In the future, three-dimensional compound crushers will continue to play a core role in the fields of construction waste resource utilization, comprehensive mining processing, solid waste reduction, etc., becoming a key force in promoting the transformation of the industrial crushing industry and providing important support for various industries to achieve efficient resource utilization and susta...

In heavy industries such as mining, construction and building materials, metallurgy and chemical industry, material crushing is the "first checkpoint" in the production process. Its efficiency and crushing quality directly determine the smoothness of subsequent processes and the value of the final product.

The fine crusher eliminates screening obstacles through its crushing function, improves resource recovery efficiency, reduces the cost of the entire chain, and ultimately promotes the transformation of waste management to a "circular economy".

This article will provide a 2,000-word detailed guide from four dimensions: "demand analysis → equipment selection → manufacturer screening → procurement implementation" to help companies avoid purchasing misunderstandings and choose cone crushers with strong adaptability and high cost-effectiveness.

Hammer crushers occupy an important position in many fields such as coal, building materials, chemicals, and construction waste treatment due to their simple and compact structure, high crushing efficiency, low operating cost, wide range of applications, and good environmental performance.

Impact crusher failures are mostly related to component wear, improper operation, and untimely maintenance. By accurately identifying the type of failure, analyzing the cause, taking professional maintenance measures, and establishing a comprehensive daily maintenance and prevention system, the failure rate can be effectively reduced and the service life of the equipment can be extended.

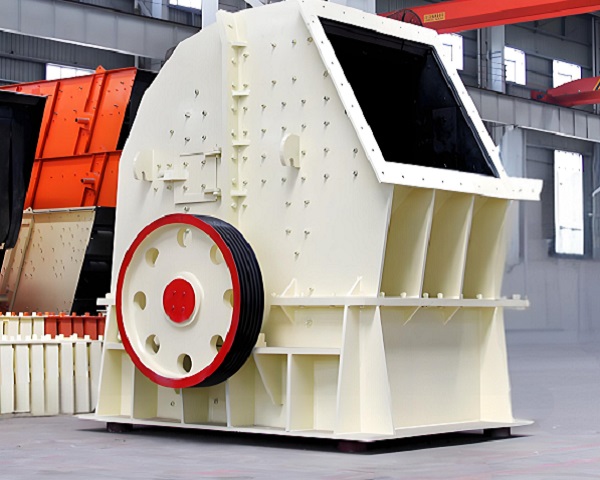

Impact crushers, with their numerous advantages and features, including simple structure, easy operation and maintenance, high energy efficiency, excellent crushing performance, wide range of applications, and environmental performance, play an important role in various fields such as mining, construction, building materials, and road construction. With continuous technological innovation and upgr...

Concrete crushing with a jaw crusher requires pretreatment, crushing, and finished product processing, along with equipment adaptation and process optimization. Pretreatment includes sorting and cutting, moisture content adjustment, and grading screening. The crushing stage involves extrusion in the feed area, lamination crushing in the crushing area, and particle size control in the discharge are...

Compared to traditional jaw crushers, it achieves multiple breakthroughs in structural optimization, performance improvement, and energy consumption control, particularly in hard rock crushing and high-capacity applications. The following analysis, focusing on its technical features and core advantages, provides a reference for selection decisions.

The selection of jaw crusher is a systematic project. It requires a comprehensive decision based on a full understanding of one's own needs, combined with factors such as equipment performance, manufacturer strength, and cost-effectiveness.