughness and impact resistance, making them suitable for crushing materials with low hardness but high toughness (such as coal and limestone). High-chromium alloy hammers, with their high hardness and excellent wear resistance, are more suitable for crushing medium-hardness ores (such as shale and gypsum). Different hammer materials allow for flexible selection based on material characteristics, further expanding the equipment's applicability.

The grate bars are a crucial component in controlling the particle size of a hammer crusher. Installed at the bottom of the crushing chamber, the gap between the bars allows precise control of the particle size to meet the processing requirements of various industries. The bars are made of wear-resistant steel plate with a hardened surface, effectively resisting abrasive wear and extending their service life. Furthermore, their removable design allows for quick replacement or cleaning when worn or clogged, without disassembling the entire machine, significantly reducing maintenance and downtime.

The hammer crusher's casing is either split or openable, connected by bolts. Opening the casing provides direct access to core components within the crushing chamber, including the rotor, hammers, and grate bars, facilitating routine inspection, maintenance, and component replacement. Furthermore, the feed inlet is spacious, and some models are equipped with a feed guide to evenly guide material into the crushing chamber, preventing uneven wear caused by uneven material loading and further enhancing operational stability.

Performance Advantages: Efficient Crushing, Low Operating Costs

1. High Crushing Efficiency, High Processing Capacity

The hammer crusher utilizes a combined "impact + grinding" crushing method. Upon entering the crushing chamber, the material is first subjected to the intense impact of the high-speed rotating hammers, instantly breaking it into small pieces. The crushed material then moves downward under gravity, passing through the grate bars. Materials that meet the required particle size are discharged through the gaps between the grate bars, while those that do not meet the requirements are impacted and ground again by the hammers within the crushing chamber until they reach the acceptable particle size. This crushing method provides thorough and rapid material crushing, improving crushing efficiency by 30%-50% for medium- and low-hardness materials compared to traditional jaw crushers. Taking the common PC series hammer crushers as an example, the small PC-0808 hammer crusher has an hourly capacity of 10-20 tons, making it suitable for the crushing needs of small coal mines and building materials plants. The medium-sized PC-1210 hammer crusher has an hourly capacity of 50-80 tons, meeting the production requirements of small and medium-sized mines and chemical companies. The large PC-1615 hammer crusher has an hourly capacity of 150-250 tons, making it suitable for limestone crushing in large-scale infrastructure projects and cement plants. Furthermore, hammer crushers are highly adaptable to material moisture content. When the material moisture content is below 15%, they maintain stable crushing efficiency and are less likely to clog the grate. This advantage makes them particularly effective in crushing materials in humid environments.

2. Energy Saving and Consumption Reduction, Low Overall Cost

In the current industrial production landscape where cost reduction and efficiency improvement are key, the energy-saving advantages of hammer crushers have become one of their core competitive advantages. From an energy perspective, a hammer crusher's crushing process relies primarily on the impact energy of the hammers, rather than crushing them by compression. The crushing force required is relatively low, so the motor power does not need to be excessively high. For example, for the same coal output, a hammer crusher's unit power consumption is only 60%-70% of that of a jaw crusher. This saves 3-5 kWh of electricity per ton of coal processed, significantly reducing electricity costs over the long term.

Furthermore, the hammer crusher's wearing parts (hammers and grates) have a long service life and low replacement costs. For example, high-manganese steel hammers have a service life of 2,000-3,000 hours when crushing low-hardness materials like coal and limestone. Even for medium-hardness materials like shale and gypsum, the service life can reach 1,000-1,500 hours. Compared to the hammers in an impact crusher, they require less frequent replacement, costing only 50%-60% of the cost of hammer replacement. Furthermore, the equipment is easy to maintain, requiring no complex technical expertise. Routine maintenance can be performed by ordinary operators with minimal training, further reducing labor and maintenance costs.

3. Uniform output particle size and stable product quality

For industries such as coal, building materials, and chemicals, the uniformity of the output particle size directly impacts the quality and efficiency of subsequent processing. Hammer crushers offer significant advantages in this regard. Because the material undergoes multiple impacts from the hammers and screening by the grates within the crushing chamber, only material that meets the required particle size is discharged. This results in highly uniform and well-graded output particle size, with a particle size acceptance rate exceeding 90%.

For example, when using a hammer crusher to crush raw coal, adjusting the grate gap allows the output particle size to be controlled within a range of 0-20mm. The resulting coal particles are uniform in shape, free of overly large lumps, meeting the stringent coal particle size requirements of power plants and coal chemical companies, avoiding problems such as incomplete combustion and equipment clogging caused by uneven particle size. In the processing of construction sand and gravel, hammer crushers can crush raw materials such as limestone and shale into aggregates that meet construction sand standards. The resulting material has a uniform particle size and continuous particle gradation, effectively improving the strength and stability of concrete and ensuring the quality of construction projects.

Application Advantages: Wide Range of Applications and Strong Adaptability

1. Strong Material Adaptability, Capable of Crushing a Wide Range of Medium and Low Hardness Materials

Hammer crushers are highly adaptable to material characteristics such as hardness, toughness, and moisture content. They are primarily suitable for crushing medium and low hardness materials with a compressive strength below 150 MPa. This includes coal, limestone, shale, gypsum, gangue, construction waste, and chemical raw materials (such as fertilizer raw materials). They are widely used in various industries. In the coal industry, hammer crushers are core equipment for raw coal crushing. They crush raw coal into particle sizes suitable for use in coal washeries, power plants, and boilers, while also effectively breaking down gangue within the coal, thereby improving coal utilization. In the construction and building materials industry, they are used to crush raw materials such as limestone and shale, providing high-quality aggregate for the production of cement, concrete, and wall materials. In the chemical industry, they can crush fertilizer raw materials (such as phosphate rock and potassium feldspar) and plastic pellets to meet the particle size requirements of chemical product processing. In the field of construction waste management, they can crush discarded concrete blocks, bricks, and mortar into recycled aggregate, achieving resource recycling and aligning with China's green and environmentally friendly development philosophy.

It is worth noting that while hammer crushers are relatively limited in their crushing effectiveness for high-hardness materials (such as granite and basalt), they can be used in conjunction with jaw crushers to form a combined "coarse and fine crushing" process, which can also process some high-hardness materials. For example, using a jaw crusher to coarsely crush granite to a smaller particle size before using a hammer crusher for fine crushing not only improves crushing efficiency but also reduces equipment wear, further expanding the hammer crusher's application scenarios.

2. Flexible Adaptability to Various Production Processes and Installation Scenarios

Hammer crushers can not only be used independently as the primary crushing device, but can also be combined with auxiliary equipment such as feeders, vibrating screens, and conveyors to form a complete crushing production line to meet diverse production needs. In coal washing, hammer crushers combined with vibrating screens can achieve integrated "crushing + screening" operations. Crushed coal is directly fed to the vibrating screen for classification, selecting products of varying particle sizes and streamlining the production process. In building materials production, hammer crushers, combined with sand making machines, dust collectors, and other equipment, can form a sand and gravel aggregate production line, producing high-quality sand and gravel that meets construction sand standards while reducing dust pollution.

In terms of installation scenarios, hammer crushers offer great flexibility and can be installed in either a fixed or mobile configuration, depending on the specific site conditions. Fixed installation is suitable for enterprises with fixed sites and large production scales. Concrete foundations secure the equipment to the ground, ensuring stable operation. Mobile installation utilizes a mobile crushing station, integrating the hammer crusher, feeder, vibrating screen, and other equipment onto a removable frame. This allows for flexible movement according to material storage locations, reducing material transportation costs. This is particularly suitable for highly mobile operations such as mining sites and construction waste disposal sites. For example, in construction waste disposal projects, mobile hammer crushing stations can be driven directly to the waste dump site for on-site crushing and processing, converting the waste into recycled aggregate. This eliminates long-distance transportation and significantly reduces processing costs.

Environmental Advantages: Low Pollution, Compliant with Green Production Requirements

With the country's increasing environmental protection requirements, the environmental performance of industrial equipment has become a key consideration for enterprises. Hammer crushers offer excellent environmental performance, effectively reducing pollution during production, and complying with green production development requirements. In terms of noise control, the hammer crusher's casing features a double-layer design, with an inner wear-resistant lining and an outer sound-insulating material, effectively absorbing noise generated during operation. Furthermore, an elastic coupling connects the rotor and motor, reducing vibration and noise during transmission. Furthermore, some models of hammer crushers are equipped with a shock-absorbing device, which further reduces vibration and noise during operation by installing shock-absorbing pads between the base and foundation. These noise-reducing measures keep the hammer crusher's operating noise below 80 decibels, complying with the national "Environmental Noise Emission Standard for Industrial Enterprises at Factory Boundaries" (GB 12348-2022), and reducing noise pollution to the surrounding environment and operators. In terms of dust control, the hammer crusher's feed and discharge ports are equipped with sealing devices to effectively prevent dust from escaping during the crushing process. Furthermore, the equipment can be used in conjunction with dust removal equipment such as pulse bag filters to collect and treat dust generated during the crushing process, keeping dust emission concentrations below 20mg/m³, well below national air pollutant emission standards. Furthermore, the hammer crusher produces no wastewater during the crushing process, eliminating water pollution and further enhancing its environmental performance.

In terms of resource recycling, hammer crushers play an important role in construction waste treatment and coal gangue utilization. For example, crushing construction waste into recycled aggregate can be used to produce building materials such as recycled concrete and recycled bricks, reducing landfill volume and lowering land use. Crushing coal gangue can also be used to produce new wall materials or as fuel, effectively reusing the gangue as a resource and reducing solid waste emissions, thus aligning with the national carbon peak and carbon neutrality development goals.

Hammer crushers, with their numerous advantages and features, including a simple and compact structure, high crushing efficiency, low operating costs, wide applicability, and environmentally friendly performance, have established a significant position in various sectors, including coal, building materials, chemicals, and construction waste disposal. With continuous technological innovation, hammer crushers will see further upgrades in hammer head material, structural optimization, and intelligent control. In the future, they are expected to achieve breakthroughs in crushing higher-hardness materials and achieving more refined particle size control, providing even stronger equipment support for the industry's high-quality development.