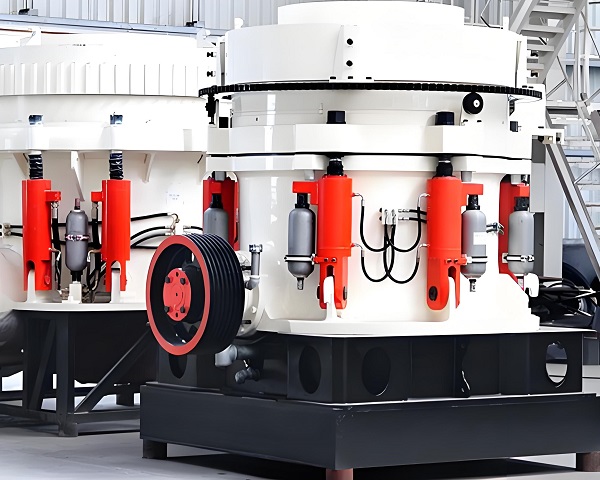

This article, drawing on practical industry experience, elaborates on the classification of cone crushers by application, their specific uses in various fields, and the types and characteristics of materials they are suitable for, providing comprehensive technical reference for production selection and process planning.

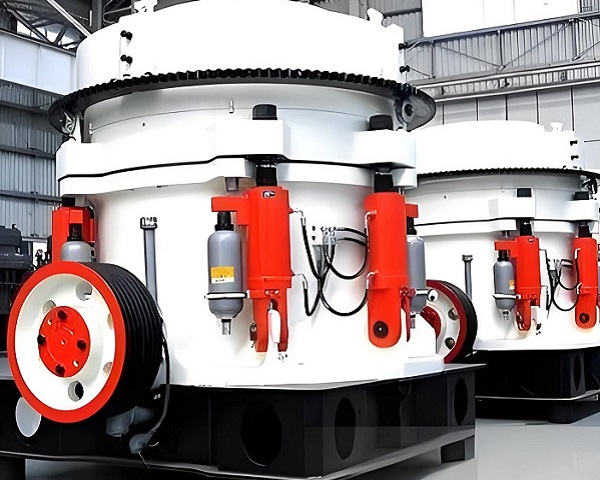

This article, combining the structural characteristics of the European-style cone crusher and practical field experience, elaborates on its installation process, key points, and maintenance strategies. It provides comprehensive technical guidance for on-site operations, ensuring the long-term safe and efficient operation of the equipment.

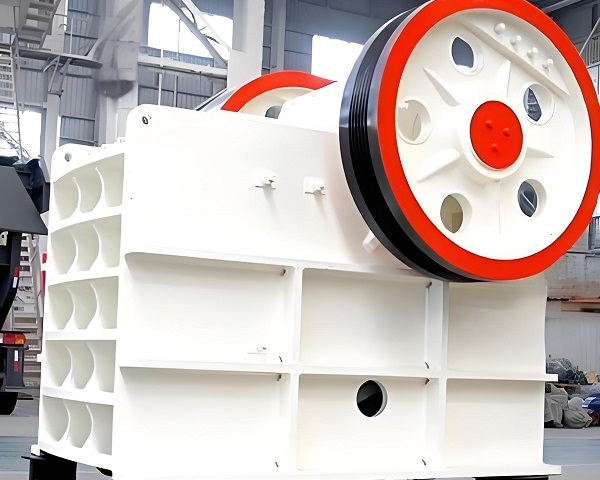

A thorough analysis of the characteristics and advantages of the European-style jaw crusher, clarifying its application advantages compared to traditional models, has important guiding significance for enterprises' equipment selection and production upgrades.

Improving the crushing efficiency of jaw crushers is a systematic project that requires coordinated efforts from multiple dimensions, including equipment selection, feed control, parameter optimization, maintenance, and technological upgrades.

This article will systematically dissect the structural features and technical advantages of the hydraulic cone crusher, and explain its value in combination with actual application scenarios, providing technical reference for high-end recycled aggregate production projects.

This article will systematically analyze the technical characteristics, application scenarios, core advantages, and combination solutions of various types of equipment, providing a comprehensive reference for construction waste crushing projects.

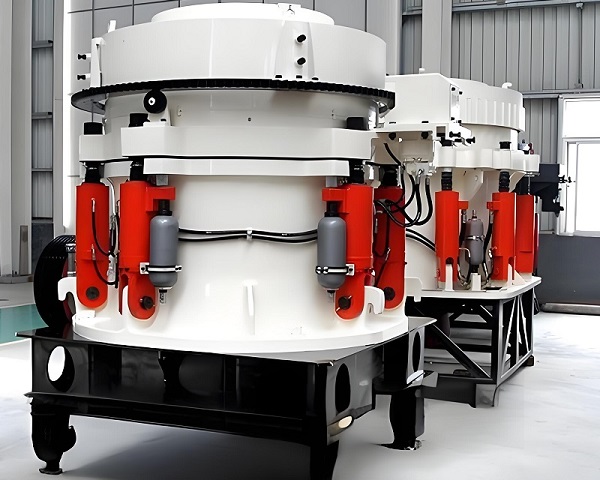

The maintenance of cone crushers should follow the principle of first identifying the root cause, then precise repair, and finally long-term prevention. Based on different types of faults and the structural characteristics of the equipment, maintenance plans should be developed. At the same time, a prevention system should be established through daily inspections, regular maintenance, and personne...

Cone crushers play a crucial role in industrial crushing, assisting in ore processing, aggregate production, waste recycling, and engineering support, thus providing support for multiple industries.

When purchasing a hammer crusher, you need to consider your own production needs and comprehensively consider multiple factors such as equipment parameters, material performance, manufacturer strength, and after-sales service to ensure that the equipment you choose can not only meet your current production needs but also have the potential for long-term stable operation.

Hammer crushers are widely used in multiple industrial fields, providing key support for large-scale production and efficient resource utilization in various industries. They are classic equipment in the field of industrial crushing that combines practicality and economy.